How to calibrate the bending unit for Busbar Processing machine?

1. Why need to calibrate the bending unit for the Busbar Processing machine?

Before the Busbar Processing machine leaves the factory, we will set and debug the parameters of the Busbar Processing machine numerical control system.

However, due to the different purity and specifications of copper bars in various countries, when the customer bends after receiving the machine,

the angle of the finished bending workpiece will deviate from the set angle.

So, customers are required to perform mold calibration on the bending unit according to their own needs.

2. More details about how to calibrate the Busbar Processing Machine

We have made a detailed video explanation of how to calibrate the bending unit for the Busbar Processing machine, as well as further explanations with pictures and text. Details as follow,

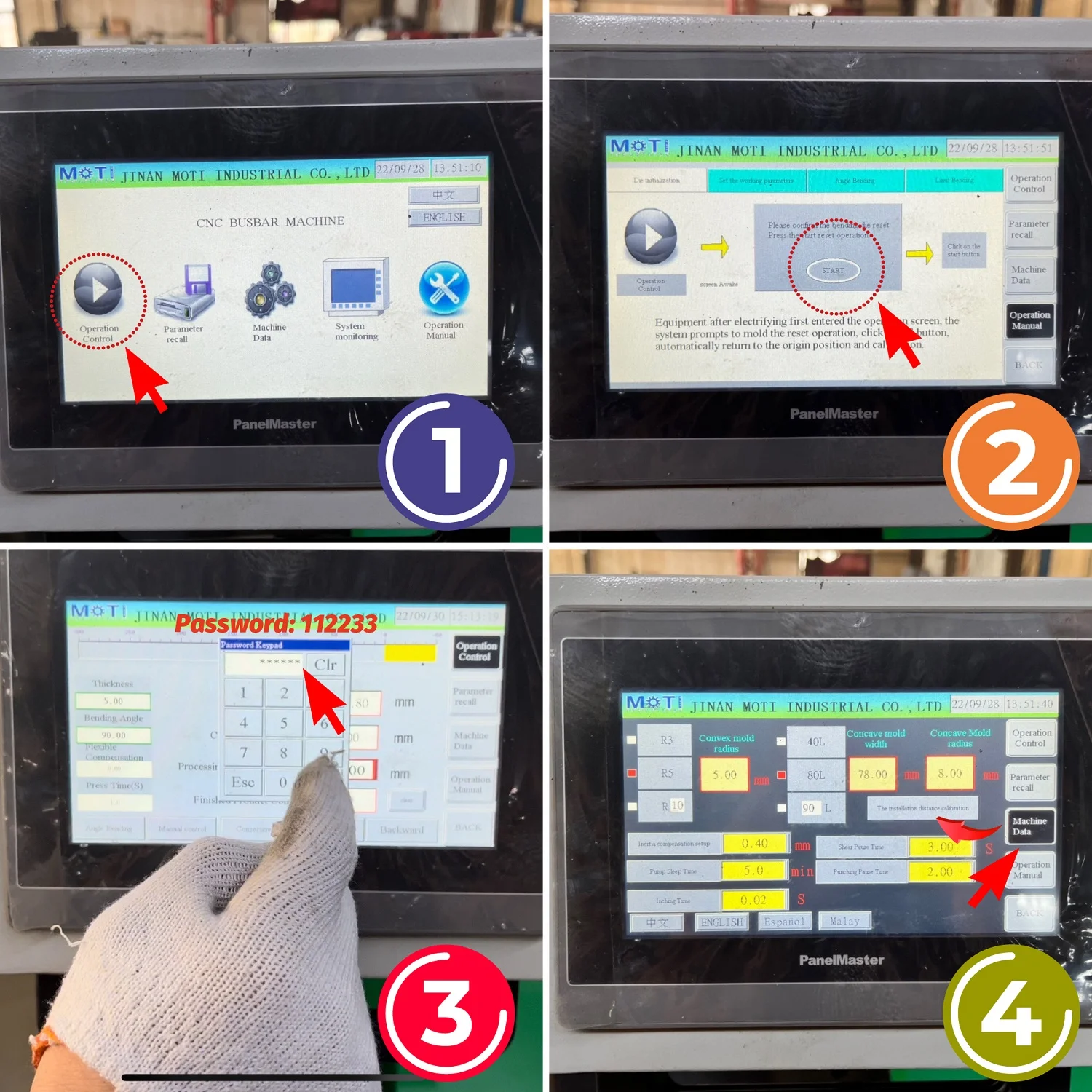

First, the preparation of the calibration

Follow the demonstration steps of the video, select the "Operation Control" button, jump to a new page, and click the "Start" button.

At this time, the bending unit of the machine will slowly return to its original position.

Next, click the "Machine Data" button on the screen, the protection function of the machine control system is activated, and a menu that requires to input"Password Keypad" pops up,

Input the password: 112233, click the "Ent" button, and the screen automatically jumps to the "Machine Data" page.

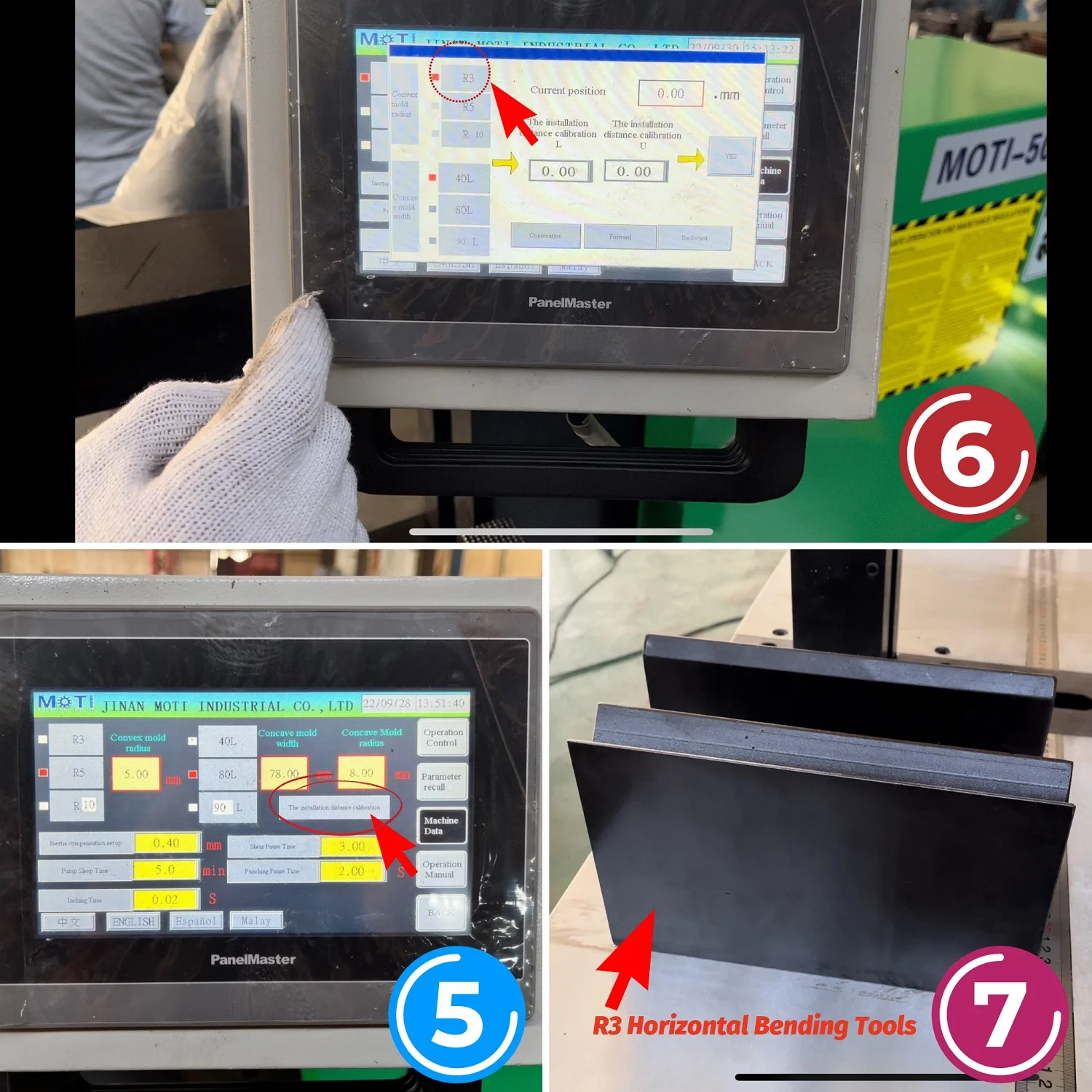

Click the "The installation distance calibration" button, select the corresponding bending die, and then install the die.

The machine model in the video is MOTI-50-3NC Busbar Processing Machine, the capacity of bending tools is as follows,

R3 is a Horizontal/flat bending die for processing thin copper bars, the processing range is within 1mm-5mm

R5 is a Horizontal/flat bending die for processing thick copper bars, the processing range is within 6mm-16mm

Second, the calibration operation starts

Take the embossing mold as a prop for the calibration, as shown in the video, and place the embossing mold between the two horizontal bending molds

Press and hold the "Forward" button, and the die slowly advances forward, when the die is firmly against the embossing die, stop pressing the "Forward" button.

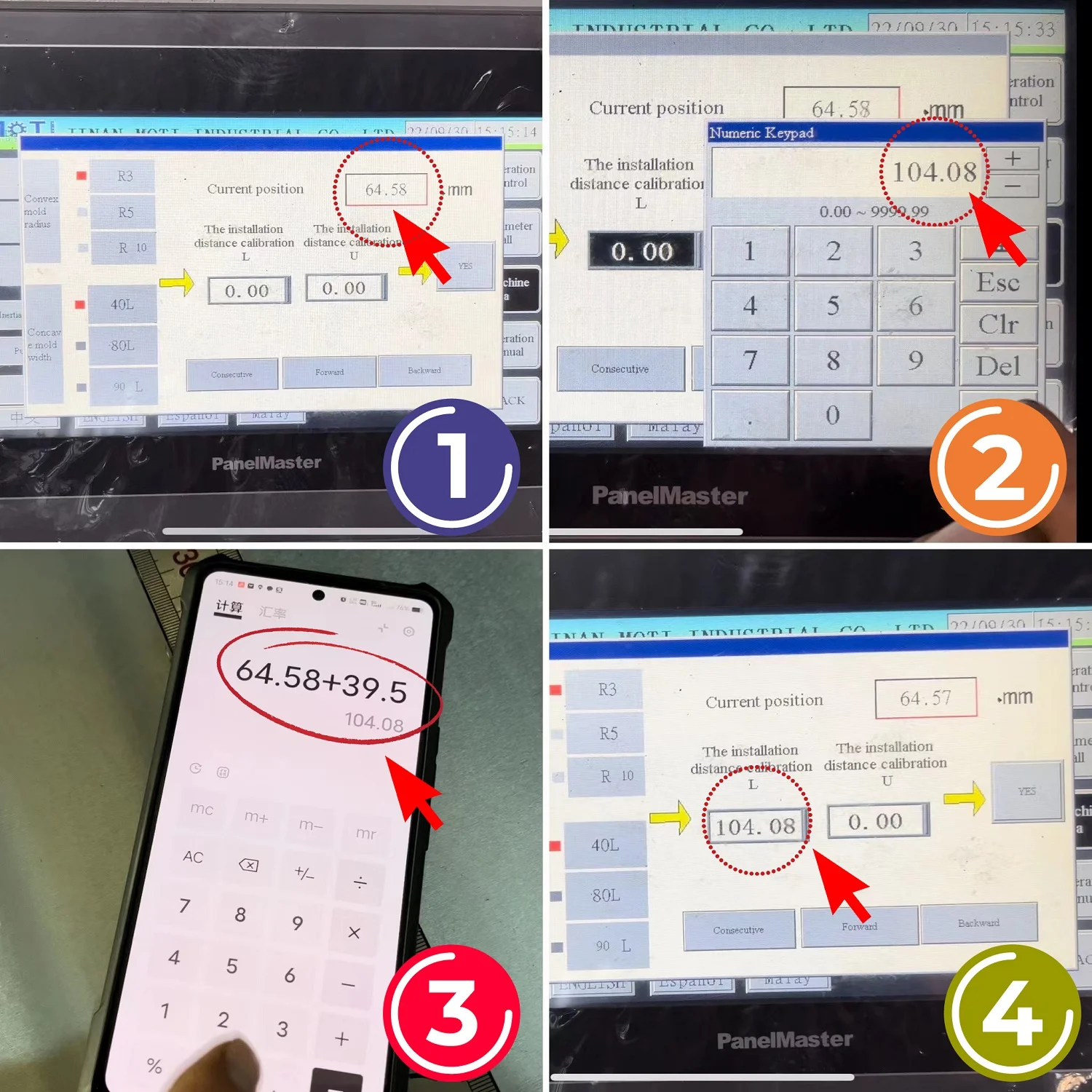

At this time, the value of "Current Position" on the screen is 64.58mm. The thickness of the embossing die is 39.5mm, which is a fixed value.

The installation distance calibration L = Current Position + Thickness of embossing die.

For example 64.58mm + 39.5mm=104.08mm ( Take out your phone and use the calculator to calculate the final value. )

Input the calculated value 104.08 into the system, as shown in the video. Click "Yes" to complete the calibration operation.

3. Why do you need to do the Flexible Compensation?

After calibrating the bending unit of the busbar machine, take 2 pieces of copper bars to test the accuracy of the bending angle.

After the bending operation, the bending result may be larger than the set bending angle.

So, it is necessary to adjust the bending accuracy of the bending through the "Flexible Compensation" function of the system.

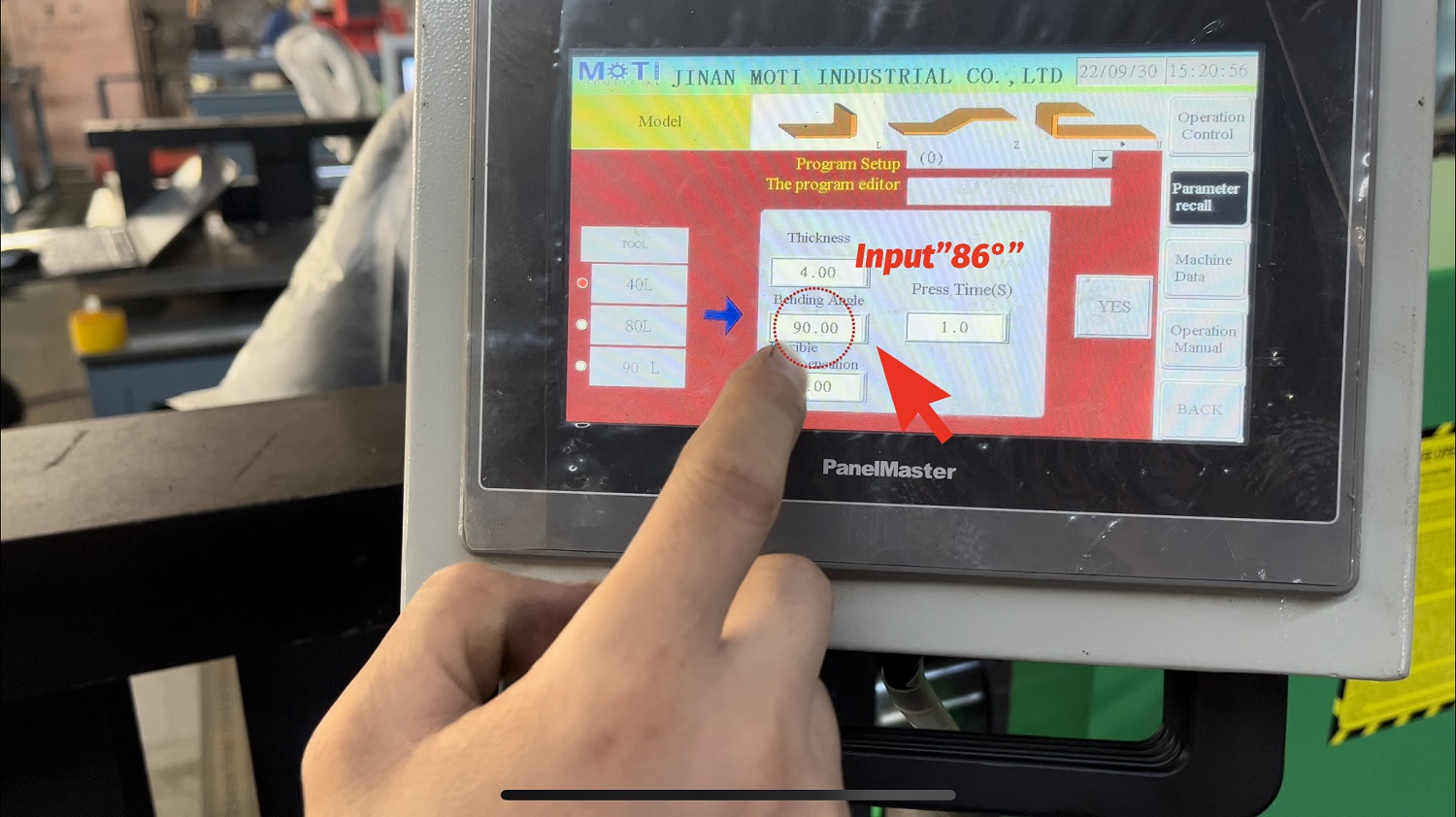

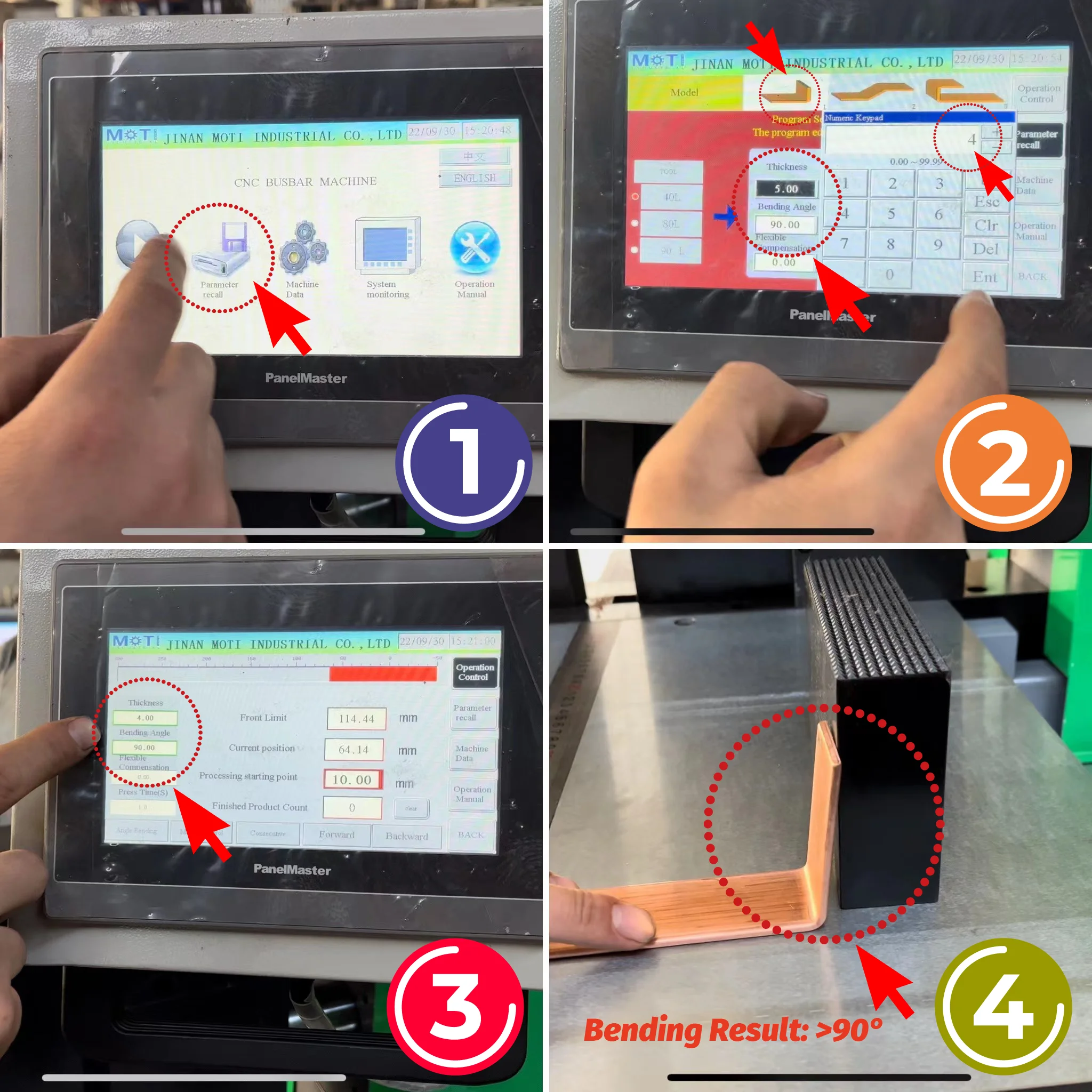

Click the"Parameter Recall" button, the control system will jump to a page.

#1. select and click the "L "picture button

#2. On the left side of the page, the corresponding bending tool model of "40L" is R3 Horizontal Bending Tools. Choose it.

#3. The thickness of the copper bar sample in the video is 4mm, and we want to test the bending angle is 90 degrees.

Input the corresponding value in the corresponding place. Then, click the "Yes" button.

#4. The operating interface will jump to the "Operation Control" page. Check and confirm the required value on the left side of page.

#5. Step on the foot switch or press the "Forward" button, and the machine completes the bending operation.

#6. Take out the bent copper bar, and measure or estimate the bending angle.

Obviously, the angle of the bent copper bar is greater than 90 degrees.

The next step of operating is Flexible Compensation

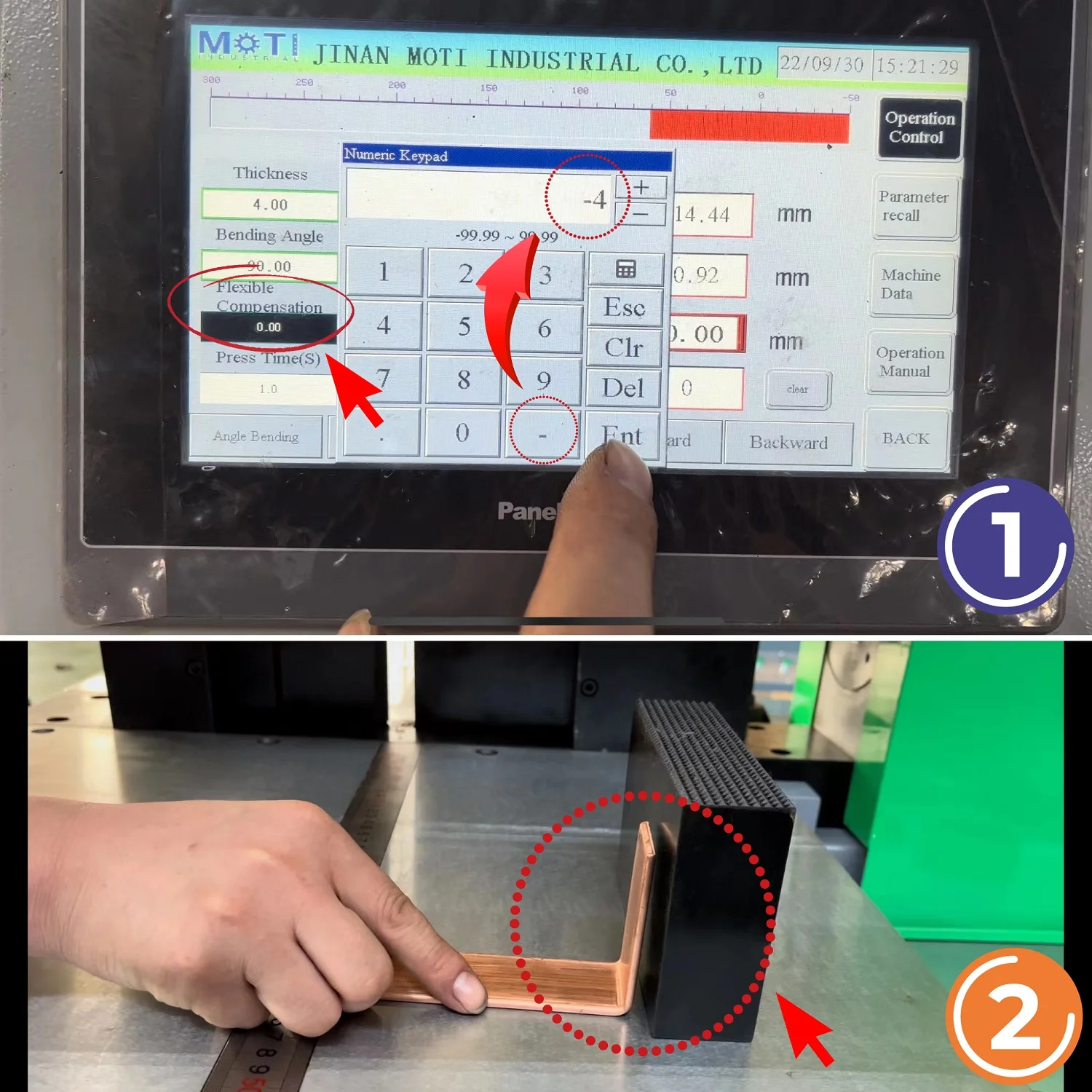

Click the "Operation Control" button to jump to the operating page, click the Flexible Compensation button then input"- 4 " and click "Fnt".

We estimate that the bending angle of the copper bar just now is 94 degrees, so we need to subtract the extra value.

For example,

The setting bending angle is 90 degrees, but the actual bending angle of the copper bar is 91 degrees.

We need to " - 1 " ( subtract one degree) by Flexible Compensation.

Put another 1 piece of copper busbar to the bending tools,

Step on the foot switch or press the "Forward" button, and the machine completes the bending operation.

Take out the bent copper bar, and measure the bending angle. You will get your required result.

Note:

1. Please do not use the already bent copper busbar to repeatedly test the bending angle, then do the Flexible Compensation.

Because then you will never get the bending angle you want.

2. If you need to process a copper bar with a fixed bending angle for a long time, you can directly set it to 86 degrees.