How to use a Hydraulic Busbar Punching Machine

The operation of Busbar Punching Machine

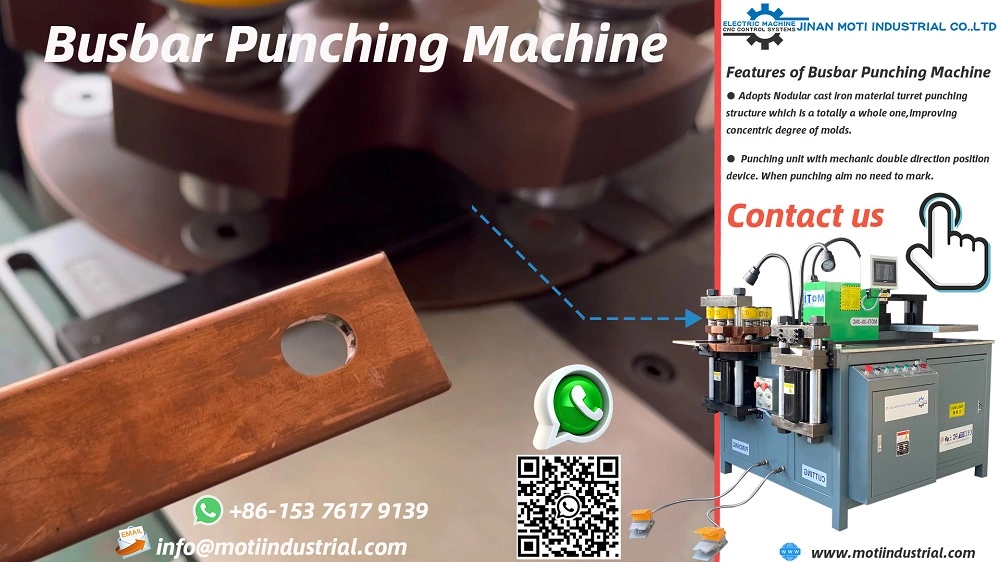

MOTI INDUSTRIAL: CNC Busbar Cutting Bending & Punching Machine Manufacturer.

At MOTI INDUSTRIAL, we provide business of all size with the latest in copper busbar, aluminum busbar and steel bar

fabrication equipment.

MOTI Busbar Punching Machine provides fast, highly-accurate punching of copper bus bar and other flat bar materials.

Features of MOTI Hydraulic Busbar Punching Machine

Punch copper busbar, aluminum busbar and steel bar

Adpots Nodular cast iron material turret punching structure which is a totally a whole one,

improving concentric degree of molds.

For material ranging from 4.3mm ( ) to 34mm ( ) thick

Create circular (round) holes, slots (oval) hole, chamfers, radiuses and more, in a range of size

MOTI Hydraulic Busbar Punching Machine with mechanic double direction position device. When punching aim no need to mark.

There're 3 methods of punching positioning: #1. Coordinate Setting #2. Punching Positioning Pin #3. Laser Positioning

On the internet, seldom showing the videos of Aluminum Busbar Punching.

Survey on India customers always like using the aluminum busbar to install the switchboars, electric control panels, etc.

The below video is about punching the aluminum busbar,

About the punching round hole, oval hole and chamfering copper busbar, please check the below video,

MOTI Busbar Machine has Bending, Punching and Cutting three functions in one machine ( 3 in 1 )

If you want to check more details about this hydraulic busbar punching machine, check the below links,

https://www.motiindustrial.com/images/cnc_busbar_processing_machine_3_in_1_/113.html