Important Points of Busbar Punching Machine

Key Points of Punching Work for MOTI Busbar Processing Machine

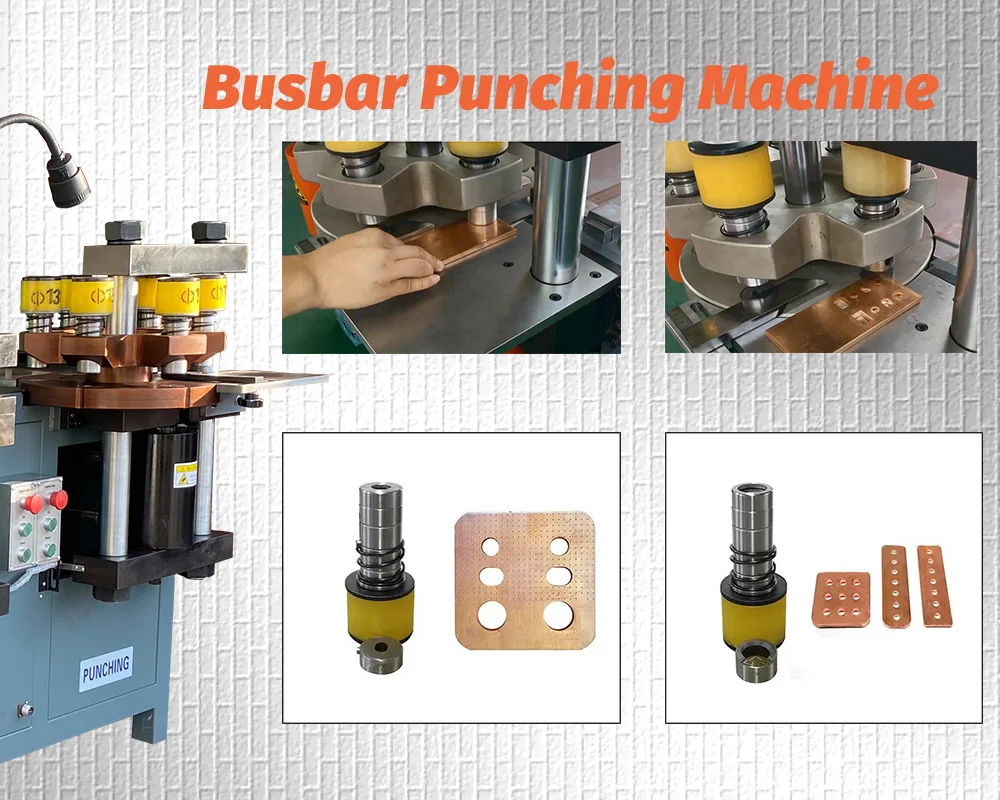

(1) When installing the mold, pay attention to the size of the upper and lower molds must match.

(2) When installing the waist hole or special-shaped hole, pay attention to the direction of the upper and lower mold positioning keys to be consistent.

(3) The die that needs to be punched must be positioned under the upper beam of the punching hole before it can work.

(4) After the X-axis and Y-axis dimensions of the positioning stopper are determined, the copper bar must be close to the stopper (to reduce the error).

(5) Regularly check whether the position of the travel switch is loose, and the upper die entry modulus should be greater than 0.1 and less than 1mm.

KEYWORDS for BUSBAR MACHINE

3 in 1 busbar machine busbar punching machine busbar bending machine busbar processing machine Busbar processing machine

Busbar machine ehrt punching machine busbar forming busbar machine manufacturers busbar machine price busbar machine korea

busbar machine china busbar machine hs code busbar machine manual busbar machine for sale 3 in 1 busbar machine

ehrt busbar machine namsung busbar machine alfra busbar machine moti busbar machine boschert busbar machine woojin busbar machine

cnc busbar machine jingpeng busbar machine hydraulic busbar machine busbar bending machine busbar punching machine

busbar cutting machine busbar processing machine busbar cutting punching and bending machine busbar bending machine manual

busbar bender machine busbar fabrication machine busbar bending and punching machine busbar bending machine manufacturer in ahmedabad