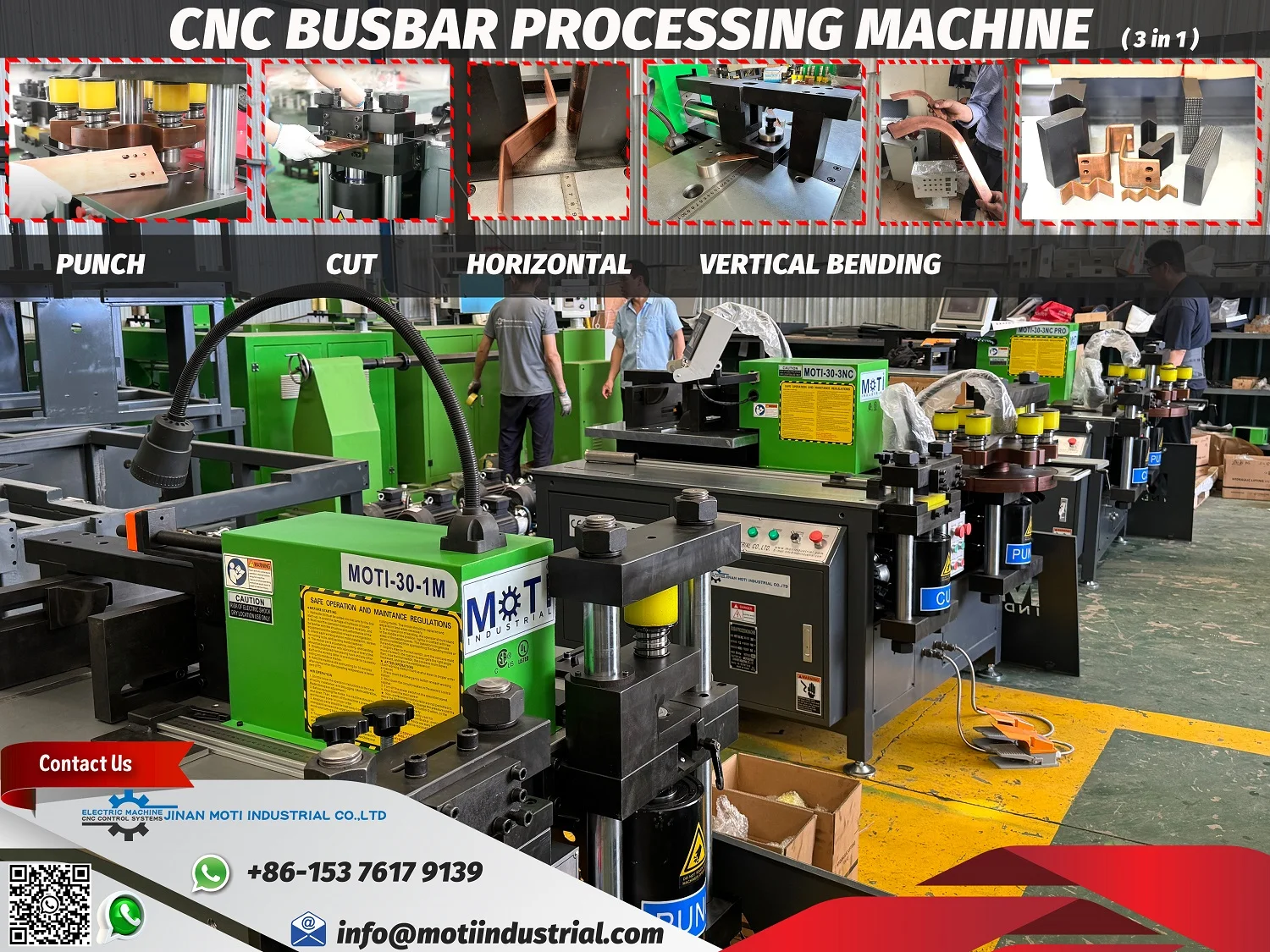

Automatic CNC Servo Copper Busbar Machine MOTI-30-3NC PRO To USA

The MOTI-30-3NC PRO multi-functional CNC busbar processing machine is equipped with four servo automatic measurement modes, ensuring that when punching, shearing, and bending copper busbars with capacity maximum size of 12x160mm,

the copper busbar machine can automatically move to the corresponding position according to pre-set parameters to perform the punching, shearing, and bending operations.

This greatly saves time, improves work efficiency, and ensures the accuracy of copper busbar processing.

1. The technical parameter of automatic CNC servo busbar processing machine MOTI-30-3NC PRO

If you want to know more detailed information about the MOTI-30-3NC PRO busbar processing machine, check the link below,

2. Video of CNC busbar processing machine MOTI-30-3NC PRO preparation before shipment

Before shipping, the CNC busbar processing machine undergoes preparation work, debugging, and performance testing.

This process is recorded on video and documented with photos, which are then sent to the customer for verification. Following this, the packaging process begins.

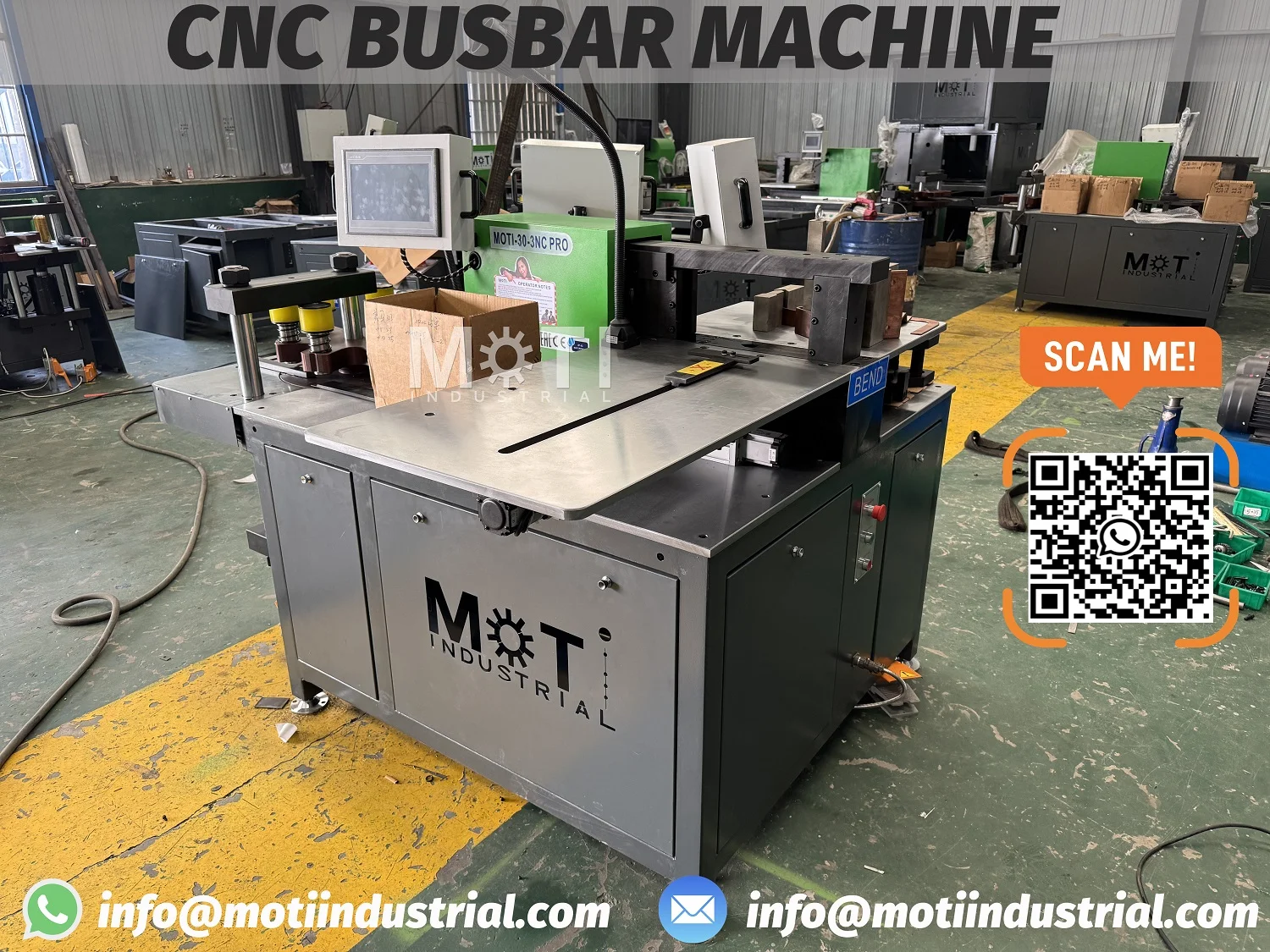

3. Overall appearance of the automatic servo CNC busbar processing machine MOTI-30-3NC PRO

The overall exterior design of the MOTI busbar machine is independently developed by us, featuring a Muslim-inspired color scheme, harmonious machine dimensions, rich configuration, and excellent machine performance.

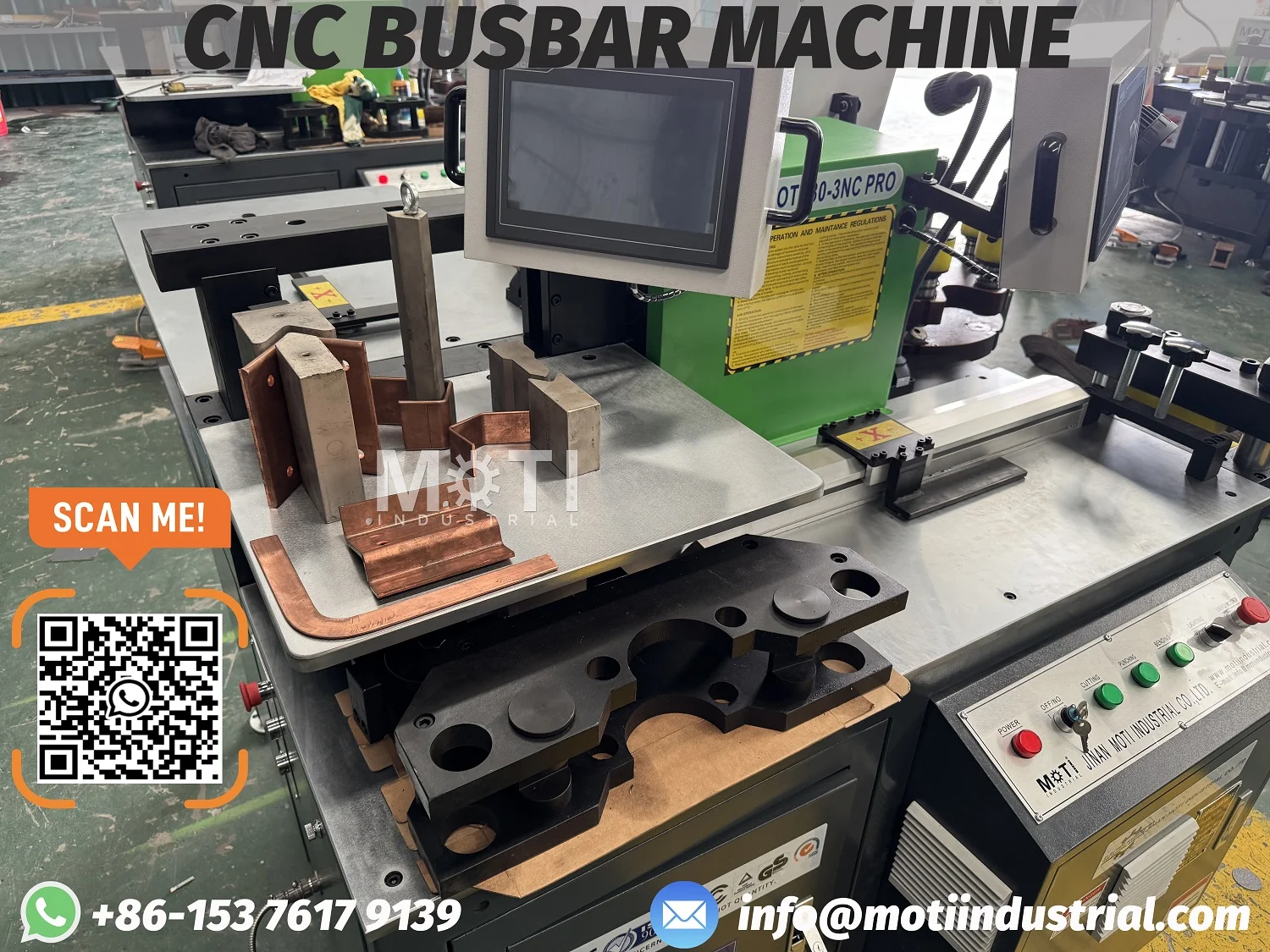

4. Bending section of MOTI-30-3NC PRO automatic CNC servo busbar processing machine

(1) The MOTI-30-3NC PRO CNC servo busbar processing machine bending unit is equipped with a Siemens PLC control system.

(2) The bending unit features a servo automatic positioning system;

the measuring baffle automatically positions itself to the bending position according to the parameters set in the bending system.

(3) The MOTI-30-3NC PRO busbar machine is equipped with vertical bending molds, flat bending molds, U-shaped bending molds, embossing molds, etc.

(4) The extra-long bending table accommodates customers' needs for bending copper bars of different lengths.

5. Punching section of automatic CNC servo 3 in1 busbar machine MOTI-30-3NC PRO

(1) The MOTI busbar punching machine is equipped with two servo positioning systems, serving as the X and Y axes for coordinate positioning.

Based on the punching parameters set in the system, the two positioning axes automatically move to the specified position.

The operator inserts the copper bar, and the machine can then perform the punching operation.

(2) In addition to coordinate axis positioning, the MOTI busbar machine is also equipped with a punching positioning pin and laser light positioning.

(3) The six-station rotary turret design allows for the simultaneous installation of six different sizes of punching dies.

The busbar punch and die changes are accomplished by rotating the turret, avoiding frequent loading and unloading of punching dies and significantly improving punching efficiency.

(4) The punching dies of the busbar machine are made of genuine Cr12Mov mold steel, possessing high strength and wear resistance.

The busbar punching dies are designed and manufactured with high precision, ensuring a long service life and are covered by a warranty.

6. Cutting section of automatic CNC servo busbar processing machine MOTI-30-3NC PRO

(1) The shearing unit is equipped with a servo positioning system. By setting the required dimensions of the copper busbar to be cut, the automatic positioning stopper will automatically move to the specified position.

(2) The shearing unit adopts a double-column structure and uses a shearing method to cut the copper busbar, resulting in no deformation, no burrs, and a smooth cutting surface.

(3)The shearing blade is made of Cr2Mov mold steel.

7. Shipment for automatic CNC servo busbar processing machine MOTI-30-3NC PRO

The MOTI busbar processing machine is coated with machine oil all over its body before shipment to prevent rusting during transportation.

The MOTI copper busbar machine body is completely wrapped in plastic film to prevent rust caused by moisture during sea transport.

The MOTI CNC busbar processing machine is shipped in a fumigation-free wooden crate for sea transport.

8. MOTI busbar machine for sale

If you are also interested in this multi-functional servo-controlled CNC busbar processing machine MOTI-30-3NC PRO, please send us an inquiry.

A detailed machine quotation will be sent to you shortly.