Powered by three separate hydraulic power packs

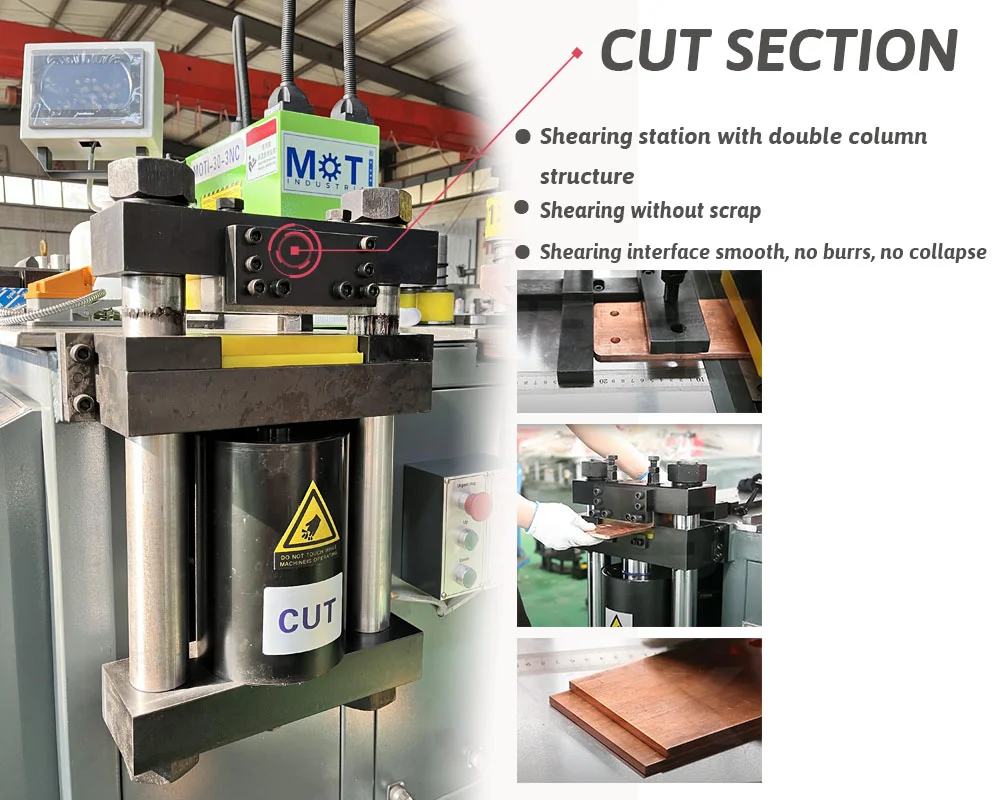

1. CUT--Double column shear structure

The shearing position adopts a double pillar structure with flat shears, no waste, no burrs, and no collapse feet.

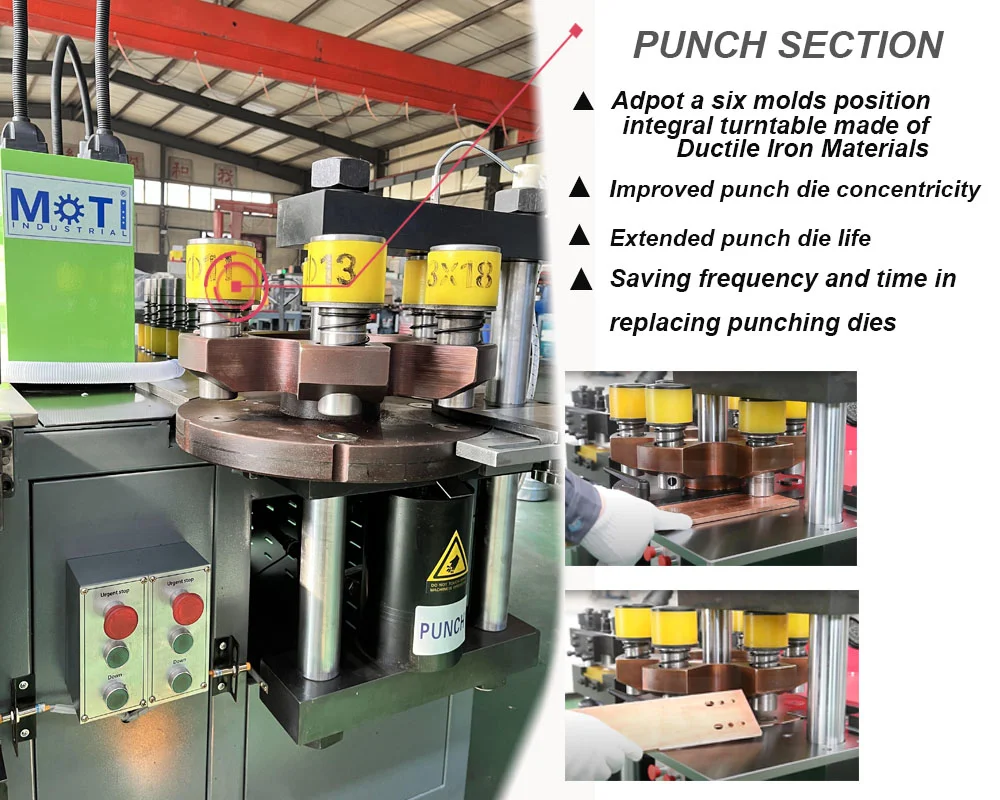

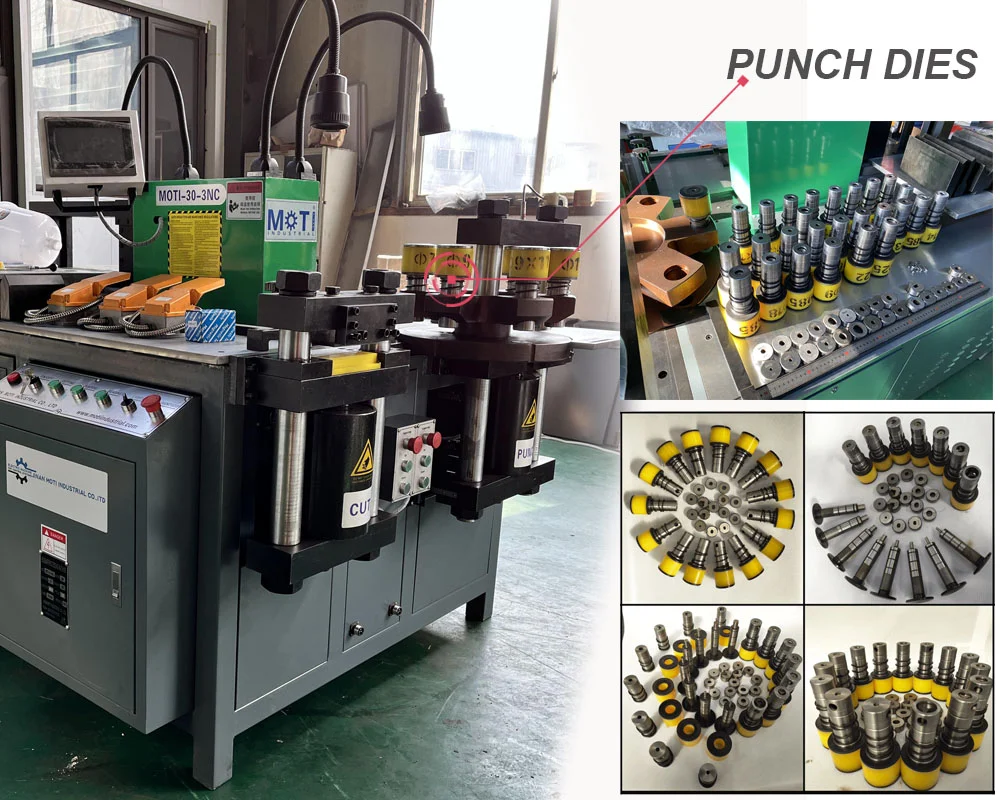

2. PUNCH--the united six-mode turnplate in tooth shape

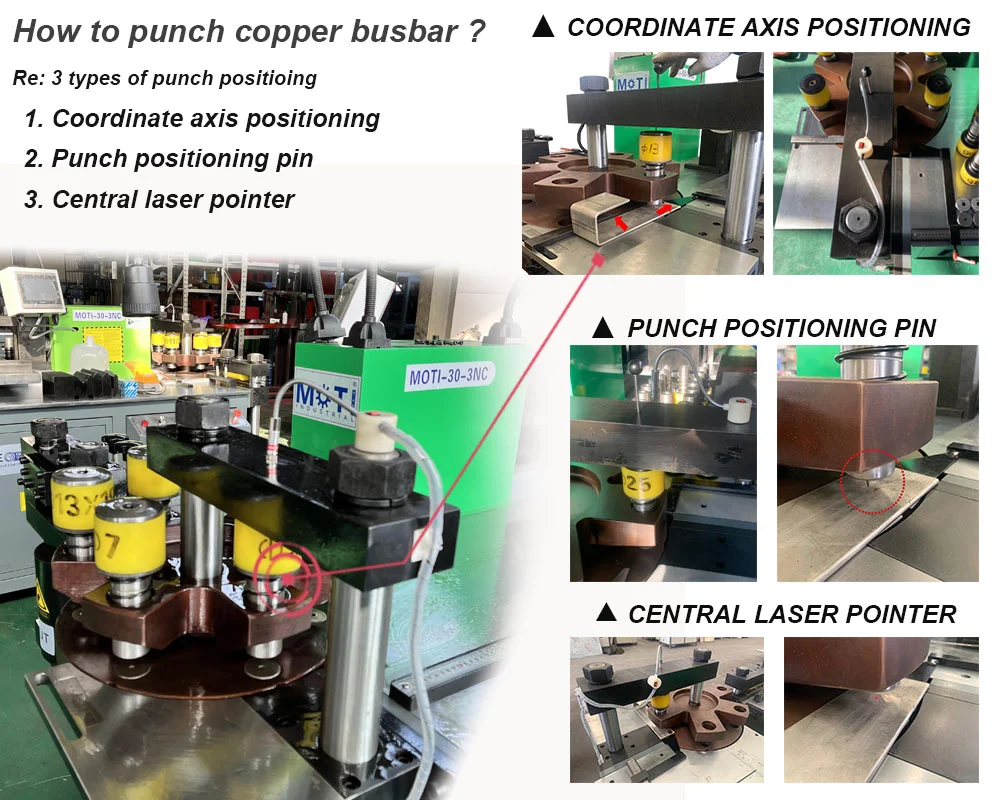

(1) Three positioning methods: Laser pointer / Coordinate axis positioning / Positioning pin help to find the center of holes easily in the punche

(2) 6 sets of punching die to install turnplate. No need to change molds frequently

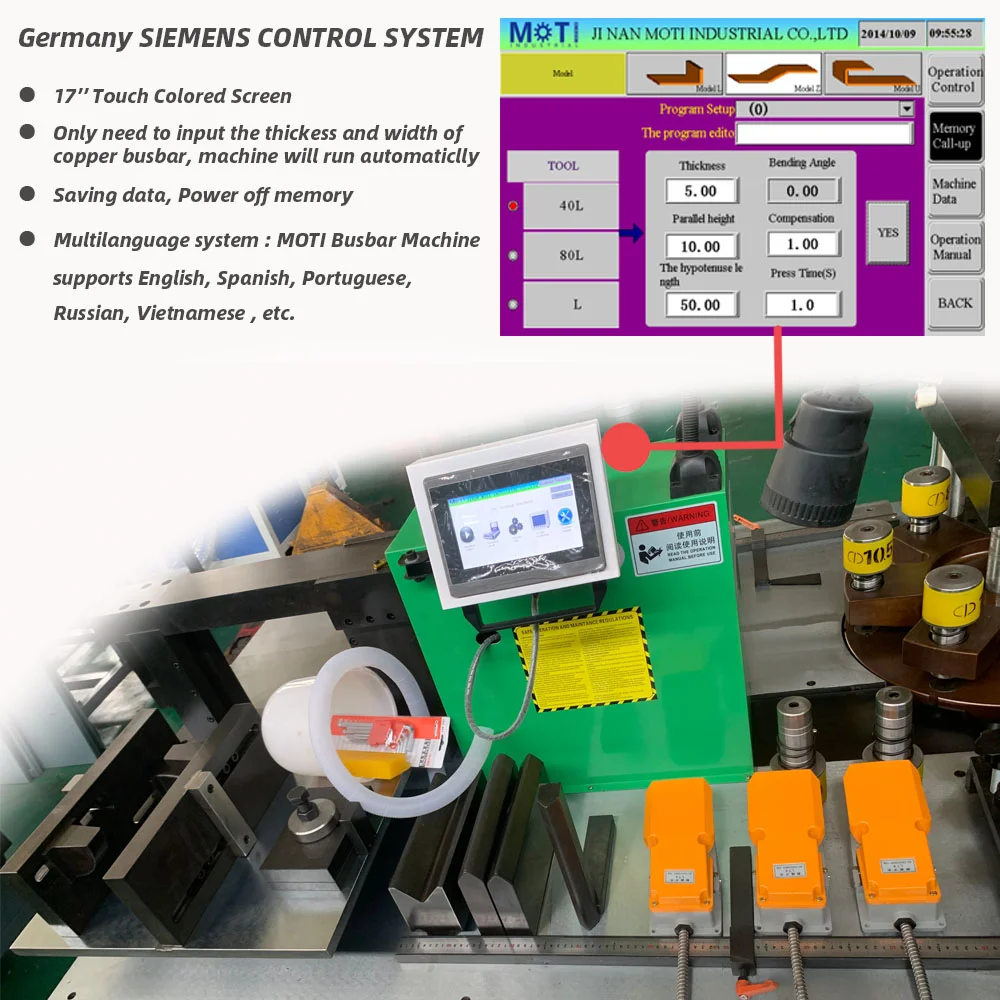

3. BEND-- Control by SIEMENS system

(1) Programmable meter systems cause high accuracy in bending

(2) Can finish Vertical Bending / Edge Bending ( Horizontal/Flat Bending ) / Z shaped Bending / U shaped Bending / Embossing / Twisted Bending, etc.

(3) Only need to input data, the machine will run automatically.

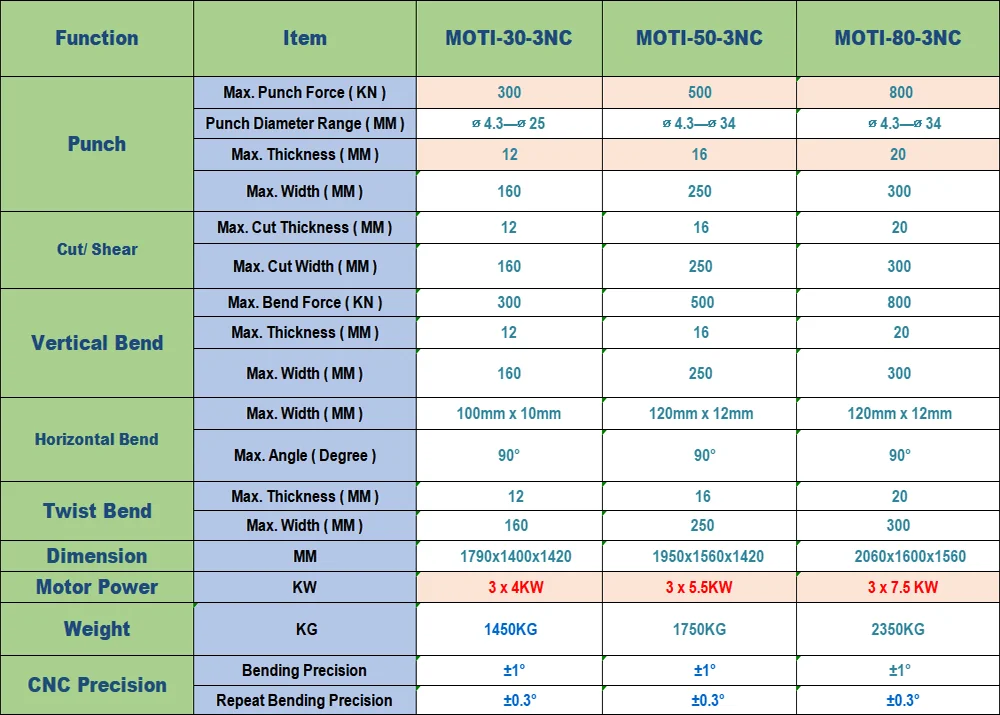

Technical Parameters of MOTI BUS BAR PROCESSING MACHINE

CUT SECTION of MOTI BUS BAR PROCESSING MACHINE

#1. Shearing station with double column structure

#2. Shearing without scrap

#3. Shearing interface smooth, no burrs, no collapse

PUNCH SECTION of MOTI Busbar Processing Machine

#1. Adopt a six molds position integral turntable made of ductile iron materials

#2. Improved punch dies concentricity

#3. Extend punch dies life

#4. Saving frequency and time in replacing punching dies

3 type of PUNCH POSITIONING

#1. Coordinate axis positioning

#2. Punch Positioning Pin

#3. Central Laser Pointer

BEND SECTION of MOTI BUS BAR PROCESSING MACHINE

By changing different bending tools, MOTI BUSBAR MACHINE can do Vertical Bending, Horizontal Bending,

U Shaped Bending, Z Shaped Bending, Twisted Bending, Embossing, etc.

Germany SIEMENS COCNTROL SYSTEM of MOTI BUS BAR PROCESSING MACHINE

#1. 17'' touch colored screen

#2. Only need to input the thickness and width of copper busbar, the machine will ran automaticlly

#3. Saving data, Power off memory

#4. Multilanguage system: MOTI Bus bar Machine supports ENGLISH, SPANISH, PORTUGUESE, RUSSIAN, VIETNAMESE, etc.

Copper Busbar Samples of MOTI BUSBAR MACHINE