The 2024 version of the MOTI busbar machine with the latest design and development has begun to be launched.

At MOTI INDUSTRIAL, we provide businesses of all sizes with the latest copper busbar and aluminum busbar fabrication equipment.

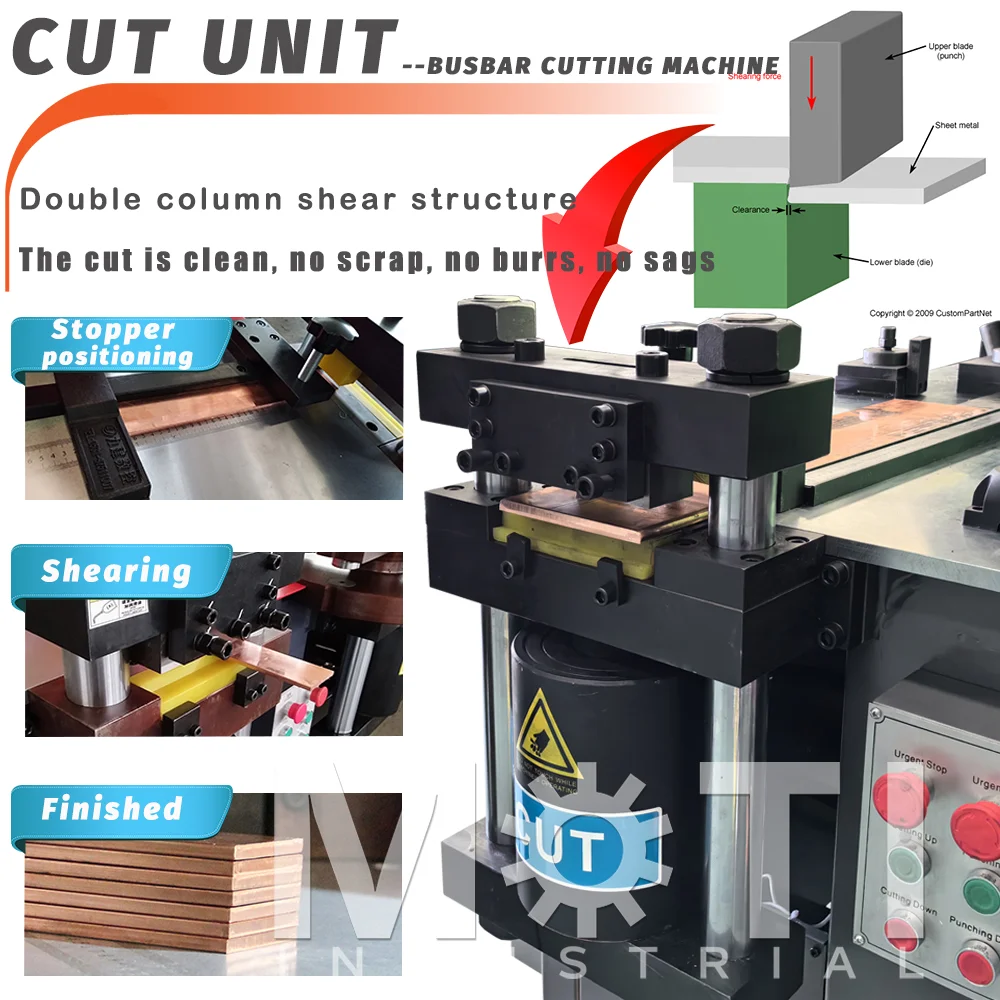

Cut Unit of CNC Busbar Processing Machine MOTI-30-3NC

The cut unit of the MOTI Busbar Machine plays a crucial role in ensuring precise and efficient busbar processing, particularly in the tasks of cutting copper or aluminum busbars to the required lengths for various applications.

1. High Precision Cutting

Measuring ruler by moving the horizontal axis guide bar, fix it according to the figure to cut, and cut.

2. Reduction of Material Waste

The cutting unit adopts a double-column structure shearing method, which can ensure precise cutting to minimize material waste and reduce the possibility of over-cutting or under-cutting.

It improves material utilization and reduces waste, thereby reducing overall production costs.

When using high-cost materials such as copper and aluminum, effective use of materials is particularly important.

3. Cutting can be done up to T15x160 mm.

Innovative punching system

1. The six-position turret punching mode is innovatively designed to shorten working time and improve work efficiency,

because there is no need for unnecessary work such as frequent replacement of punching fixtures.

2. Coordinate axis positioning method

Using the guide rails on the left, right and rear sides, large-capacity punching operations can be performed on any part of the 160 mm busbar.

3. It is also designed with Laser Light Positioning and Punching Pin Positioning methods.

Due to the effective arrangement of the scale, the positioning of the busbar punching can be controlled by checking the scale.

4. Punching can be done up to T15x160mm

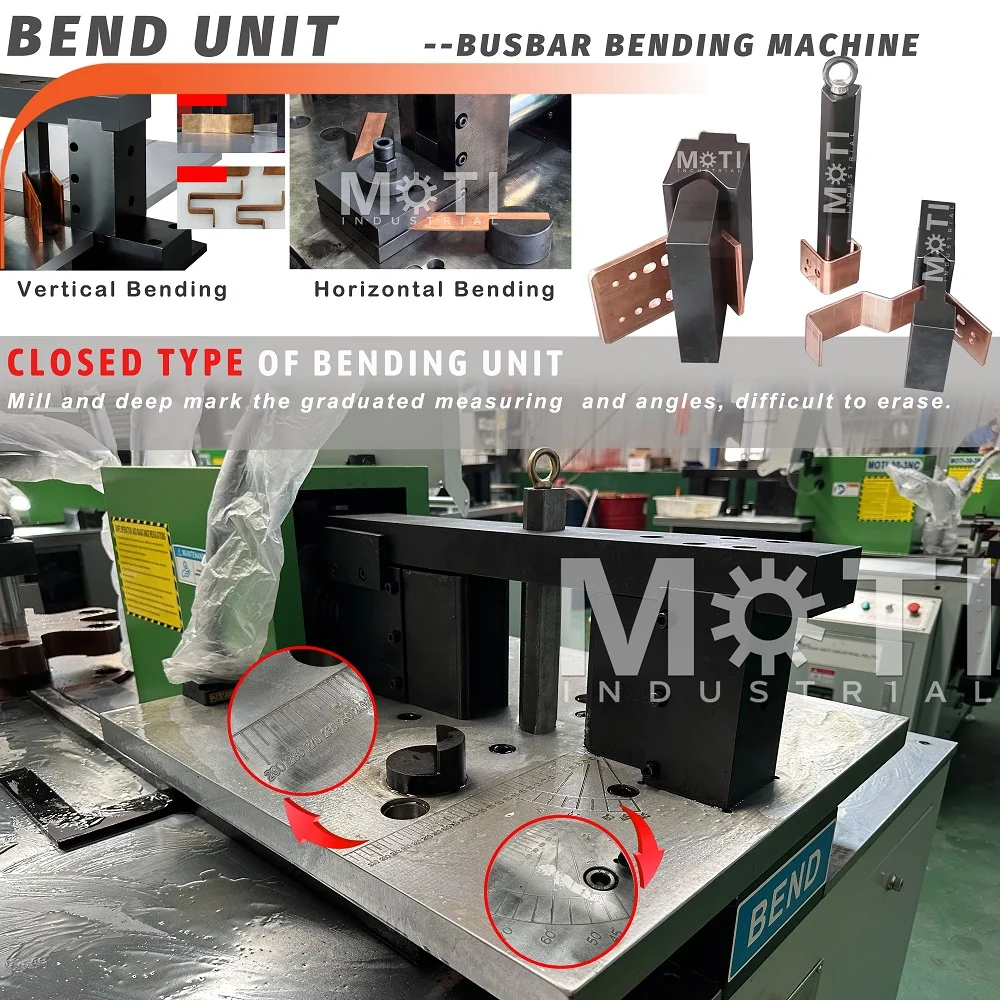

Busbar bending (manual and automatic)

1. SIEMENS Control System with 7'' Touching Screen

Workers can bend the required copper busbar thickness and angle during automatic operation (optional).

(Depending on the material of the busbar, the angle may not be completely accurate. In this case, it can be adjusted through the elastic compensation function)

2. The workbench is engraved with the bending angle to facilitate manual angle bending

#1. The bending angle is engraved on the bending table

Workers can manually bend the copper busbar according to the bending angle of the table by controlling the bending stroke of the machine

#3. The engraving depth is large to ensure that the copper busbar and the workbench are not erased or unclear due to long-term friction

#4. Complete bending molds

The standard configuration of the machine includes a small bending mold with a thickness of 1-5mm ( R3mm Vertical Bending Tools ),

a large bending mold with a thickness of 6-12mm ( R5mm Bending Tools ), a special bending mold for U-bend, an edage bending molds,

and an embossing mold. The complete bending mold configuration can meet the needs of most customers.

3. Display for the Closed Typed of the Bending Section of MOTI-30-3NC

The advantage of the closed structure of the bending unit is that it can ensure that the upper and lower parts of the copper busbar maintain the same force during the copper busbar bending process,

thereby ensuring that the overall degree of the completed bent copper busbar sample remains consistent and improving the bending accuracy.

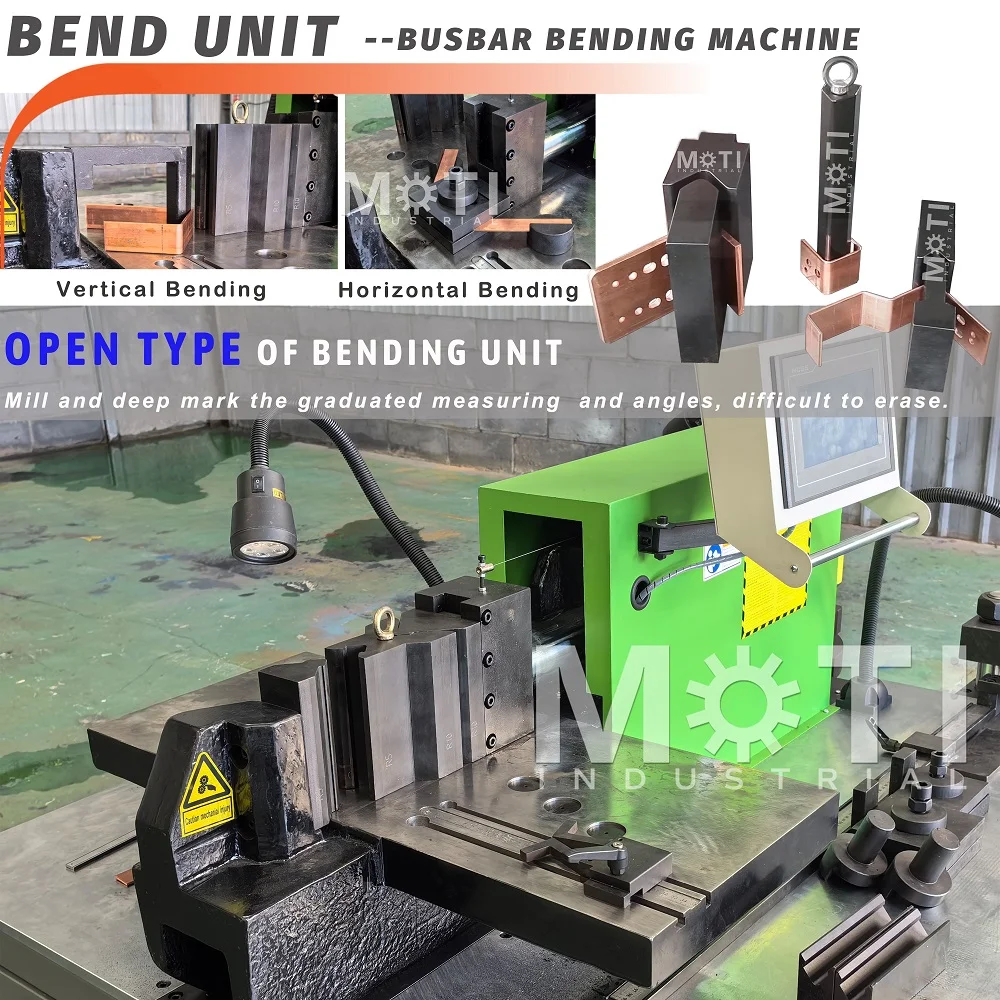

4. Display for the Open Type of the Bending Unit of MOTI-30-3NC

The advantage of the open structure of the bending unit is that it is convenient for the staff to take the copper busbar when the copper busbar is bent.

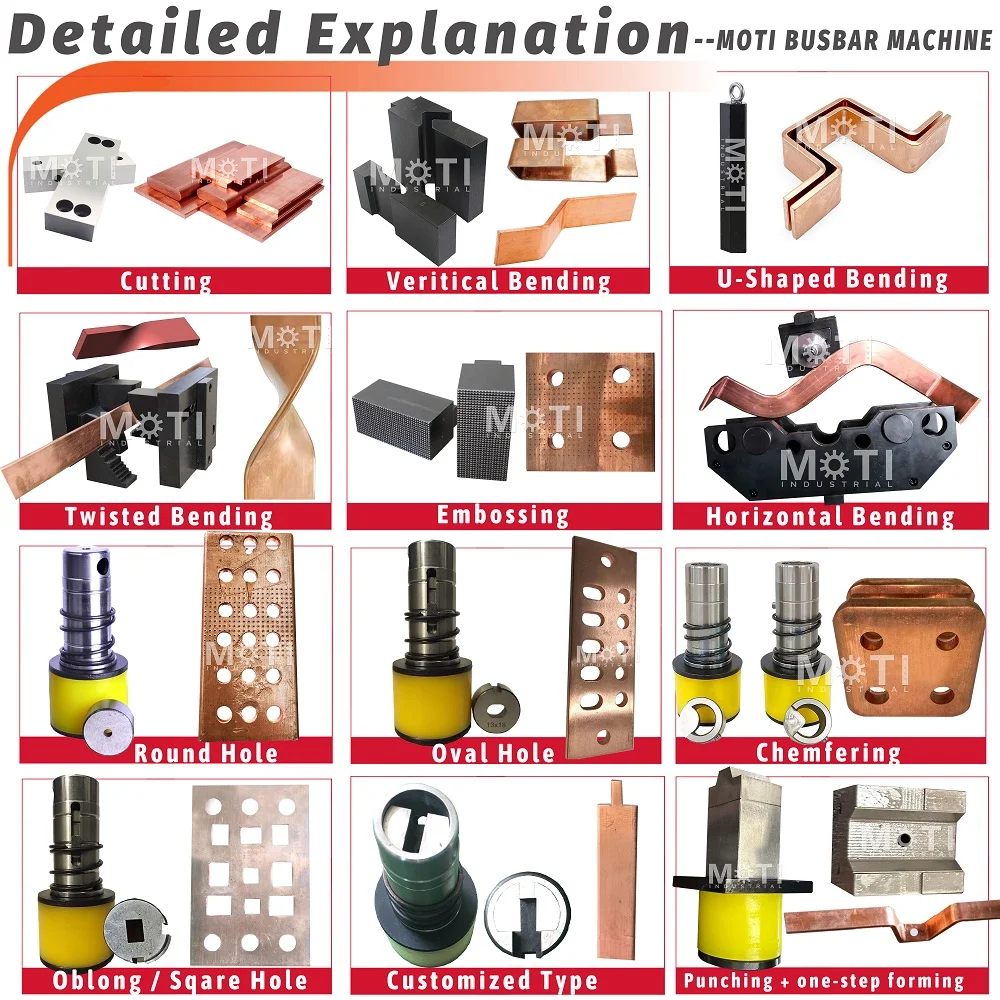

A detailed explanation of the busbar machine tools and Copper Busbar samples