CNC Copper Busbar Machine MOTI-30-3MAX to Italy

MOTI INDUSTRIAL Group, the copper busbar machine manufacturer, is deeply engaged in offering a wide range of busbar cutting punching and bending machines,

copper bus bar bending machines, CNC busbar processing machines, and cable crimping tools.

12x200mm capacity of MOTI-30-3MAX three-in-one busbar machine can punch, cut, and bend copper or aluminum busbars with high production efficiency.

This MOTI series busbar processing machine mainly applies to the manufacturing industry of high and low-voltage switch cabinets, electric control panel manufacturers, and power transformers.

1. The featuers of CNC Busbar Processing Machine MOTI-30-3MAX

(1) Double feeding structure

We updated the design for adding the feeding structure for the cutting unit and punching unit.

This design is convenient for customers to build temporary shelves when processing copper bars that are too long, reducing space occupancy and improving work efficiency.

(2) Larger processing range 12x200mm

Since many customers need to process copper bars with a width exceeding 160mm but a thickness within 12mm, customers are limited by the processing range and can only choose the MOTI-50-3NC busbar machine with a processing range of 16x250mm.

We changed the machine structure and appearance design, increased the machine's processing range, and allowed customers to process copper bars with a processing range of 12x200mm.

(3) 3 in 1 busbar processing machine

There are 3 sets of hydraulic motors and pumps install the CNC busbar cutting punching bending machine ensure three units can do work at the same time.

2. The technical parameter of CNC Copper Busbar Machine MOTI-30-3MAX

If you want to know more detailed information of the three in one busbar machine, check the below link,

https://www.motiindustrial.com/article/cnc_busbar_processing_machine_3_in_1_/872.html

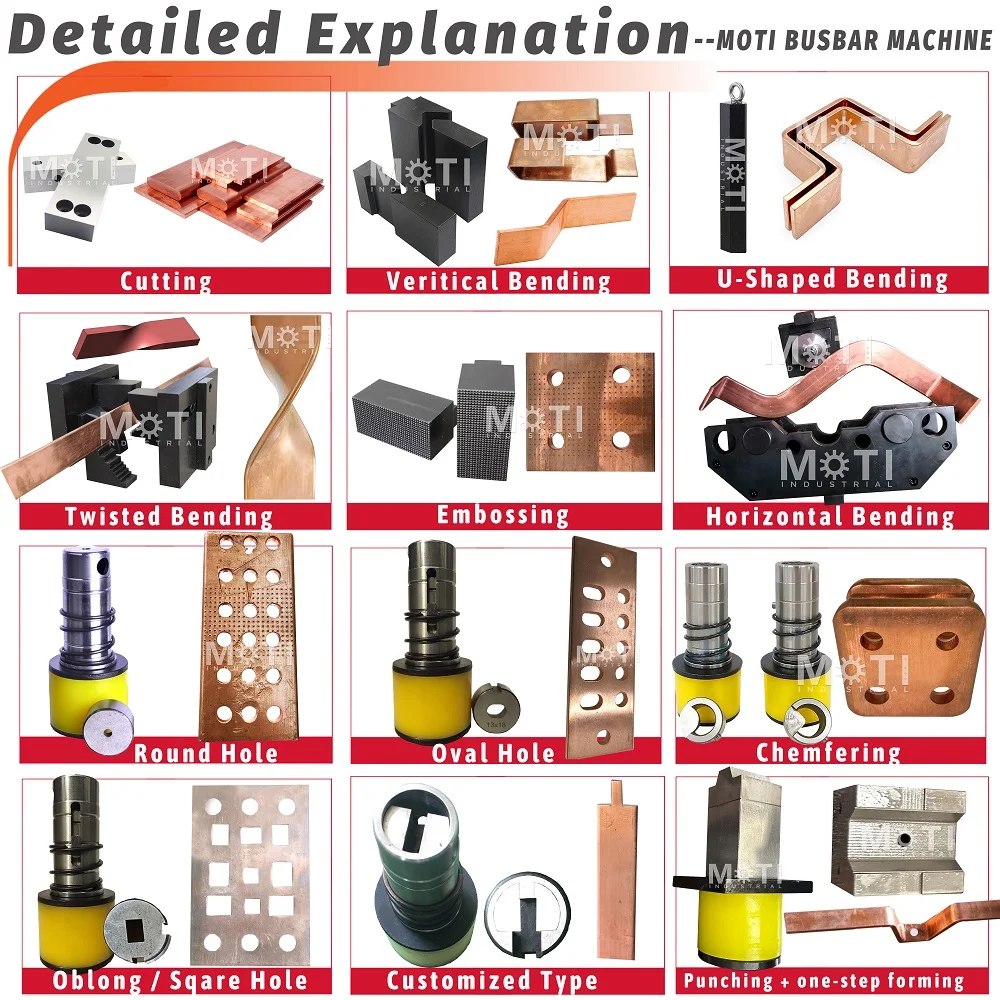

3 Display for all parts of CNC Busbar Processing Machine MOTI-30-3MAX before shipment