Features of Dry-type transformer winding machine

Features of Transformer Winding Machine

1. What is a transformer winding machine?

Let's first understand the down-converter Transformer Winding Machine.

Its winding adopts a computer CNC control system, and the spindle is accurately positioned by CPLD decoding and speed measurement.

Then it is equipped with a constant current chopper to drive the stepping motor wiring, which is fast and precise to ensure the normal operation of the equipment.

It is widely used in the manufacture of switching power supply transformers, supplies, inductance coils, Japanese-shaped transformers and other products.

If you want to know more details about the Transformer Winding Machine, please the below link,

https://www.motiindustrial.com/images/Horizontal_winding_machine/494.html

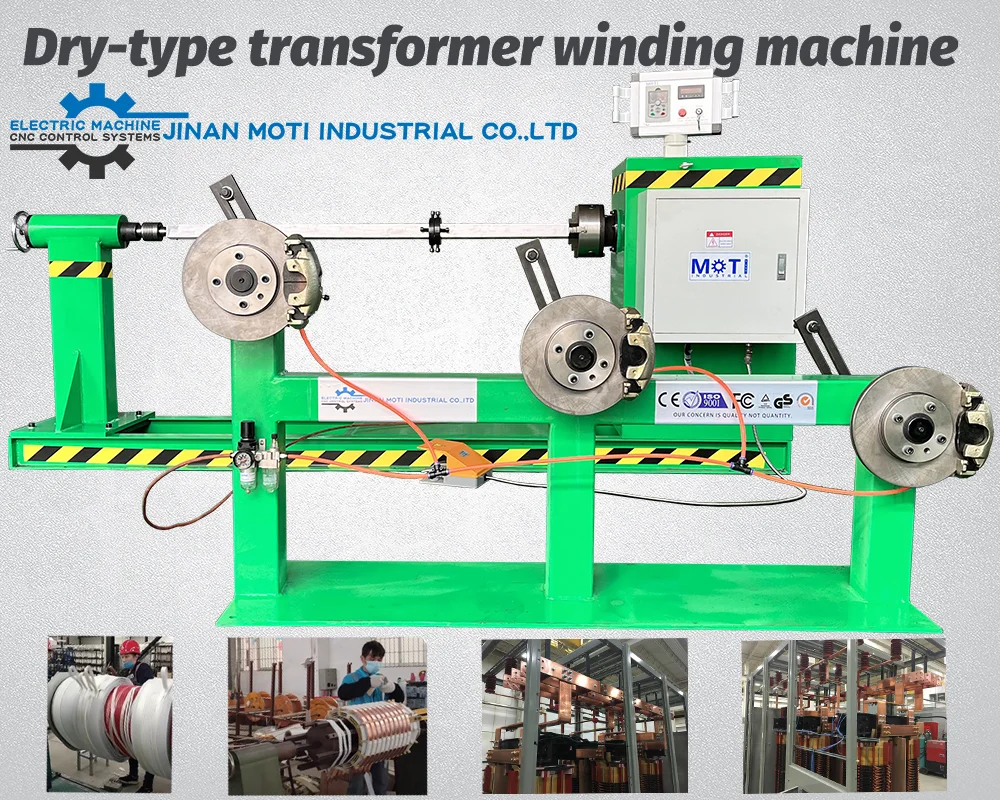

2. The composition of the transformer winding machine

Transformer winding machines are mainly used in the winding processing of high and low voltage windings of transformers.

They are mainly divided into two categories: automatic and numerical control. The numerical control model is currently the most widely used equipment.

Transformer winding machines have undergone several generations of improvement and development. , has developed rapidly in function and processing capacity.

The structure of the transformer winding machine is mainly composed of the fuselage, the frame, the main shaft mechanism, the tailstock support, the frame and other components.

Since the transformer coil has a certain weight and needs to bear the external force of beating and shaping during processing, the winding The machine body and frame are made of steel with strong bearing capacity.

According to the size of the processing capacity of the machine, it is divided into three categories: small, medium and large, and the load-bearing capacity is different.

3. The key components of the transformer winding machine

The spindle system is the key component of the transformer winding machine.

It amplifies the torque of the motor after multi-stage deceleration, which has met the processing of the winding of the transformer coil.

Generally, the structure of the motor + deceleration mechanism is used to configure, the speed change mechanism Generally, it is realized by motor variable frequency speed change or gear switch of reducer.

The data storage segment of the transformer winding machine is in the same step sequence from 0 to 999.

It can wind in high-speed forward and reverse directions, the number of turns is accurate, and the data is automatically saved when there is a problem in use.

The CNC can monitor and display the production status, simple setting and convenient operation.

Transformer winding machine has been the main application model for processing transformer coils.

Keywords of Transformer Winding Machine

Transformer Winding Machines for Distribution Transformer / Coil Winding Equipment / Transformer Winding Machine Manufacturers / Coil Winding Processes

High Speed Bench Winders / Coil Winding Machines / Coil Winders / Distribution Transformer Automatic Winding Machine

Manufacturer of Transformer Winding Machine / Distribution Transformer Automatic Winding Machine / Traction Transformers Automatic Winding Machine

Distribution Transformer Winding Machine / Manual transformer winding machine / Horizontal winding machine