What is the busbar bending machine?

What is the busbar bending machine?

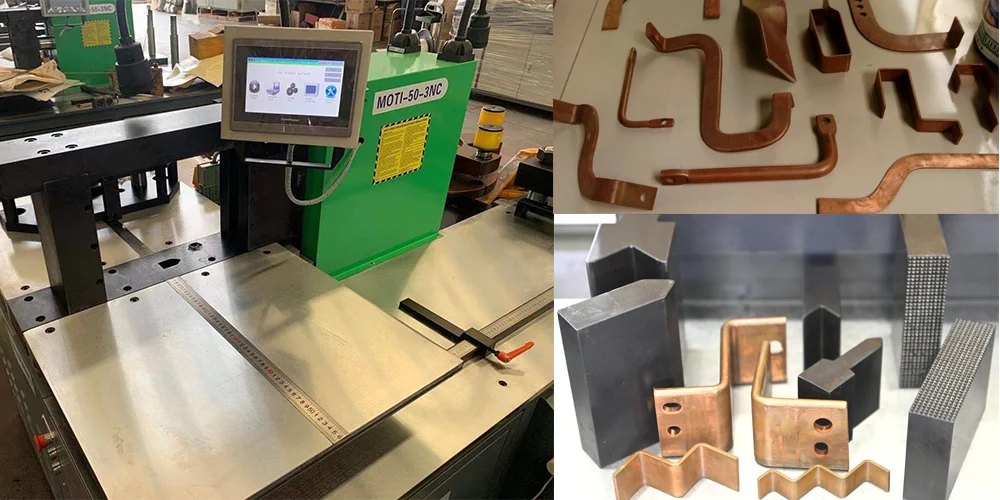

The multi-functional busbar bending machine is mainly used in the high and low voltage switchgear (switchboard / electric control panels / power control distribution),

power transmission and distribution complete electrical and transformer manufacturing industry for processing various specifications of copper and aluminium busbar.

The multi-functional busbar bending machine is equipped with three work units for punching, shearing and bending, which can be used for punching, shearing and

bending copper busbars separately or simultaneously by means of a foot switch or a manual switch.

By quickly changing the die and can complete the processing of horizontal / flat bending, vertical bending, punching round holes, oblong holes, square holes, embossing,

pipe bending, pressing wire nose, bending copper bars and other processes, easy to use, high production efficiency.

The bending unit of CNC bus bar bending machine using carbon steel plate welding structure, and by the high temperature tempering effect, the surface of the shot blasting to eliminate welding stress, remove the oxidation skin treatment, the equipment structure is solid, solid material, impact resistance, long-lasting use of non-deformation. The equipment has a beautiful and generous appearance and fine workmanship.

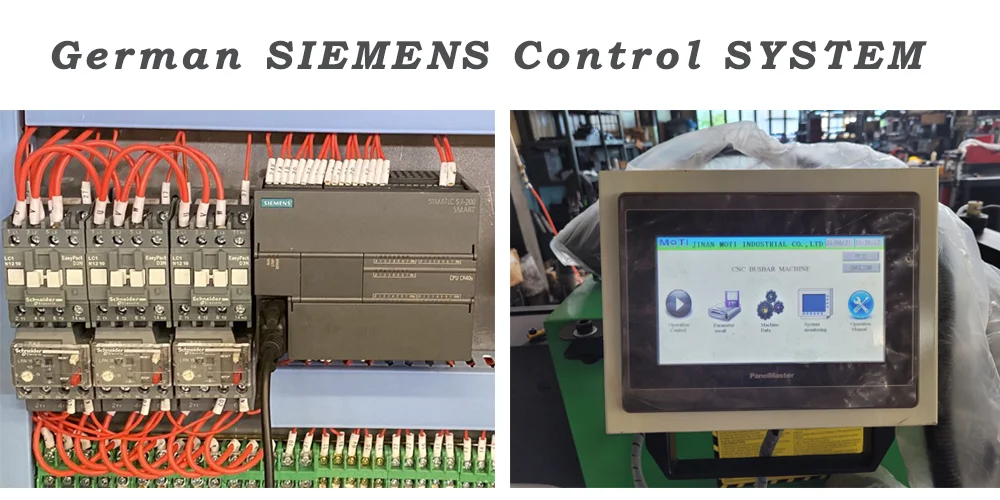

The bending unit of the CNC copper bus bar bending machine is a computer-controlled bus bar bending machine, which is controlled by the German Siemens CNC control system and manually assisted by the feeder to complete various bending actions. Through the selection of different bending moulds can complete the copper bus bar plane bending, lateral bending and other processing technology.

SIEMENS Control SYSTEM

The bending electrical part of the CNC-controlled multi-functional busbar bending machine uses the German Siemens CNC system.

(1) SAVE DATA Function.

The CNC system has a memory function. The worders can save more than one handred processed data into the control system.

(2) Automatic Operation

The workers can input the system according to the thickness of the processed copper busbar and the required bending angle,

The German Siemens CNC operating system (PLC system) automatically generates data, the busbar bending machine will bend processing automaticlly.

The use of this machine is highly productive and easy to process. Data from the workpiece can be added to the system at any time and can be adjusted for reuse.

(3) Color Touch Screen

The display screen adopts a 7-inch colour touch screen display mode and has a password protection function, so that inappropriate data can be modified.

If the works use a non-standard workpiece, the data can also be processed according to the requirements of the non-standard workpiece, which is very convenient to operate.

By adjusting the inductive switch of the working cylinder to control the stroke distance working pointer corresponding to different scale scales, the corresponding bending angle can be completed.

hydraulic busbar machine, busbar bending machine, 3 in 1 busbar machine, busbar manufacturing machine, busbar bender machine, busbar processing machine

busbar cutting machine, CNC busbar bending machine, Portable busbar bending machine, hydraulic busbar bending machine, Namsung busbar machine, copper busbar bending machine,

busbar bending and punching machine, busbar punching machine