The heavy-duty CNC Copper Busbar Processing Machine MOTI-80-3NC, with its ultra-high load-bearing capacity, has a processing range of 20x300mm, making it suitable for shearing, punching, and bending copper busbars that are more than 15mm thick and 200mm wide.

For more detailed information about heavy-duty CNC Copper Busbar Processing Machine MOTI-80-3NC, please continue reading:

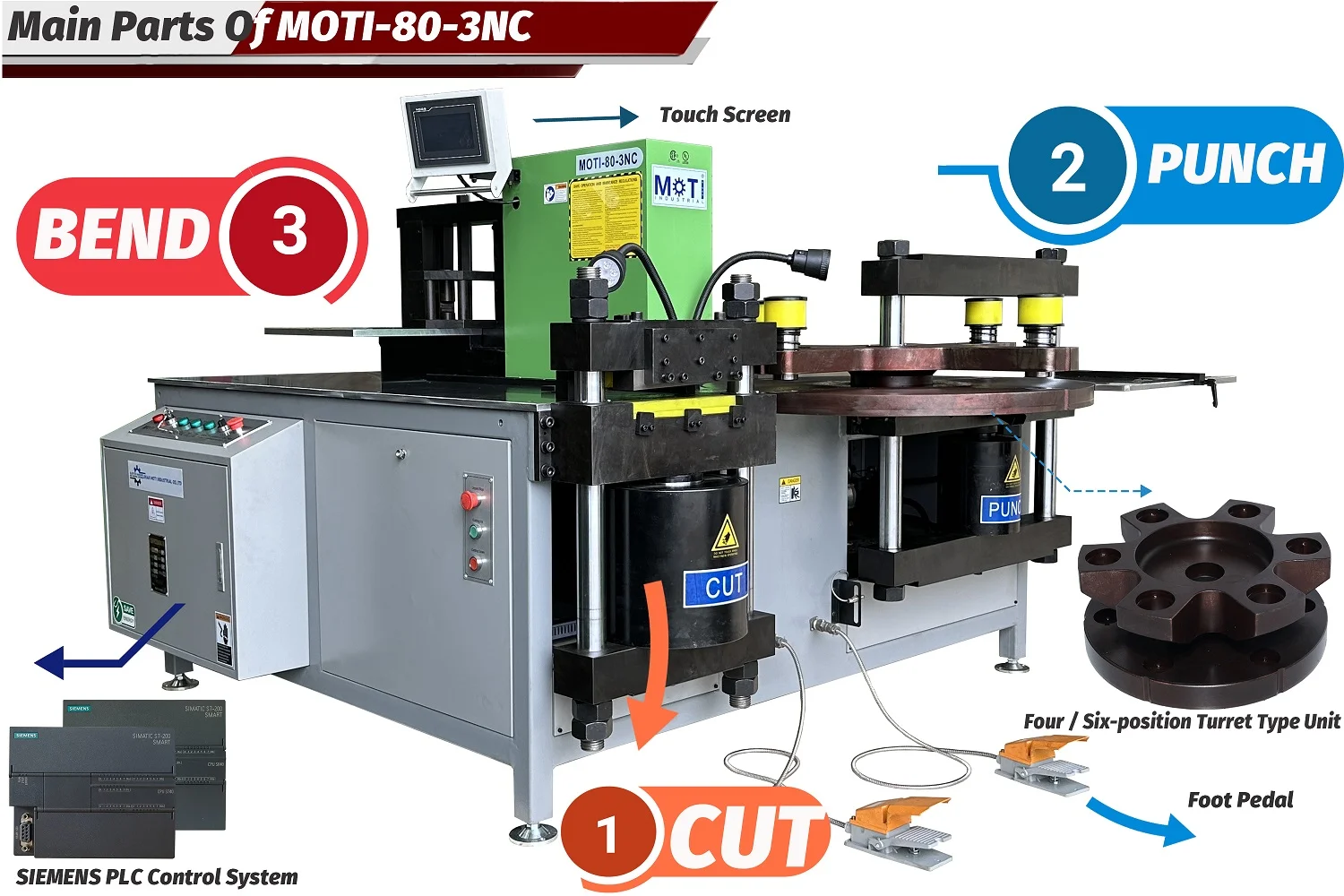

1. Main parts of CNC Copper Busbar Processing Machine MOTI-80-3NC

(1) Three sets of 7.5Kw motors with hydraulic pumps systems

(2) Germany SIEMENS controls system

(3) 10inch touch screen

(4) Real-materials: Busbar Punch & dies ( Cr12Mov mold steel )

2. The Heavy-duty 3 in 1 Busbar Machine MOTI-80-3NC Operation Demonstration

In the video, MOTI INDUSTRIAL demonstrated a simple operation of the MOTI-80-3NC CNC 3 in 1 busbar machine's punching, shearing, and bending functions using a thick copper busbar.

3. The Technical Parameter of CNC Busbar Processing Machine MOTI-80-3NC

| DESCRIPTION | ITEMS | MOTI-30-3NC | MOTI-50-3NC | MOTI-80-3NC |

| PUNCH | Max. Punch Force ( KN ) | 300 | 500 | 800 |

| Punch Diameter Range ( MM ) | ∅ 4.3 - ∅ 25 | ∅ 4.3 - ∅ 34 | ∅ 4.3 - ∅ 34 | |

| Max. Thickness ( MM ) | 12 | 16 | 20 | |

| Max. Width ( MM ) | 160 | 250 | 300 |

| CUT / SHEAR | Max. Cut Thickness ( MM ) | 12 | 16 | 20 |

| Max. Cut Width ( MM ) | 160 | 250 | 300 |

| VERTICAL BEND | Max. Bend Force ( KN ) | 300 | 500 | 800 |

| Max. Thickness ( MM ) | 12 | 16 | 20 | |

| Max. Width ( MM ) | 160 | 250 | 300 |

| HORIZONTAL / EDGE BEND | Max. Thickness x Thickness ( MM ) | 100mm x 10mm | 120mm x 12mm | 120mm x 12mm |

| Max. Angle ( Degree ) | 90° | 90° | 90° |

| DIMENSION | MM | 1790 x 1400 x 1420 | 1950 x 1560 x 1420 | 2060 x 1600 x 1560 |

| MOTOR POWER | KW | 3 x 4.0 KW | 3 x 5.5 KW | 3 x 7.5 KW |

| WEIGHT | KG | 1450KG | 1750KG | 2350KG |

| CNC PRECISION | Bend Precision | ± 1° | ± 1° | ± 1° |

| Repeat Bend Precision | ± 0.3° | ± 0.3° | ± 0.3° |

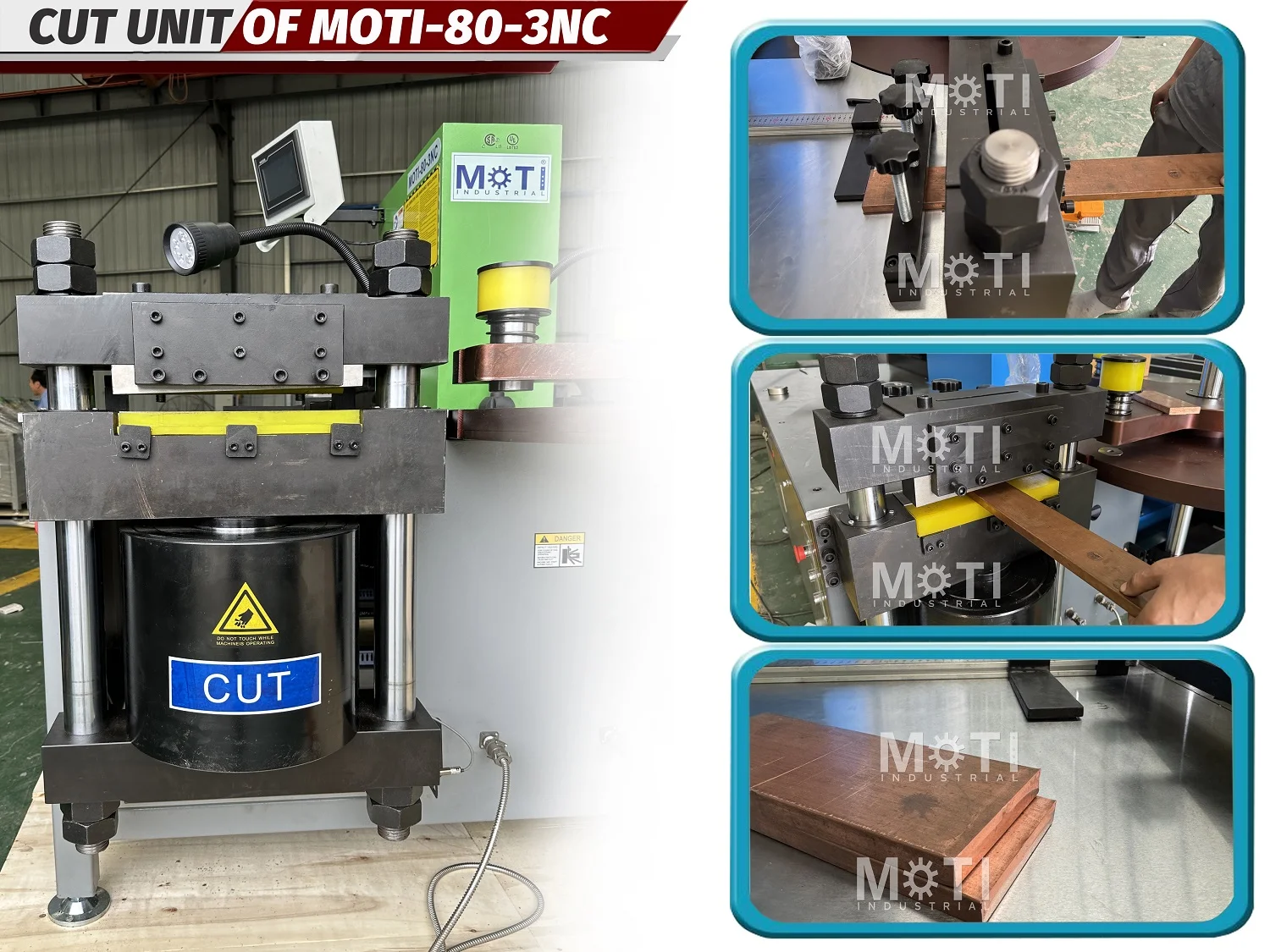

4. Cutting unit of CNC Busbar Processing Machine MOTI-80-3NC

(1) The 270mm diameter shearing cylinder can easily shear copper busbars up to 20mm thick

(2) The cutting unit is equipped with 7.5Kw motor and hydraulic pump system, ensure the load-bearing capacity of machine-processed copper busbars

(3) The double-column shear structure

(4) The shearing design ensures zero waste and no collapse of the copper busbar during cutting, resulting in a smooth, burr-free cut.

5. Punch unit of CNC Busbar Processing Machine MOTI-80-3NC

(1) The four-position turntable with a diameter of 9500mm

(2) The punching unit insall 7.5Kw motor and hydraulic pump system

(3) The extra-large busbar punching die

(4) Punching positioning method:

A. Coordinate Punching positioning B: Laser Light Punching Positioning C: Punching Pin Positioning

6. Bending Unit of CNC Busbar Processing Machine MOTI-80-3NC

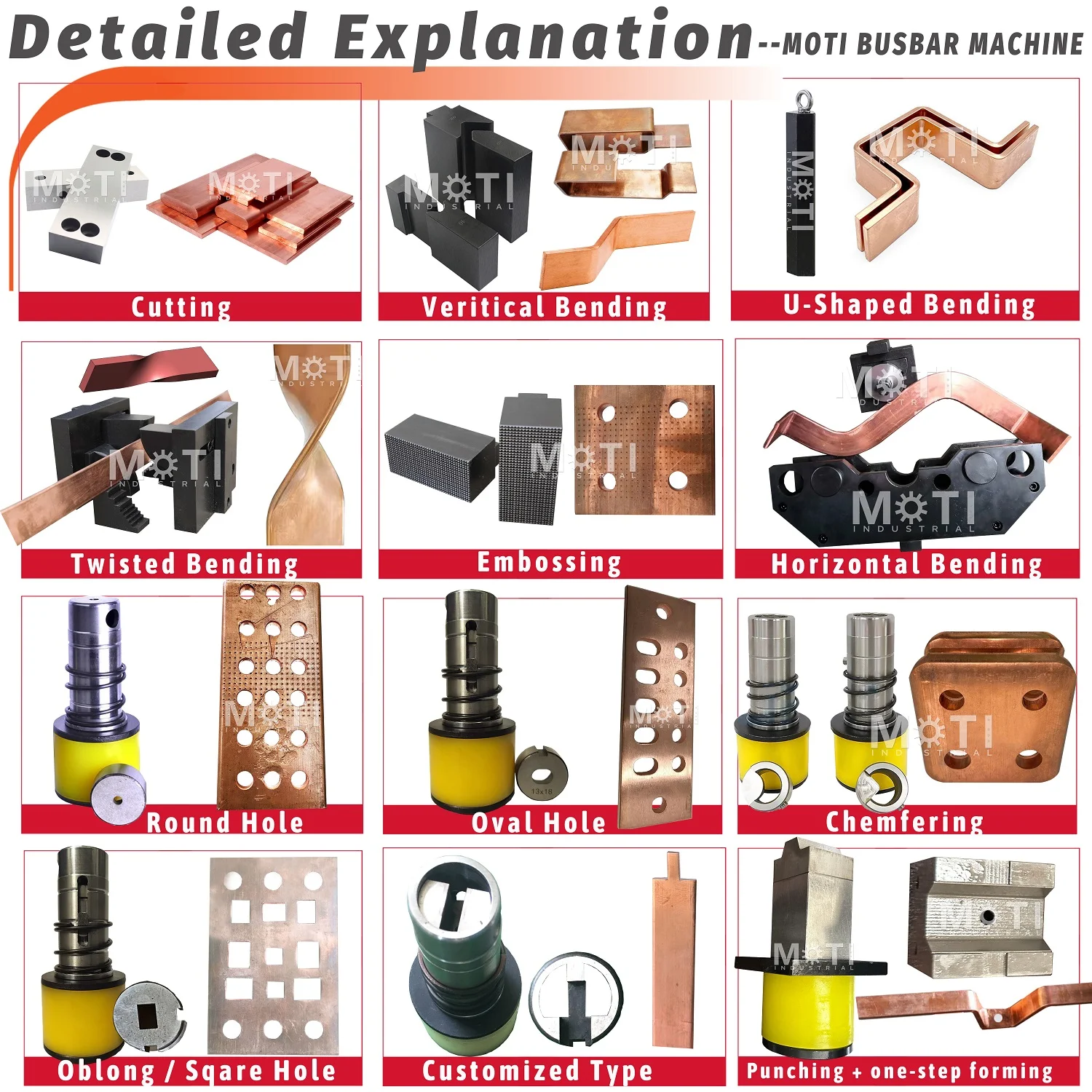

(1) The standard bending tools included in the Vertical Bending Tools, Horizontal Bending / Edge Bending Tools, U-shaped Bending Tool, Embossing Mold, etcs.

(2) The bending unit with 7.5Kw motor and hydraulic pump system

(3) 10inch touch screen

(4) Germany SIEMENS Control System

7. The Accessories And Tools of CNC Busbar Processing Machine MOTI-80-3NC

To meet diverse customer needs, we can customize molds and accessories.

We can design and develop custom molds based on customer copper busbar sample drawings.