How to choose copper busbar in high and low voltage switchboards?

How to choose copper busbar in high-voltage and low-voltage switchboards?

Copper row, also known as copper bus bar or copper busbar, is a long conductor made of copper with a rectangular or chamfered (rounded) rectangular cross-section (now generally used rounded copper row to avoid tip discharge), which plays a role in conveying current and connecting electrical equipment in a circuit.

So, how to choose the copper busbar in high and low-voltage switchboards? How to calculate the load capacity and bending of copper busbar? More details as following,

Copper busbars are widely used in electrical equipment, especially in complete sets of power distribution devices; generally, copper busbars are used in U, V, W phase busbars and PE busbars in power distribution cabinets;

Copper busbars are generally marked with phase color letter signs or painted with phase color, U phase copper rows are painted with "yellow" color, V phase copper rows are painted with "green" color,

W phase copper coated with "red" color, PE busbar copper coated with "yellow and green" two-color answer.

Today we will learn the calculation of copper busbars!

1. The copper busbars of the load capacity calculation

First of all, we should understand that the installation of copper in the electric switchboards is divided into two forms, flat and vertical, vertical load capacity is slightly greater than the flat,

so the main bus bar of the distribution cabinet is mostly vertical form. There are also copper busbars, copper wire load capacity will also change with the ambient temperature,

where we use the most ambient temperature of 35 degrees Celsius. Under different ambient temperatures,

the load capacity derived from the table needs to be multiplied by the correction factor for different ambient temperatures,

the load capacity under different ambient temperatures, the higher the temperature, the lower the load capacity.

Based on experience, the summary is as follows.

Single copper busbar load capacity = width (mm) X thickness factor.

Double busbar load capacity = width (mm) * thickness factor x 1.5 (experience factor).

Copper and aluminum busbars can also be a square numbers, usually copper by 5-8A / square, aluminum by 3-5A / square.

Commonly used is a copper busbar of the load capacity calculation method.

40 ℃ when the copper row load flow = row width x thickness coefficient (thickness + 8).

Row width (mm); thickness coefficient is: 20 when the female row is 12 thick; 18 when it is 10 thick; in order: [12-20, 10-18, 8-16, 6-14, 5-13, 4-12].

Double-layer copper row [40℃] = (1.56-1.58) x single-layer copper row [40℃] (according to the size of the cross section).

3-layer copper row [40°C] = 2xsingle-layer copper row.

4 layers of copper row [40 ℃] = single copper row [40 ℃] x 2.45 (not recommended for this type of choice, it is best to use a shaped bus bar instead).

For example, to find TMY100x10 load capacity as follows

Single-layer: 100x188=1800(A) [check the manual for 1860A].

Double layer: 2 (TMY100x10) the load capacity is: 1860 x 1.58 = 2940 (A); [check the manual for 2942A].

Three layers: 3(TMY100x10): 1860x2=3720(A) [check the manual for 3780A].

All the above calculations are accurate to be quite close to the manual data

2, The calculation method of copper bending

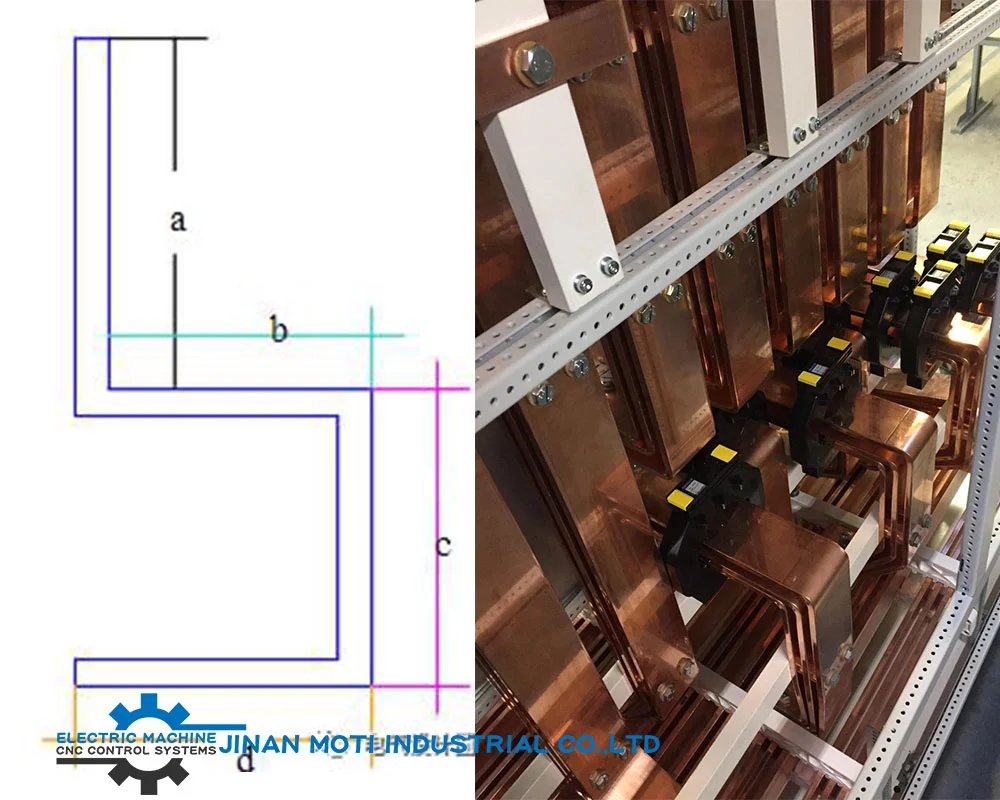

(1) flat bending (right-angle bending) outside the algorithm

The above figure has the following material lengths

Total length = a + (material thickness) + b + (material thickness) + c + d - coefficient x number of right angle bend

Note: Add material length all according to the additional

Coefficients are basically as follows.

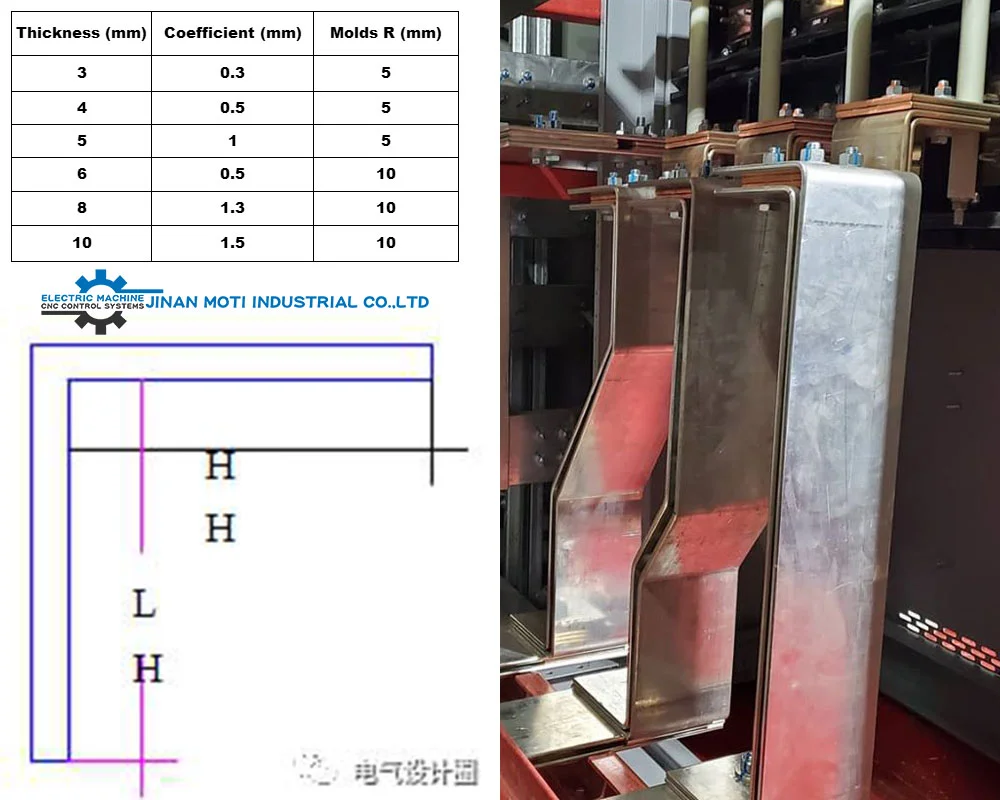

(2) flat bend (right angle bend) within the algorithm

(3) Example

When the material thickness is 3mm, the total length= L+0.3+H+0.3

When the material thickness is 10mm, the total length= L+1.5+H+1.5

Note: Each corner is added twice

3, The choice of copper busbars in the high-voltage switchboards

High-voltage switchboards copper busbars cross-section selection needs to meet two requirements.

(1) to meet the rated current

(2) to meet the short-time withstand current

The first can be calculated through the load capacity, then the second need to write down the formula in GB3906 [Appendix D]: S = I/a√(t/△θ) where: I - rated short-term withstand current; a - material coefficient, copper 13, aluminum 8.5; t - rated short-circuit duration; △θ - temperature rise (K). For bare conductor generally take 180K, for 4S duration take 215K.

Then.

25KA/4S system copper busbar minimum cross-sectional area S = (25/13)*√4/215 = 260 mm2.

31.5KA/4S system copper busbar minimum cross-sectional area S=(31.5/13)*√4/215=330 mm2.

40KA/4S system copper busbar minimum cross-sectional area S=(40/13)*√4/215=420 mm2.

63KA/4S system copper busbar minimum cross-sectional area S=(63/13)*√4/215=660 mm2.

80KA/4S system copper busbar minimum cross-sectional area S=(80/13)*√4/215=840 mm2.

The above two conditions accounting for the copper row cross-section needs to be selected as the maximum.

For example, the current parameters given by the design institute in a circuit are: rated current 630A, short-time withstand current 31.5KA,

then the rated current 630A should use TMY-40 x 6, the short-time withstand current 31.5KA should use

TMY-60 x 6 (31.5KA/4S copper busbar minimum cross-sectional area of 330 mm2 through the above table),

TMY-60 x 6 cross-sectional area of 360 mm2. 60 x 6 cross section of 360 mm2 is greater than the minimum cross-sectional area of 330 mm2 in the above table.

According to the maximum value of the two conditions, the busbar with rated current of 630A and short-time withstand current of 31.5KA should be selected as TMY-60 x 6.