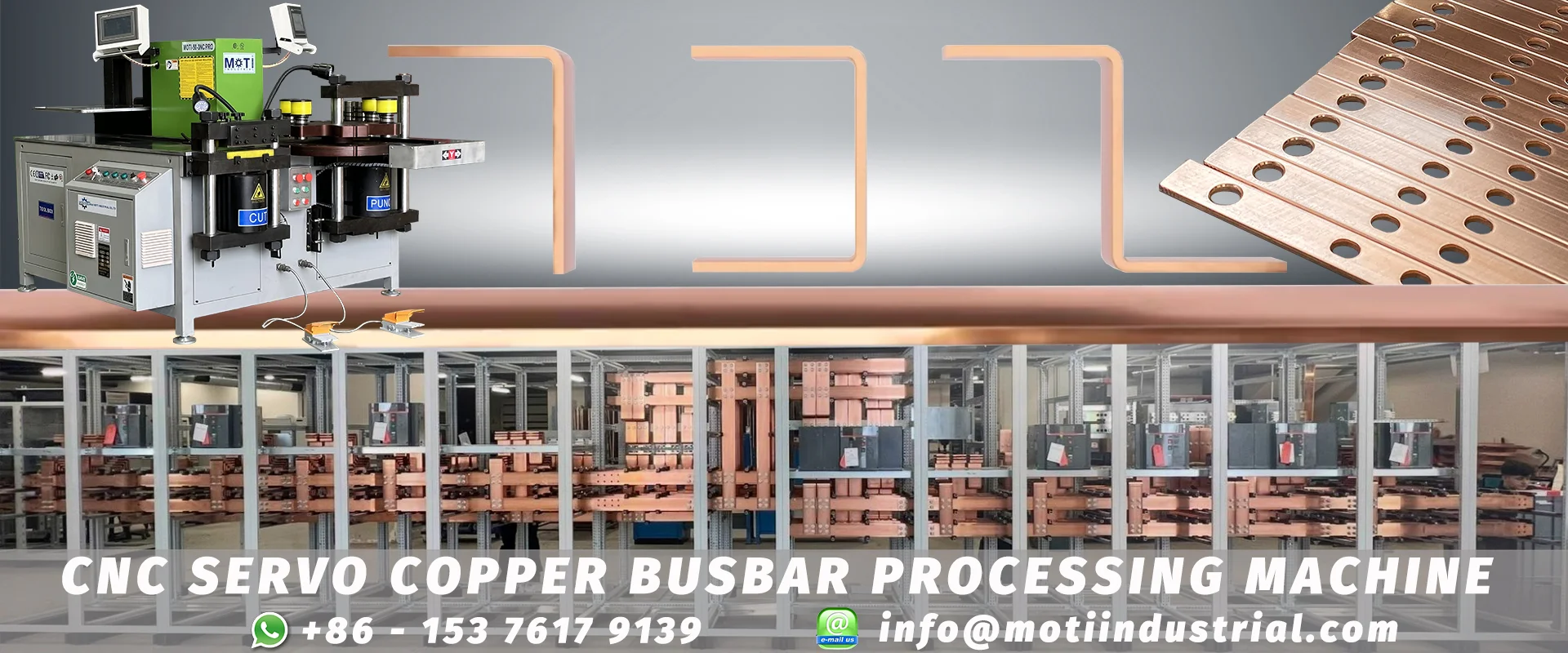

The MOTI-50-3NC PRO CNC Servo Busbar Processing Machine is an efficient, highly automated, and high-precision machine for punching, shearing, and bending copper and aluminum busbars.

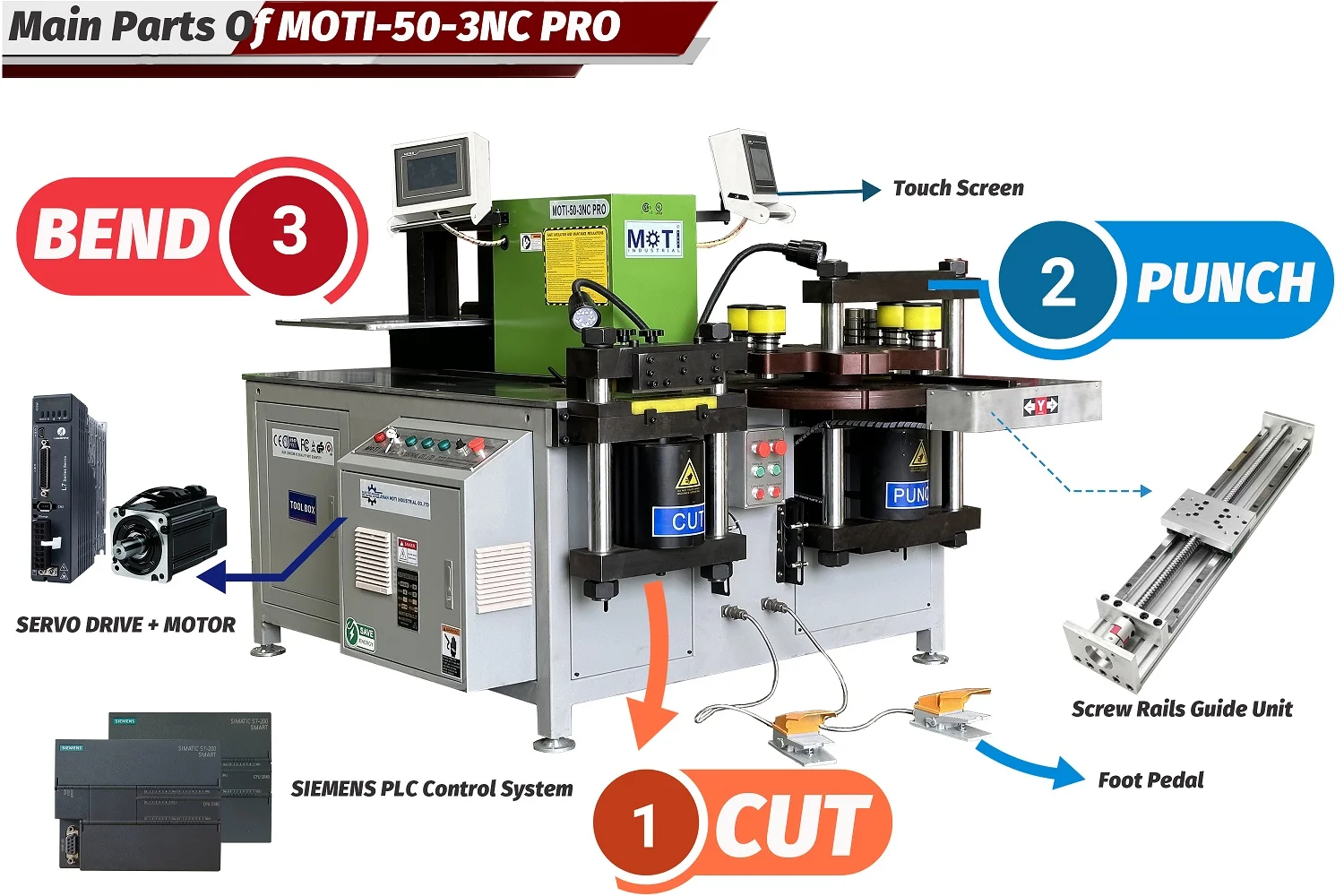

The MOTI-50-3NC PRO's shearing, punching, and bending three working units are equipped with servo-controlled automatic positioning devices.

The busbar dimensions are set via the CNC system, and the busbar machine automatically moves to the preset position to process the busbar.

For more information about this CNC Servo Busbar Processing Machine MOTI-50-3NC PRO, please continue to view the relevant content below:

1. Main Parts of CNC Servo Copper Busbar Machine MOTI-50-3NC PRO

This CNC Servo Copper Busbar Machine MOTI-50-3NC PRO is equipped with servo automatic positioning devices based on the original CNC busbar machine MOTI-50-3NC, which can improve the processing accuracy of the machine and improve work efficiency.

2. The Technical Parameter of CNC Servo Copper Busbar Machine MOTI-50-3NC PRO

| Parameter | Items | Value |

| CUT SECTION | Max. Shear Force ( KN ) | 500KN |

| Max. Shearing Thickness ( mm ) | 16mm | |

| Max. Shearing Width ( mm ) | 250mm |

| PUNCH SECTION | Max. Punch Force ( KN ) | 500KN |

| Processing Range ( mm ) | ∅4.3mm - ∅34mm | |

| Max. Punching Thickness ( mm ) | 16mm | |

| Max. Punching Width ( mm ) | 250mm |

| BEND SECTION | Max. Bend Force ( KN ) | 500KN |

| Max. Bending Thickness ( mm ) | 16mm | |

| Max. Bending Width ( mm ) | 250mm |

| Outside Dimension ( mm ) | 1850x1650x1400 mm ( Machine Dimension ) | 1870x1670x1450mm ( Package Dimension ) |

| Machine Power | KW | 3 x 5.5 KW |

| Weight ( KG ) | 1750KG ( Net Weight ) | 1800KG ( Gross Weight ) |

| Power Supply | Voltage / Frequency | 3Phase, 380V AC, 50Hz |

| Quantity Of Servo Axes | SET | 4 |

| Shearing X Axis Stroke | MM | 1000 |

| Punching X-axis Stroke | MM | 500 |

| Punching Y-axis Stroke | MM | 1000 |

| Bending Gauge Stroke | MM | 500 |

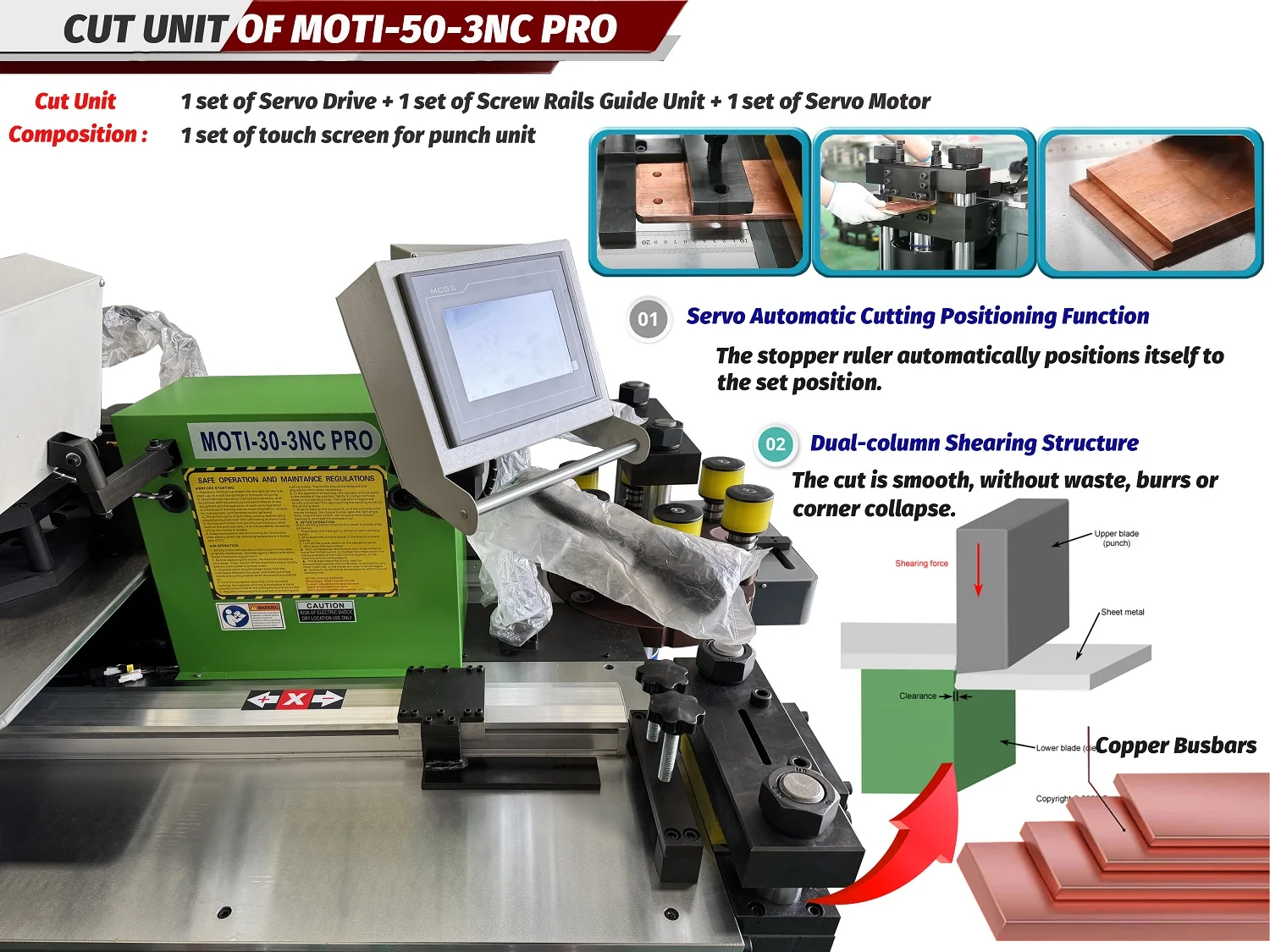

3. Cutting Unit of CNC Servo Copper Busbar Machine MOTI-50-3NC PRO

(1) Servo Automatic Cutting Positioning Function

The stopper ruler automatically positions itself to the set position by the German SIEMENS Control System

(2) Dual-column Shearing Structure

The cut is smooth, without waste, burrs, or corner collapse.

(3) Display for the cutting operation of CNC Servo Copper Busbar Machine MOTI-50-3NC PRO

4. Punch Unit Of CNC Servo Copper Busbar Machine MOTI-50-3NC PRO

(1) Servo Automatic Punching Positioning

The SIEMENS control system drives the servo controller and servo motors, utilizing coordinate positioning ( X-axis + Y-axis ) to automatically locate the copper busbar punching position set on the touch screen

(2) Laser Punching Positioning

(3) Punching Positioning Pin

(4) Display for the busbar punching operation

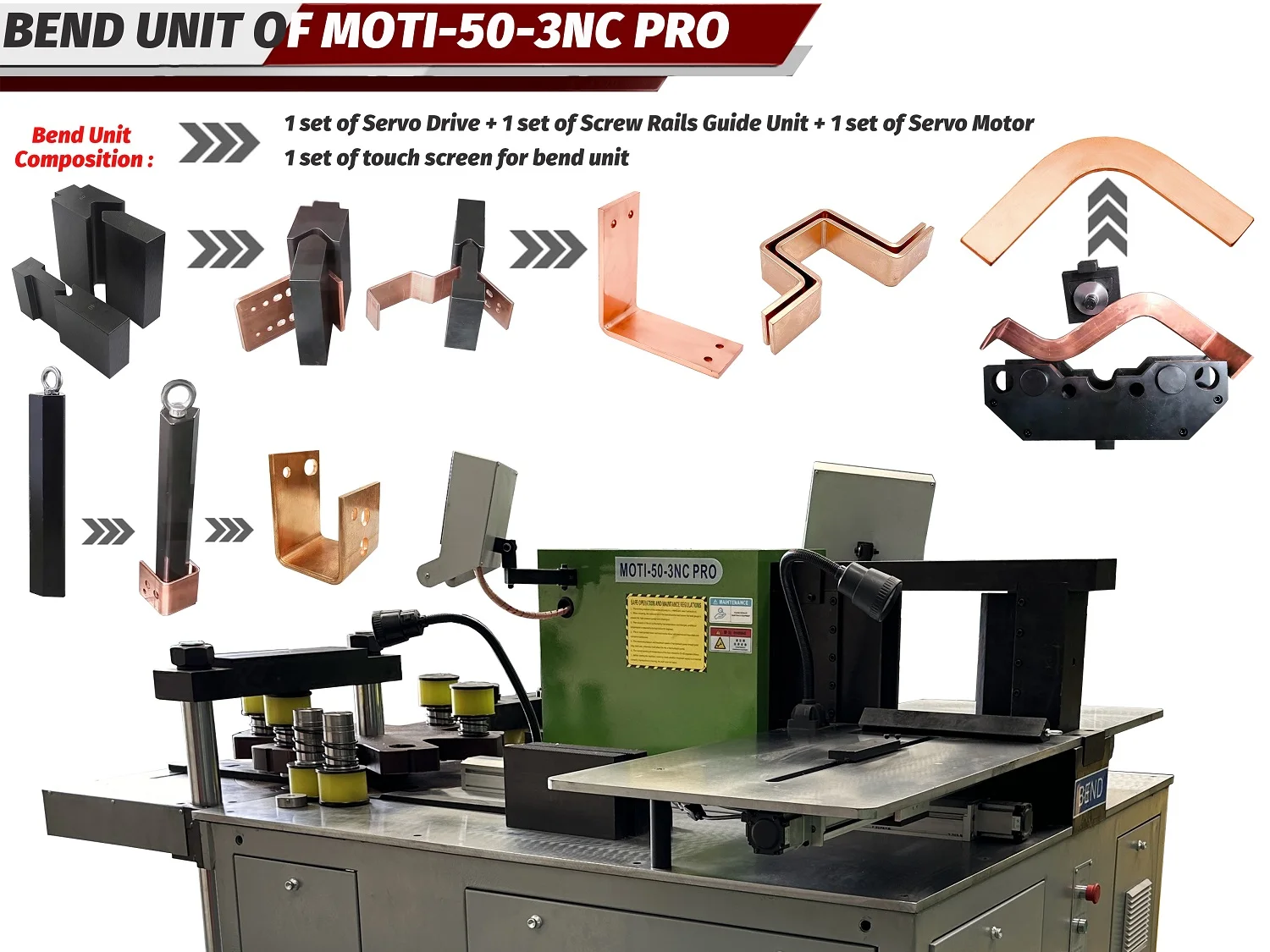

5. Bend Unit of CNC Servo Busbar Machine MOTI-50-3NC PRO

(1) The bending unit of the servo CNC busbar machine MOTI-50-3NC PRO primarily uses a servo motor to drive a high-precision ball screw to achieve slider movement.

Servo automatic positioning features fast response, high precision, and high efficiency.

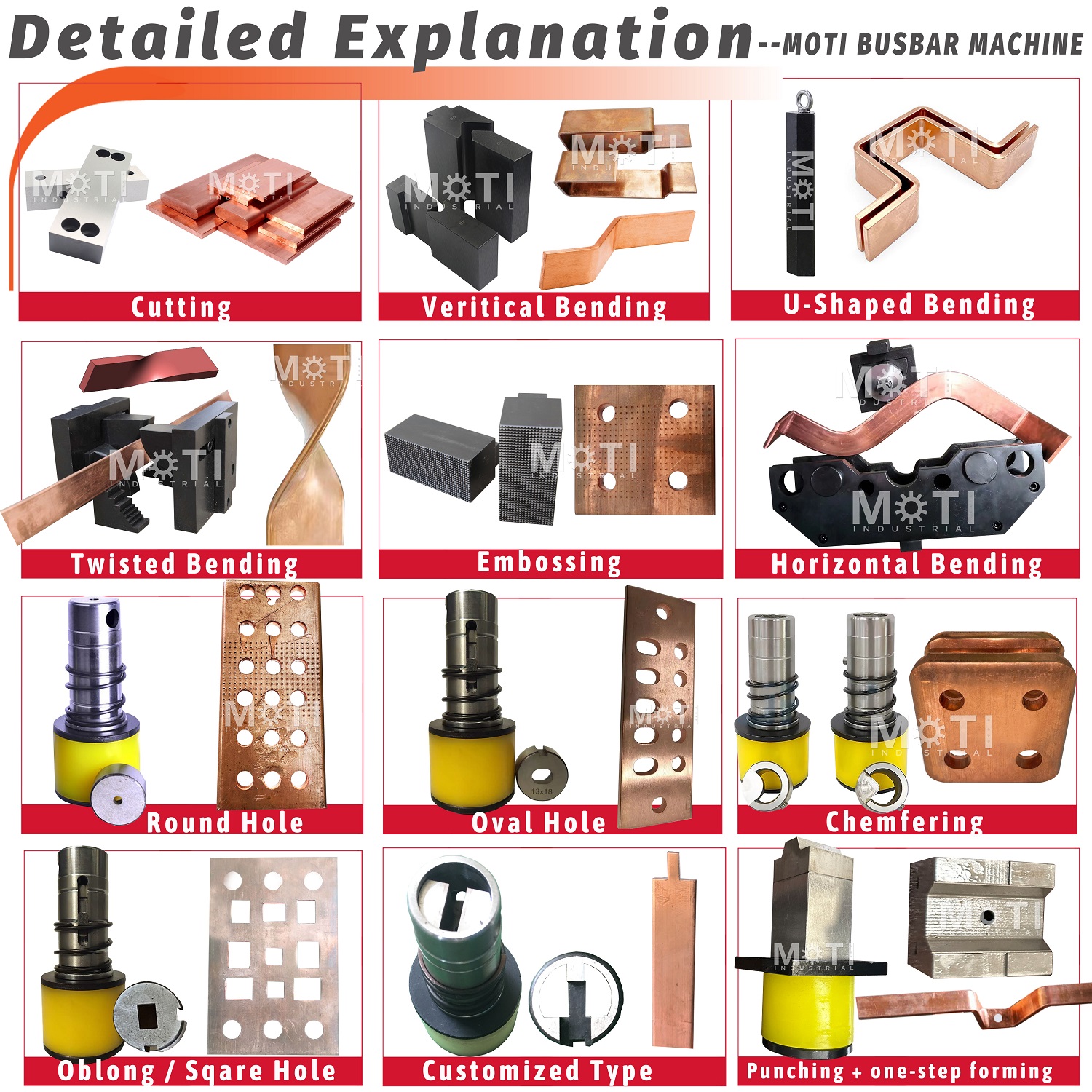

(2) By changing the different bending tools of the CNC servo busbar machine MOTI-50-3NC PRO, it can process the Vertical Bending, Edge Bending, U-shaped Bending, Z-shaped Bending,

and embossing, etc.

(3) The operation video of bending copper busbar by the CNC Servo Copper Busbar Machine MOTI-50-3NC PRO

6. Accessories of CNC Servo Copper Busbar Machine MOTI-50-3NC PRO

(1) The Standard Accessories

There are 8 sets of busbar punch and dies as the standard accessories of the CNC Servo Busbar Machine MOTI-50-3NC PRO. The punching die size can be customized according to the customer's needs.

The vertical bending tools, U-shaped bending tool, horizontal bending tools, and Embossing as the standard bending tools that belong to the standard accessories.

The upper and lower cutting blades are fitted into the machine as standard accessories.

(2) Other Options

In addition to standard configurations, we also offer custom molds. For example, Twisting Bending Tools and One-time Forming Stamping Tools are available.

Customers can provide drawings of copper busbar samples, and we can customize the molds based on the drawings.