What is busbar machine?

What is busbar machine?

Busbar processing machine has three processing units: shearing, punching and bending.

The main function is to process different specifications of copper and aluminium busbars, which can be easily and quickly processed in different ways.

Such as shearing, punching (round and waist-shaped holes), bending flat, standing bending, embossing, flattening, twisting twist and pressing cable joints on copper and aluminium busbars with only the corresponding processing units.

Widely used in high and low voltage switchgear, substations, busbars, bridges, electrical switches, communication equipment, household appliances, shipbuilding, office automation equipment, lift manufacturing, chassis and cabinet manufacturing and other electrical complete manufacturing industries.

Busbar processing machine is designed to improve the efficiency of copper processing and to ensure the safety of the work requirements of the power supporting equipment.

It is most suitable for the production of large electrical control boxes and the construction site of transmission and distribution projects.

Main features of Busbar Processing Machine

1, Shearing unit adopts universal double-knife shearing, with flat and burr-free cutting edge.

2, Punching unit adopts high precision five-arm punching die holder, which prolongs the service life of the die.

Clearer line of sight for operation, easier and quicker to use, no need to change moulds, improved production efficiency

3, Hanging hook open bending station Simple and convenient operation Can process special back shape Small bending, embossing, vertical bending, etc.

4, bending unit using horizontal processing, in the processing of more secure and convenient can complete a minimum of 3.5MM U-bend.

5, the machine's three work stations can work simultaneously, without affecting each other, greatly improving efficiency.

6, the working stroke of each processing unit can be easily adjusted to reduce processing time and improve production efficiency.

7,The hydraulic oil tank is welded with thick steel plate and treated with phosphate, so that the hydraulic oil will not deteriorate in long-term use.

8, hydraulic hose using the national standard A connection, that is, durable and convenient maintenance.

9, CNC bending using two ways :

(1)Traditional bending directly input angle and thickness.

(2)Triangle function bending directly input right angle two sides, the length of the beveled side automatically calculated without manual open calculation angle

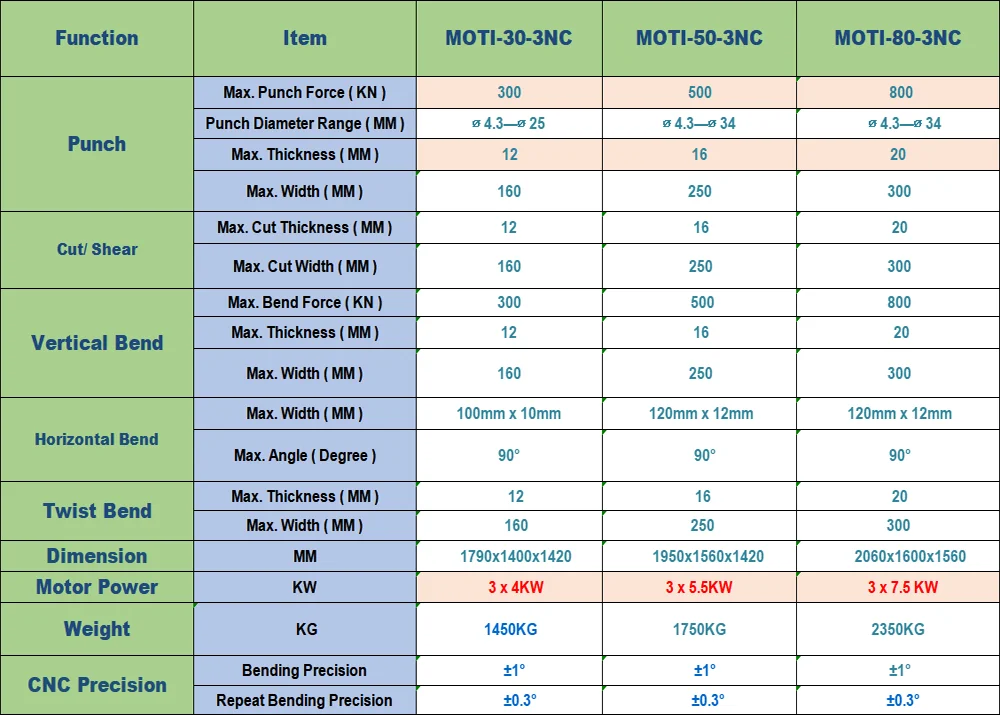

Technical Specifications of Busbar Processing Machine

Safe operation of Busbar Processing Machine

Before operation

1, the first time before the machine must be filled with oil to the tank to avoid damage to the oil pump.

2, You must read this instruction manual carefully and be familiar with the structure, performance and operation of the machine.

3, Do not operate with a scarf or wear clothes such as an overcoat.

4, Work in the correct way in order to stop and get rid of the danger as soon as possible in case of malfunction.

5, If the ambient temperature is below 0°C, the machine should be turned on for a few minutes of air rotation before working.

In operation

1, Installation, commissioning (mould alignment, blade gap adjustment) or dismantling of the mould must be carried out by personnel familiar with the machine in accordance with the prescribed protocols.

2, Do not put your hand or part of your body between the upper and lower moulds (blades) when the machine is in normal operation, to avoid accidents.

3, Do not put all miscellaneous objects and tools on the working table to avoid rolling into the mould or the blade and causing accidents.

4, Since the machine can be operated by more than one person, a person must be in charge of directing the production.

5, must be based on the thickness of the copper row (or aluminium row) to choose a good shear blade and die clearance and bending radius.

6, in the replacement of the mould must be stopped to avoid danger.

7, in operation, holding the workpiece waiting for the slider down the line must be careful.

8, The sharpness of the blade and die edge should be checked regularly. If the edge is found to be dull, it should be resharpened or replaced in time.

9, Keep the oil clean and the oil circuit smooth, and lubricate the moving parts of each unit every shift.

10, Electrical and hydraulic components must be flexible and correctly positioned, and must be stopped immediately for inspection if irregularities are found.

After operation

After operation, the machine must be safely shut down in the following order.

(1) Turn off each unit work button.

(2) Switch off the power switch on the operating panel.

(3) Switch off the main circuit air switch.

(4) Switch off the workshop power switch

Application areas of the busbar machine

Busbar machines are mainly used in the high and low voltage switchgear and transformer manufacturing industries for processing copper and aluminium busbars of various specifications. As long as the corresponding processing unit can be bus bar punching, shearing, folding processing, high production efficiency.

The busbar machine is easy to use and has a significantly higher production efficiency than traditional busbar processing equipment. The working stroke of each unit can be easily adjusted, reducing the processing aid time and increasing production efficiency. A variety of processing functions can be achieved by changing the moulds, such as embossing, flattening, pressing cable joints and button twist. The machine is equipped with castors, which can be easily moved by adjusting the four feet.

hydraulic busbar machine, busbar bending machine, 3 in 1 busbar machine, busbar manufacturing machine, busbar bender machine, busbar processing machine

busbar cutting machine, CNC busbar bending machine, Portable busbar bending machine, hydraulic busbar bending machine, Namsung busbar machine, copper busbar bending machine,

busbar bending and punching machine, busbar punching machine