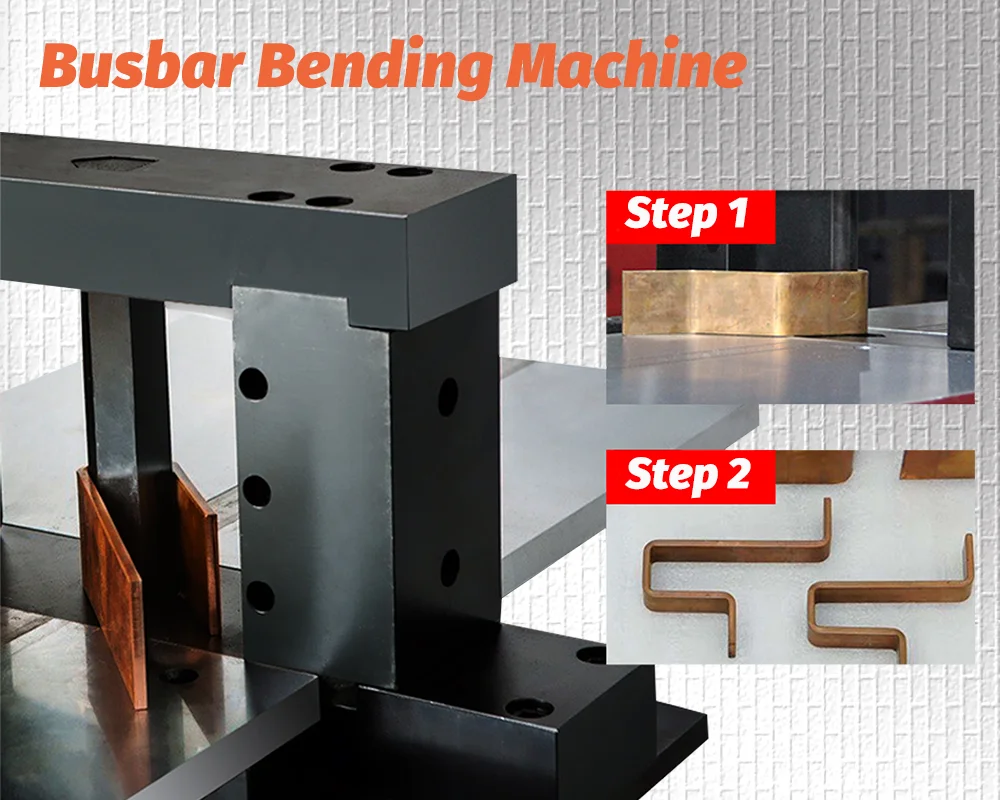

Some Points of Busbar Bending Machine

Main points of bending work for Busbar Bending Machine

(1) The parameter settings must match the installed mold (the mold selection in the CNC touch screen must be replaced after the mold is replaced).

(2) The embossing operation without placing the copper bar is prohibited.

(3) The rotation of the bending die must be in place.

(4) It is forbidden to put your hand into the mold when the mold is working.

Explanation of terms of CNC touch screen for bending station:

【Copper bar thickness】: The actual thickness of the processing material.

【Angle setting】: Set the forming angle of the processing material.

【Elasticity compensation】: Due to different materials, after the external force of molding is withdrawn, the angle will change due to different degrees of elasticity.

The correct setting of the elastic compensation angle can make the workpiece elastically return to the required workpiece angle after the molding is completed.

Elastic compensation = set angle - actual angle, when the set angle is less than the actual angle, the elastic compensation is a negative number,

and when the set angle is greater than the actual angle, the elastic compensation is a positive number (range -15.00 degrees ~ 15.00 degrees).

【Pressure holding time】: It refers to the dwell time after stepping on the foot switch in automatic state, after the time is reached, the mold returns to its original position. (Range 0.0S ~ 60.0S)

[Type 40 mold]: When the thickness of the copper bar is less than 5mm (including 5mm), please use the type 40 mold.

[Type 80 mold]: When the thickness of the copper bar is more than 6mm (including 6mm), please use the type 80 mold.

【Type Mould】: Use this option when customers customize special molds.

[Positioning front limit]: The bending die work advances to the set positioning front limit (Note: In the angle bending mode, the system automatically generates the positioning front limit after the parameter calling screen is set).

【Current position】: The current position of the bending die.

[Processing starting point]: The starting position when the bending die starts to work (Note: The processing starting point value must be less than the positioning threshold value,

setting the processing starting point can save the time of each processing cycle and improve the production efficiency).

【Counting of finished products】: Automatically calculate the number of processed pieces.

[Installation distance]: After the die returns to zero, the distance between the top die vertex and the die opening plane.

【die width】: the distance between the two stress points of the die when the copper bar is bent.

【Die support radius】: The actual radius of the edge arc of the die.

【Punch radius】: The actual radius of the top arc of the punch.

【Inertia compensation】: It is used to compensate the bending angle error caused by inertia when the cylinder moves forward.

[Oil pump sleep delay]: The automatic stop time of the oil pump (no one operates the equipment within the set time, and it will automatically stop when the set time is reached).

【Down time of punching】: By setting the down time of punching, set the down distance of the upper die, and adjust the die entry amount.

【Cut down time】: Set the down distance of the upper scissors by setting the cutting down time.

【Inching time】: By setting the inching time, adjust the forward distance when the mold is fine-tuning.

KEYWORDS for BUSBAR MACHINE

3 in 1 busbar machine busbar punching machine busbar bending machine busbar processing machine Busbar processing machine

Busbar machine ehrt punching machine busbar forming busbar machine manufacturers busbar machine price busbar machine korea

busbar machine china busbar machine hs code busbar machine manual busbar machine for sale 3 in 1 busbar machine

ehrt busbar machine namsung busbar machine alfra busbar machine moti busbar machine boschert busbar machine woojin busbar machine

cnc busbar machine jingpeng busbar machine hydraulic busbar machine busbar bending machine busbar punching machine

busbar cutting machine busbar processing machine busbar cutting punching and bending machine busbar bending machine manual

busbar bender machine busbar fabrication machine busbar bending and punching machine busbar bending machine manufacturer in ahmedabad