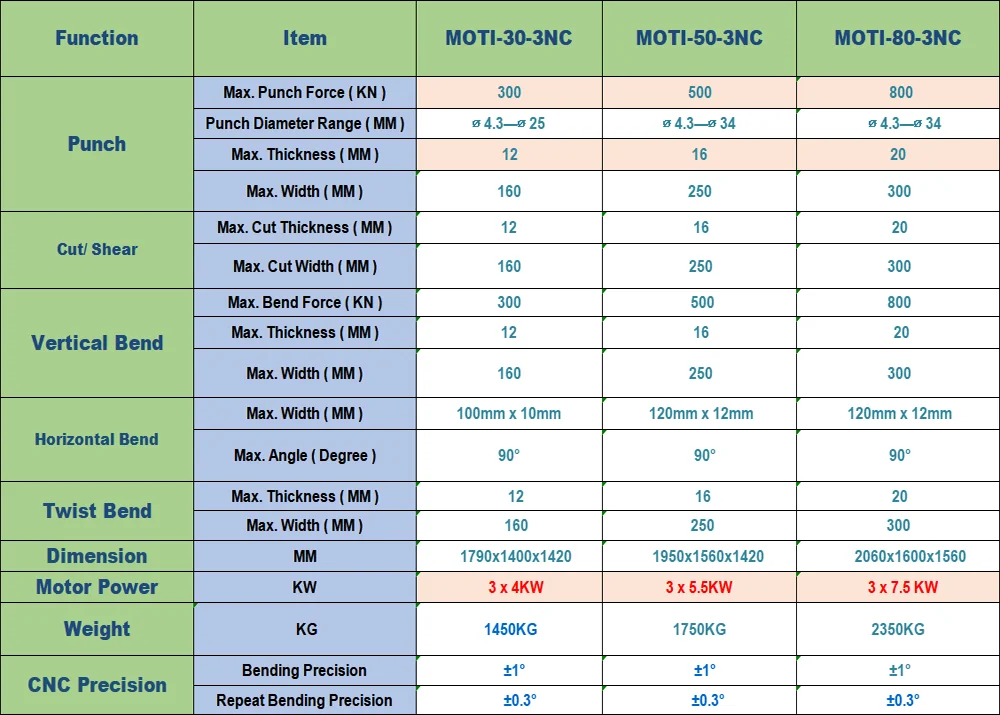

Powered by three separate hydraulic power packs

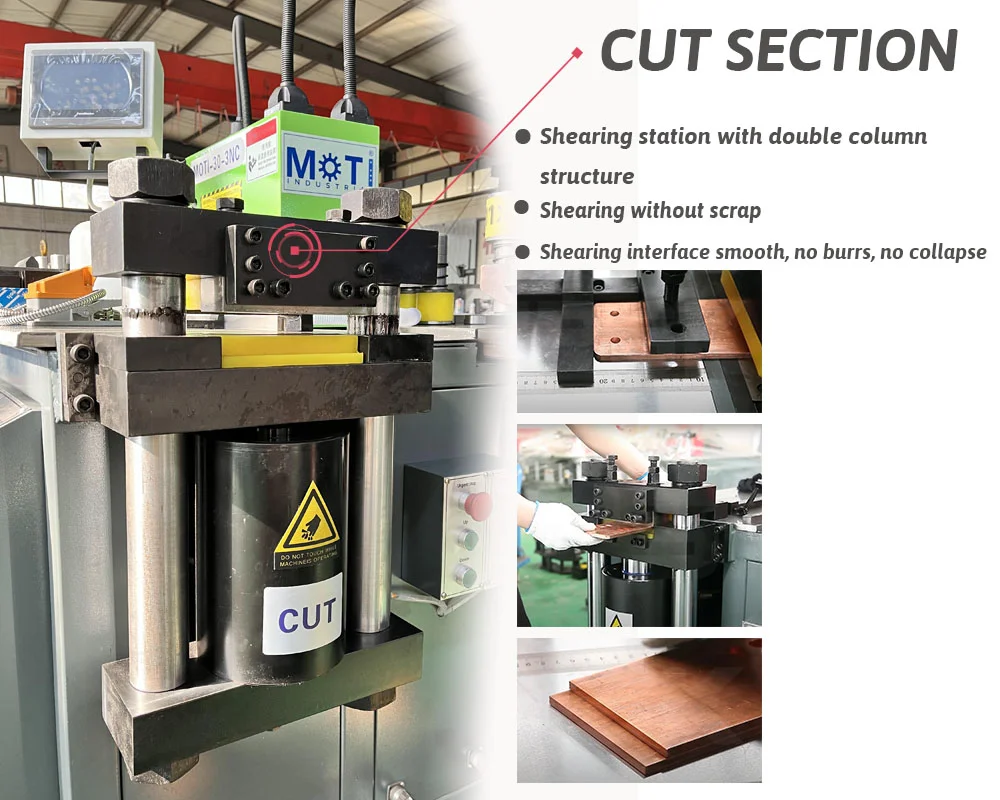

1. CUT--Double column shear structure

The shearing position adopts a double pillar structure with flat shears, no waste, no burrs, and no collapse feet.

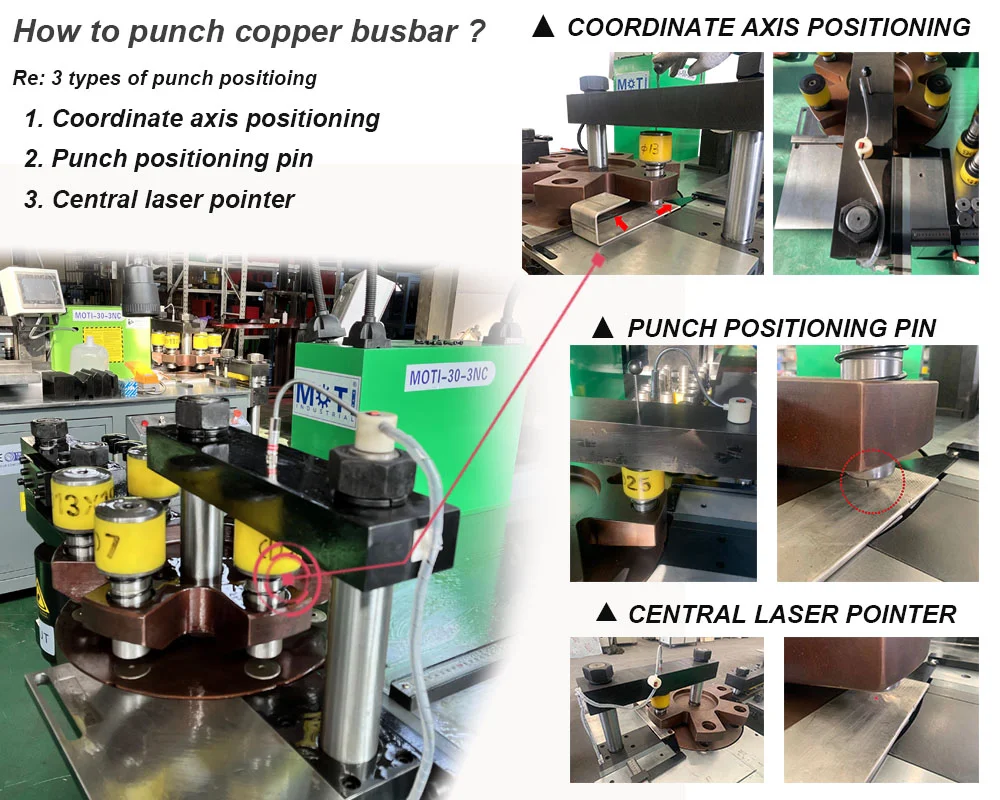

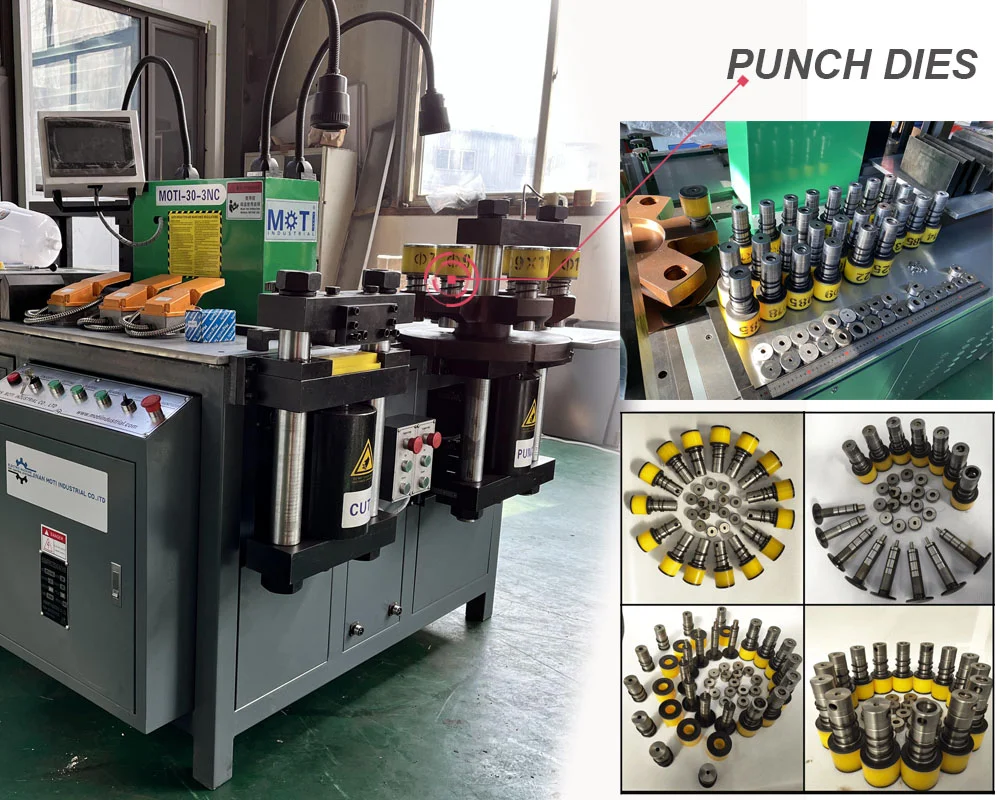

2. PUNCH--the united six-mode turnplate in tooth shape

(1) Three positioning methods: Laser pointer / Coordinate axis positioning / Positioning pin help to find the center of holes easily in the punche

(2) 6 sets of punching die to install turnplate. No need to change molds frequently

3. BEND-- Control by SIEMENS system

(1) Programmable meter systems cause high accuracy in bending

(2) Can finish Vertical Bending / Edge Bending ( Horizontal/Flat Bending ) / Z shaped Bending / U shaped Bending / Embossing / Twisted Bending, etc.

(3) Only need to input data, the machine will run automatically.

CUT SECTION of MOTI BUSBAR FABRICATIONMACHINE

#1. Cutting station with double column structure

#2. Shearing without scrap

#3. Shearing interface smooth, no burrs, no collapse

PUNCH SECTION of MOTI BUSBAR FABRICATION MACHINE

#1. Used the six molds position intergral turntable made of ductile iron materials

#2. Inproved punch dies concentricity

#3. Extend punch dies working life

#4. Saving frequency and time in replacing punching dies

How to punch copper busbar by MOTI BUSBAR MACHINE?

There're 3 types of punch positioning from MOTI BUSBAR MACHINE

#1. Coordinate axis positioning

#2. Punch positioning pin

#3. Central laser pointer

PUNCH DIES of MOTI BUSBAR FABRICATION MACHINE

#1. MOTI Busbar Machine can install 6 sets of different sizes of punch dies at one time

#2. Marked the size on the head and bottom of punch dies, easily identifiable to ensure consistent upper and lower mold dimensions

#3. Used the Cr12Mov mold steel as the original meterials, high hardness, excellent wear resistance and toughness

BEND SECTION of MOTI BUSBAR FABRICATION MACHINE

By changing different bending tools, MOTI Busbar Machine can do the Vertical Bending, Horizontal Bending, U sheped Bending,

Z shaped bending, Twisted Bending, embossing, etc.

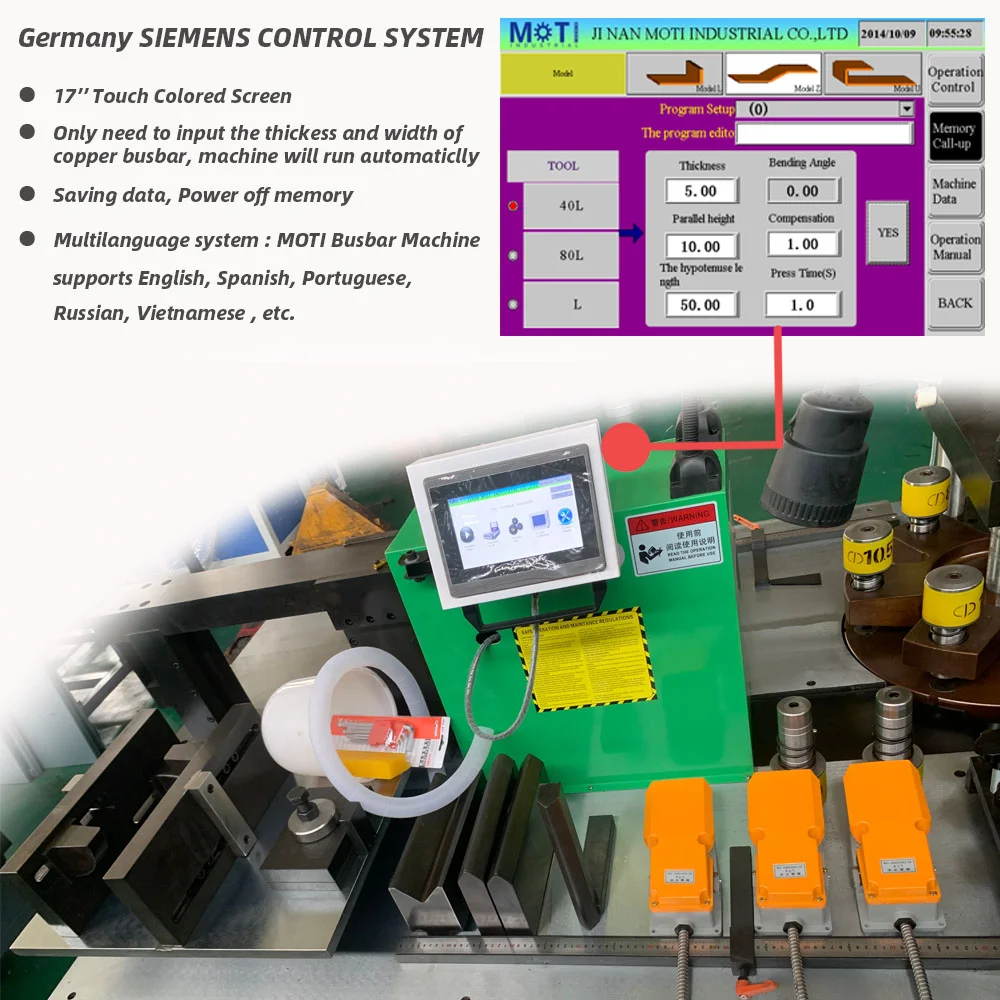

Germany SIEMENS CONTROL SYSTEM of MOTI BUSBAR FABRICATION MACHINE

#1. 17'' touch colored screen

#2. Only need to input the thickness and width of copper busbar, busbar machine will run automaticlly

#3. Saving data, power off memory

#4. Multilanguage system: MOTI Busbar Machine supports English, Spanish, Portuguese, Russian, Vietnamese, etc.

COPPER BUSBAR of MOTI FABRICATION MACHINE