MOTI Portable Busbar Bending Machine To Lithuania

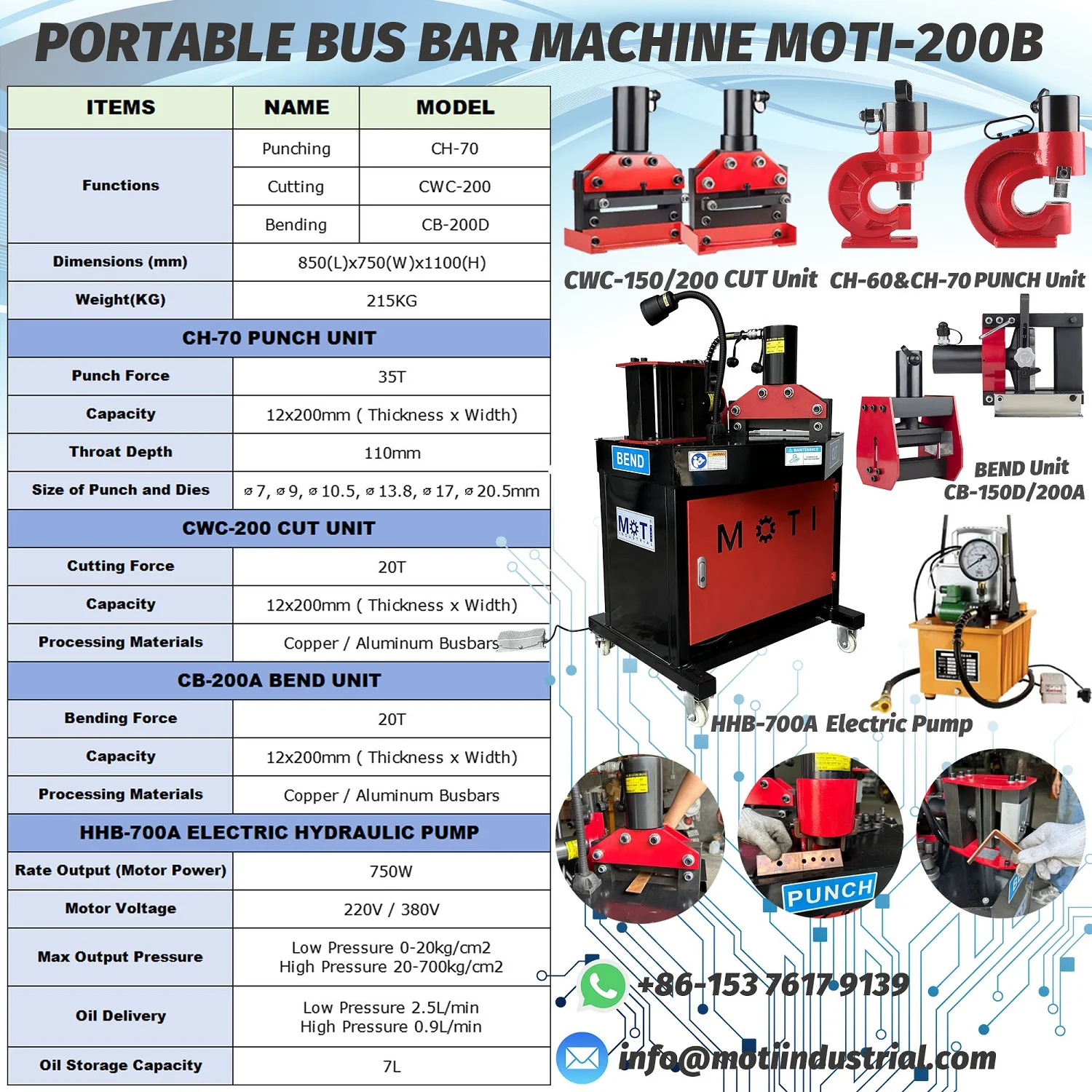

The portable busbar processing machine MOTI-200B has shearing, punching, and bending three processing units.

The main function for process different specifications of copper, aluminum busbars, easy to operate and move.

It just uses the corresponding processing unit, which can be convenient, fast for copper, aluminum row shear, punching, and bending.

1. About this item for portable busbar processing machine MOTI-200B

• Product Parameters:

Output cutting force:20ton,

Output punching force:31ton,

Output bending force:16ton,

Cutting max(Width*Thickness): 5.90"*0.39"(150mm*10mm),

Punching max(Thickness):0.39"(10mm),

Bending max(Width*Thickness): 7.87"*0.47"(200mm*12mm),

Throat depth of punching:2.75"(70mm),Punching dies:3/8"/5/8"/1/2"/3/4"

• 3 in 1 Multi-function: Punching, Cutting, Bending three functions in one machine. It is suitable for busbar processing.

• No burr after punching; The cutting surface is smooth without indentation and burr, one bending molding, high precision.

• Pure copper core motor: Pure copper core motor to ensure long-term stable operation of equipment; High-quality, high-sealing rubber pipeline to ensure that the loop will not leak hydraulic oil.

• 1000kg/cm² Oil-filled Hydraulic Gauge: The operator is to perform machining operations according to the pressure index, avoiding overload damage to equipment. Effectively avoid the impact after vibration, the instrument indication is stable and clear.

2. The technical parameter of portable processing busbar machine MOTI-200B

If you want to check more detailed information of the portable busbar cutting punching bending machine MOTI-200B, check the below link,

https://www.motiindustrial.com/article/Portable_Busbar_Machine/848.html

3. Portable Busbar Processing Machine Price

3 in 1 Electric Hydraulic Busbar Processor Cutter/Bender/Hole Puncher 700bar for Copper & Aluminum Busbars,

Industrial Grade Busbar Fabrication Tool with 6 Punching Dies, working voltage: 1Phase 110V/220V, 50Hz/60Hz

Contact us, the detailed quotation will be sent to you later.