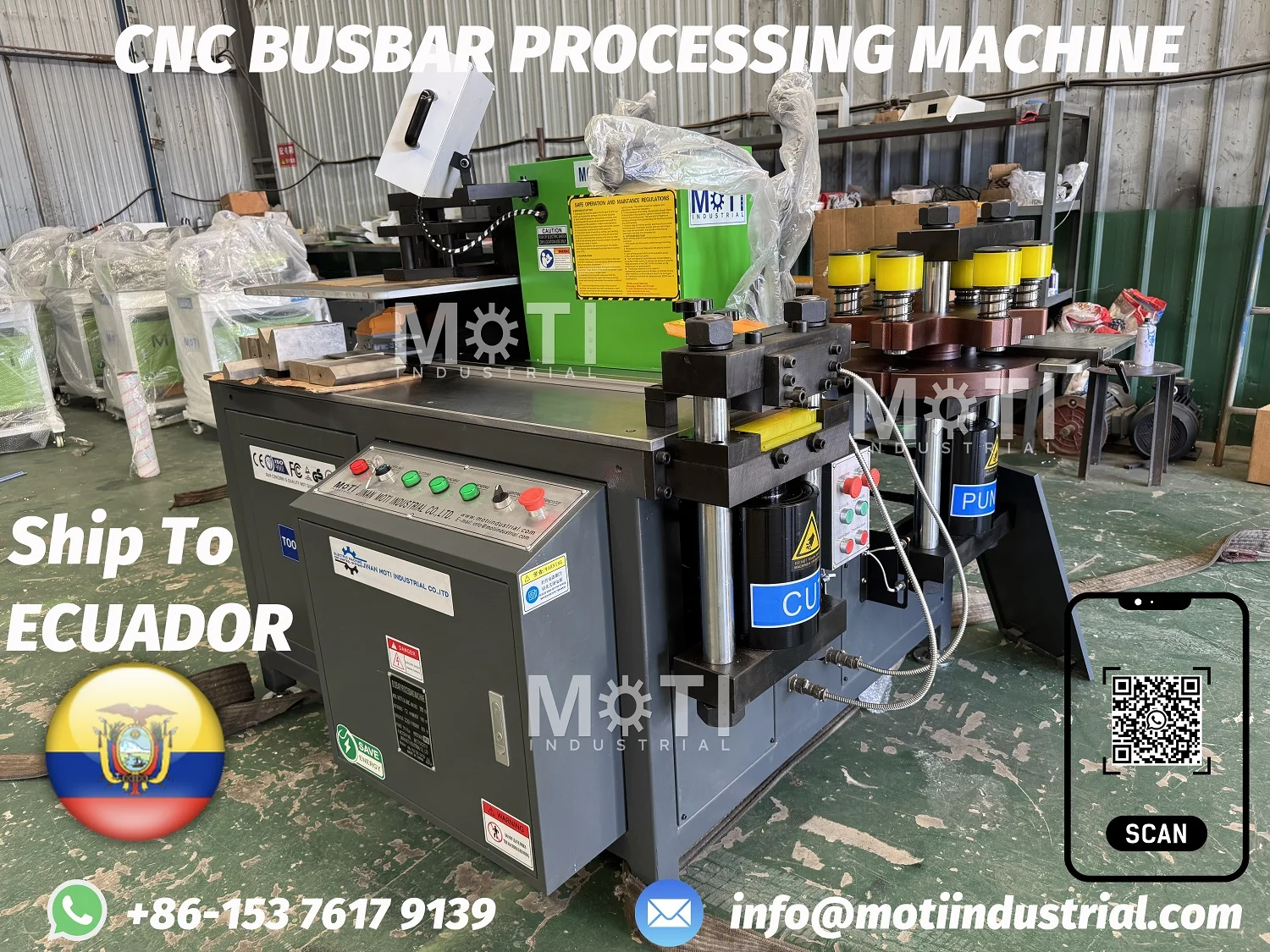

The top 1 fully automatic busbar processing machine in Ecuador

The MOTI-30-3NC PRO fully automatic busbar processing machine can perform punching, shearing, and bending operations on copper and aluminum busbars

with a maximum size of 160mm in width and 12mm in thickness, and is suitable for manufacturers of high and low voltage switchgear, transformers, and substations.

In the local South American market of Ecuador, the sales of MOTI multi-functional busbar processing machines are increasing year by year, and they have been recognized

by Ecuadorian switchgear manufacturers, making them the Top 1 in the field of copper busbar processing machines.

1. The technical parameter of automatic servo busbar processing machine MOTI-30-3NC PRO

For more details about the automatic servo busbar processing machine MOTI-30-3NC PRO, please check the following link.

The new page will provide a detailed explanation of the CNC busbar processing machine, including technical parameters.

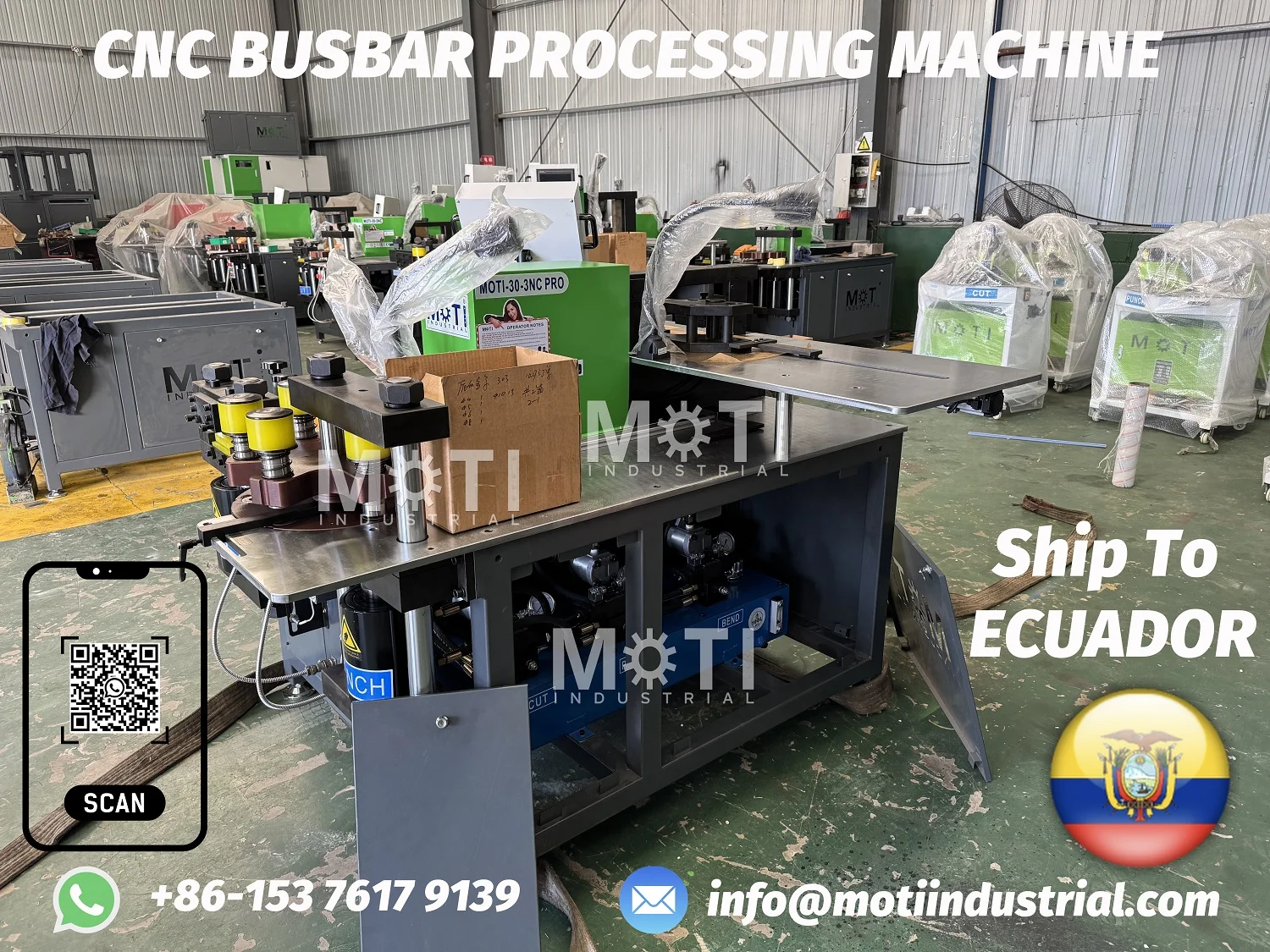

2. CNC busbar processing machine MOTI-30-3NC PRO shipping video

This is a real shipping video, showcasing the configuration and assembly process of the MOTI busbar machine in high definition.

The bending unit of the MOTI-30-3NC PRO busbar machine is equipped with a servo automatic positioning device.

Using a servo motor, the required bending angle is set in the CNC system. The 10-inch touch screen facilitates operation by the operator, and the bending positioning slider automatically moves to the specified position.

The CNC busbar processing machine MOTI-30-3NC PRO is started with a foot switch and automatically performs the corresponding bending operation.