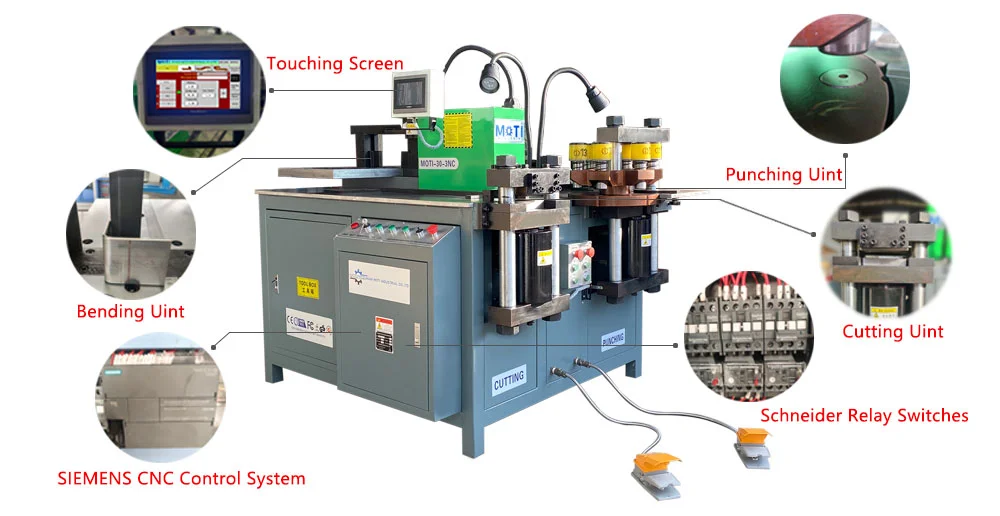

Powered by three separate hydraulic power packs

1. CUT--Double column shear structure

The shearing position adopts a double pillar structure with flat shears, no waste, no burrs, and no collapse feet.

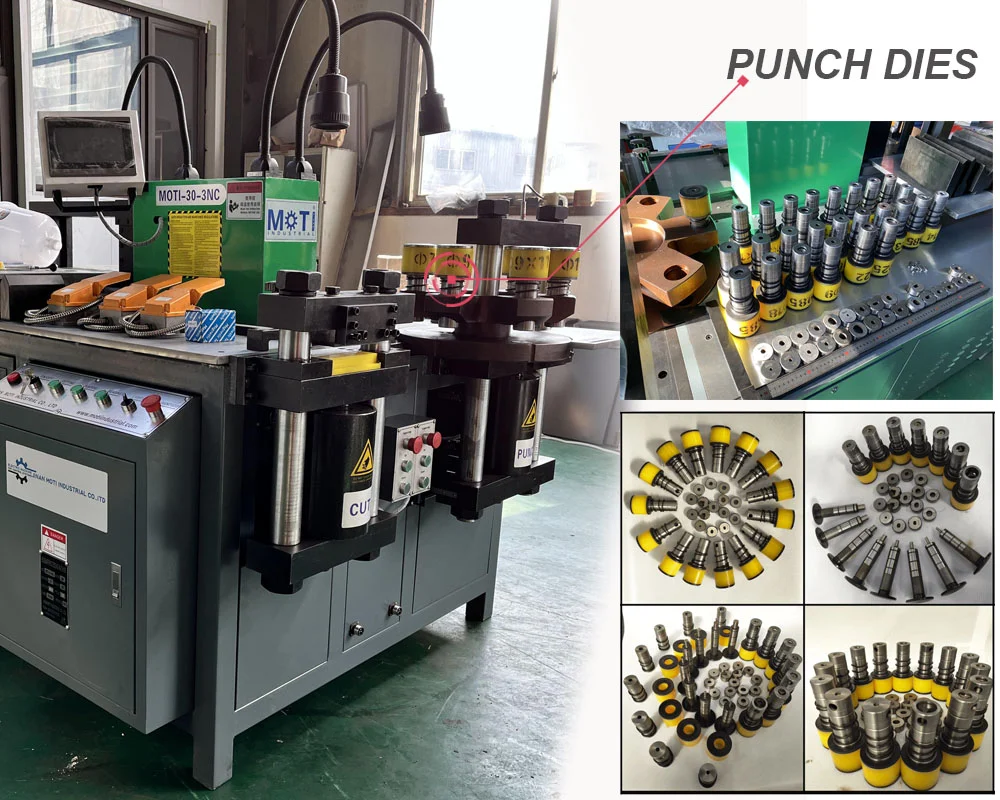

2. PUNCH--the united six-mode turnplate in tooth shape

(1) Three positioning methods: Laser pointer / Coordinate axis positioning / Positioning pin help to find the center of holes easily in the punche

(2) 6 sets of punching die to install turnplate. No need to change molds frequently

3. BEND-- Control by SIEMENS system

(1) Programmable meter systems cause high accuracy in bending

(2) Can finish Vertical Bending / Edge Bending ( Horizontal/Flat Bending ) / Z shaped Bending / U shaped Bending / Embossing / Twisted Bending, etc.

(3) Only need to input data, the machine will run automatically.

#1. cut section with double column structure

#2. cutting without scrap

#3. cutting interface smooth, no burrs, no collapse

PUNCH SECTION of MOTI BUSBAR PROCESSING MACHINE

#1. Punching unit adopts nodular cast iron material turret punching structure which is a totally a whole one,improving concentric degree of molds

#2. Adpot a six molds position integral turntable made of ductile iron materials

#3. Extend punch die life

#4. Saving frequency and time in replacing punching dies

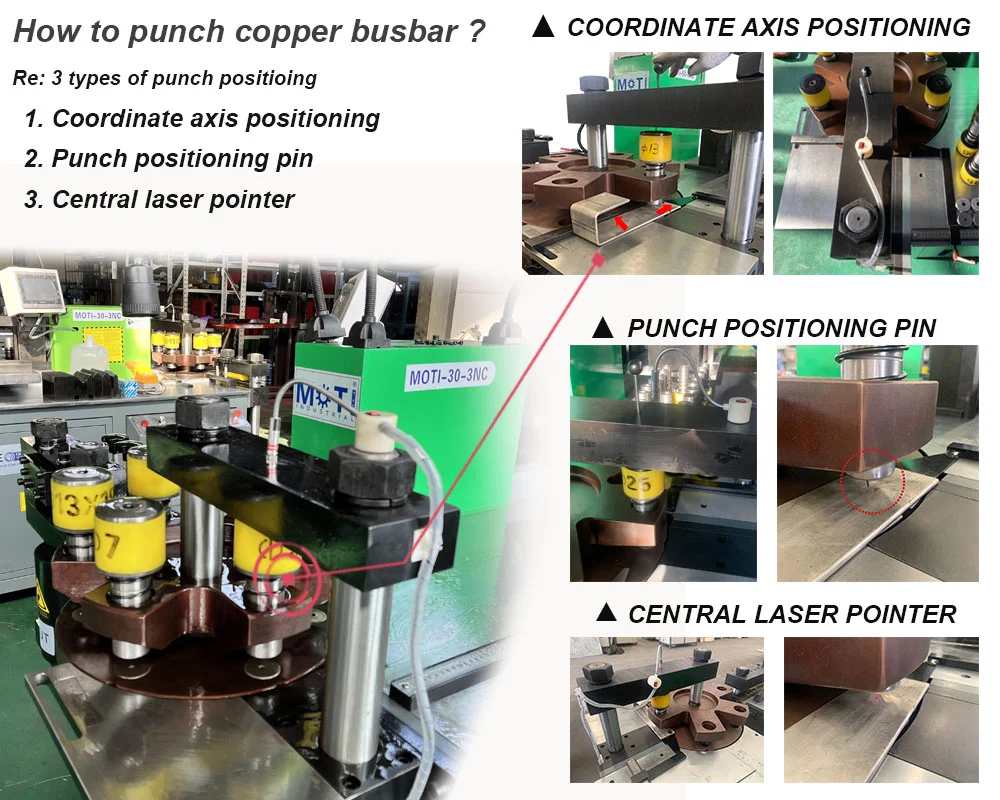

How to punch copper busbar by MOTI BUSBAR PROCESSING MACHINE?

There're 3 types of punch positioning from MOTI Busbar Machine

#1. Coordinate axis positioning

#2. Punch positioning pin

#3. Central laser pointer

PUNCH DIES of MOTI BUSBAR PROCESSING MACHINE

BEND SECTION of MOTI BUSBAR PROCESSINGMACHINE

#1. By changing the mold, it can also achieve a variety of processing functions, such as embossing, flattening, twist twist twist, etc.

#2. Busbar Bending Machine has two operation modes: a manual button and footswitch.

The operation is simple, and the generally skilled workers can use and operate it easily.

#3. MOTI Busbar Machine adopts closed bending, and the force point and the force point are connected by a beam with a thickness of 50 mm.

The mechanical strength is greatly enhanced compared with the open bending.

The bending angle can be numerically controlled. “Z-bend” can automatically calculate the required angle by inputting the vertical height (H) and bevel length (L) of the upper and lower planes.

In the working process, it is convenient to process the workpiece by inputting the corresponding angle and the thickness of the bus bar, and it has the function of memory and error compensation.

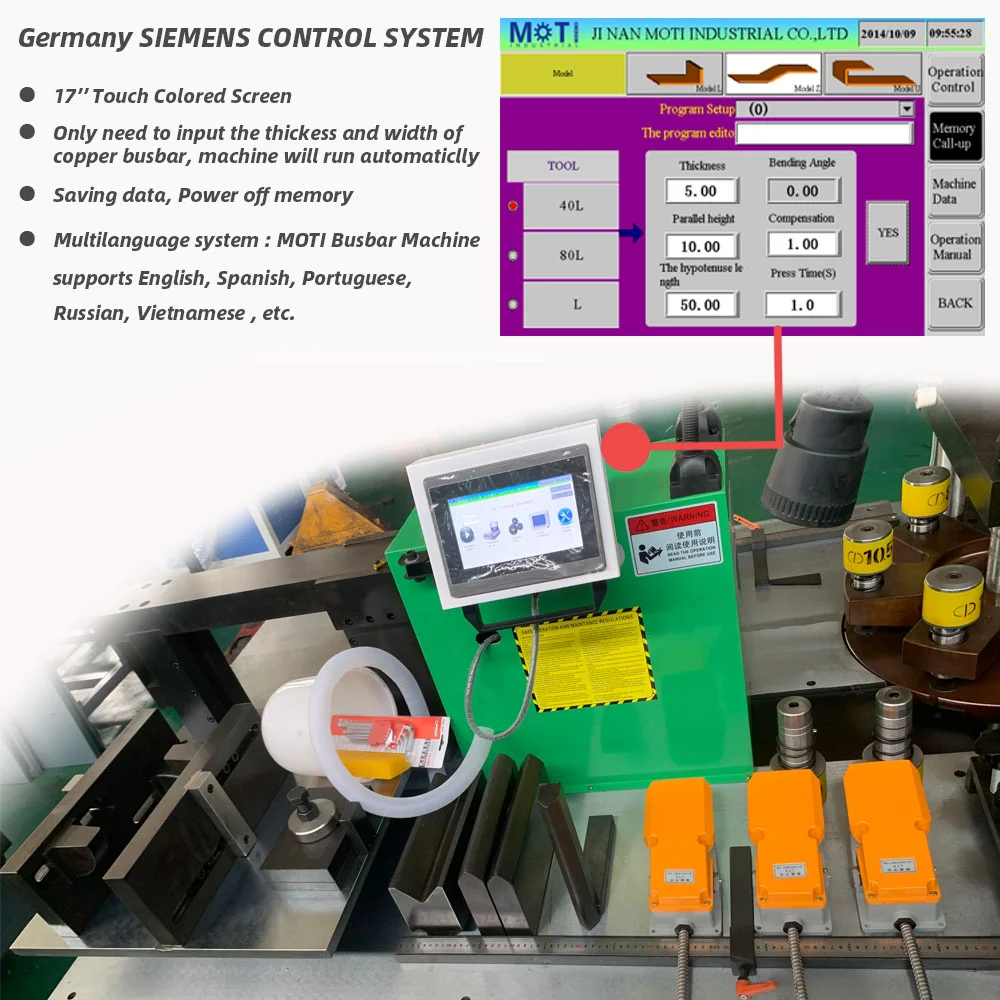

Germany SIEMENS CONTROL SYSTEM

#1. The whole MOTI Busbar Machine adopts Siemens PLC control, which is more stable and reliable than the traditional relay control

#2. SIEMENS PLC control, with an automatic stop function, can control the cutting station and punching station downtime,

compared with the traditional relay control is more stable and reliable.

#3. Saving data, power off memory

#4. Multilanguage system: MOTI Busbar Machine supports English, Spanish, Portuguese, Russian, Vietnamese, etc.