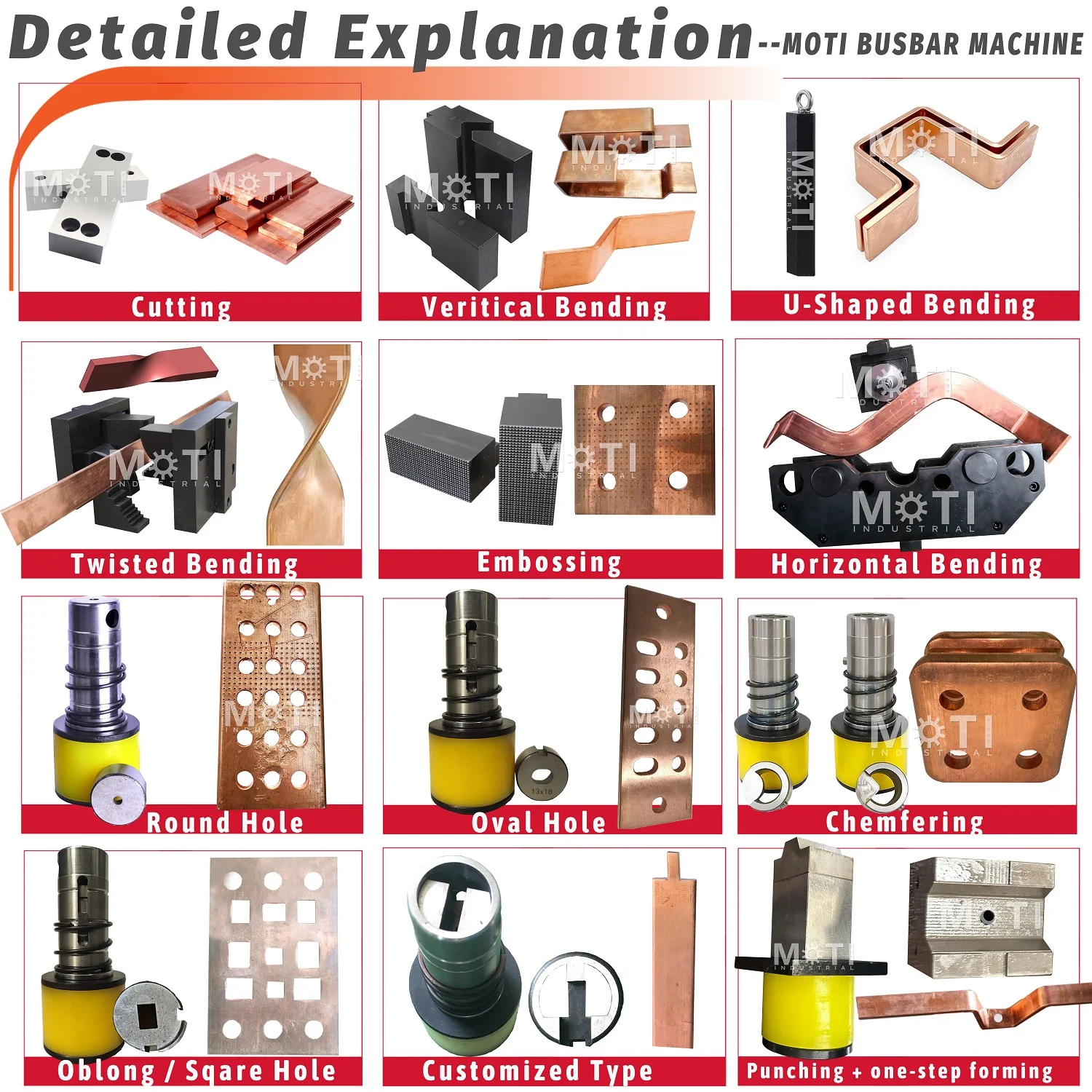

At MOTI INDUSTRIAL, we provide a wide capacity of copper busbar processing machines. We can customize the busbar fabrication machines according to the customer’s requirements. Economical price. High efficiency. A variety of shapes and sizes of long-life busbar punches and dies with long-life working.

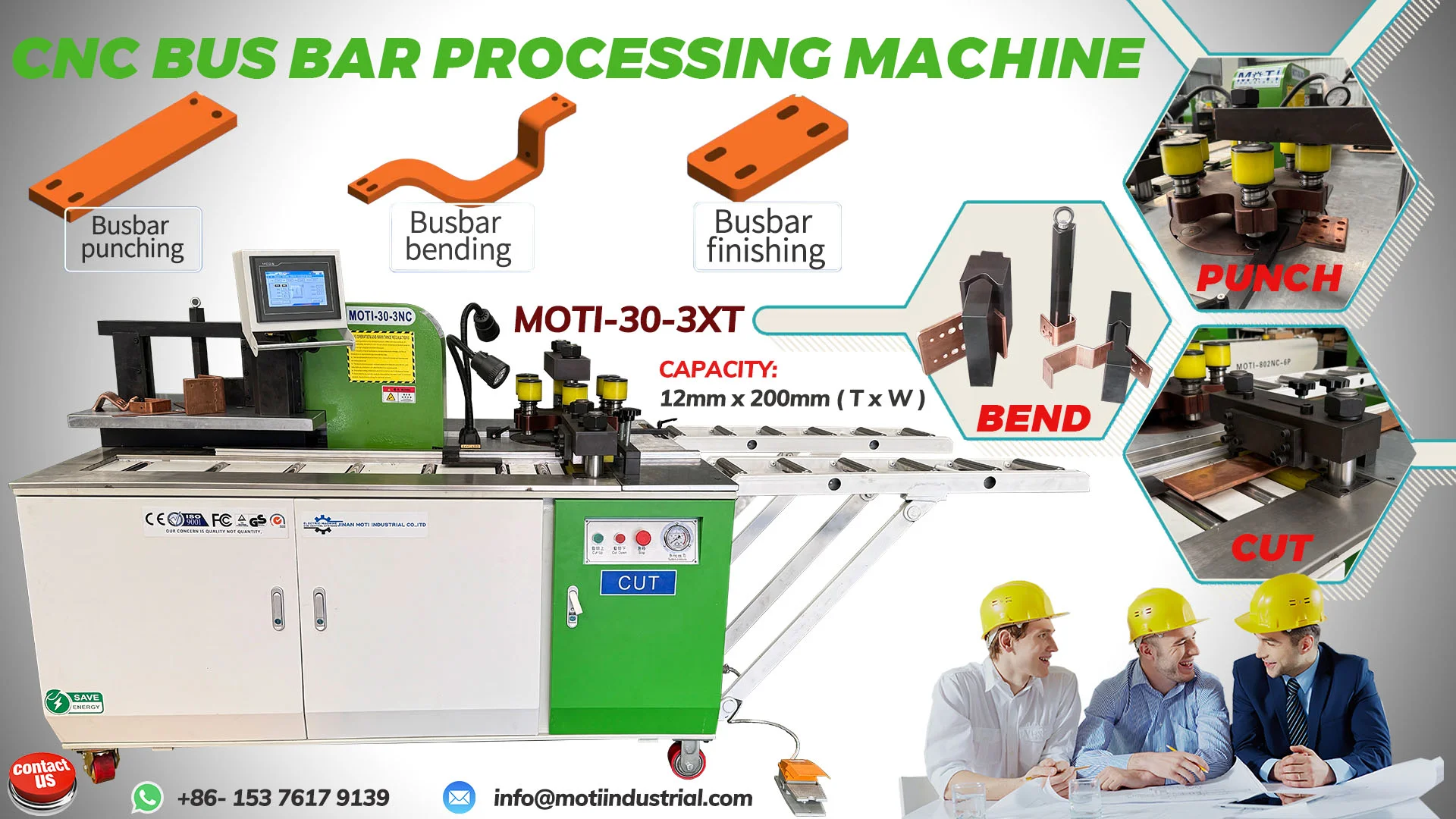

The multifunction busbar processing machine MOTI-30-3XT is a patented product developed by MOTI INDUSTRIAL Group in 2024.

According to the customer's feedback on the before purchased busbar processing machines, we have upgraded some functions and details of the new CNC copper busbar processing machine MOTI-30-3XT to make it easier to operate and improve the customer's work efficiency.

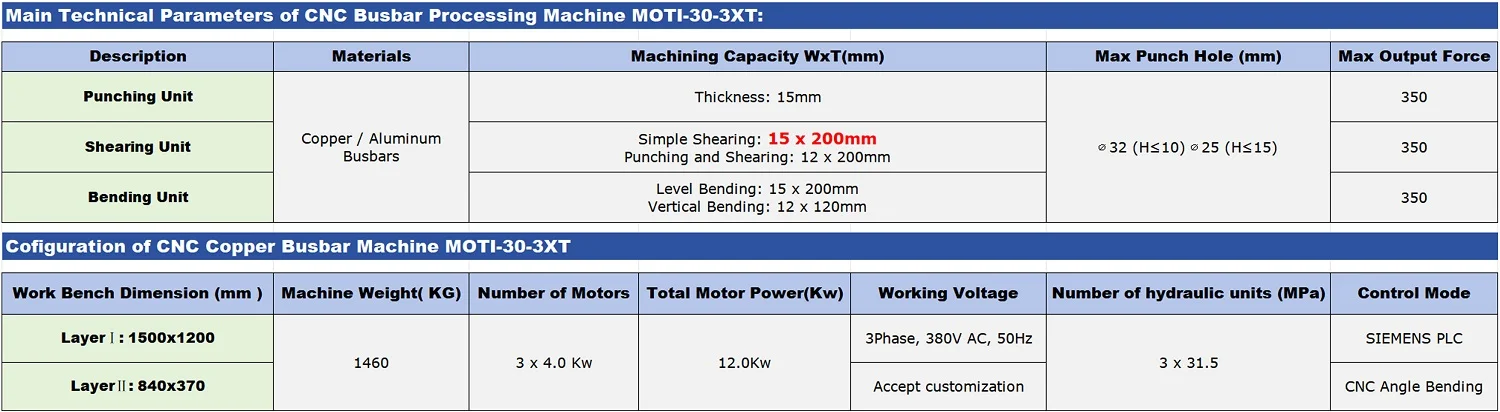

Customers can choose the most suitable busbar processing machine model according to the maximum processing size of the copper busbar they need to process.

Mainly the maximum thickness and width of the copper busbar.

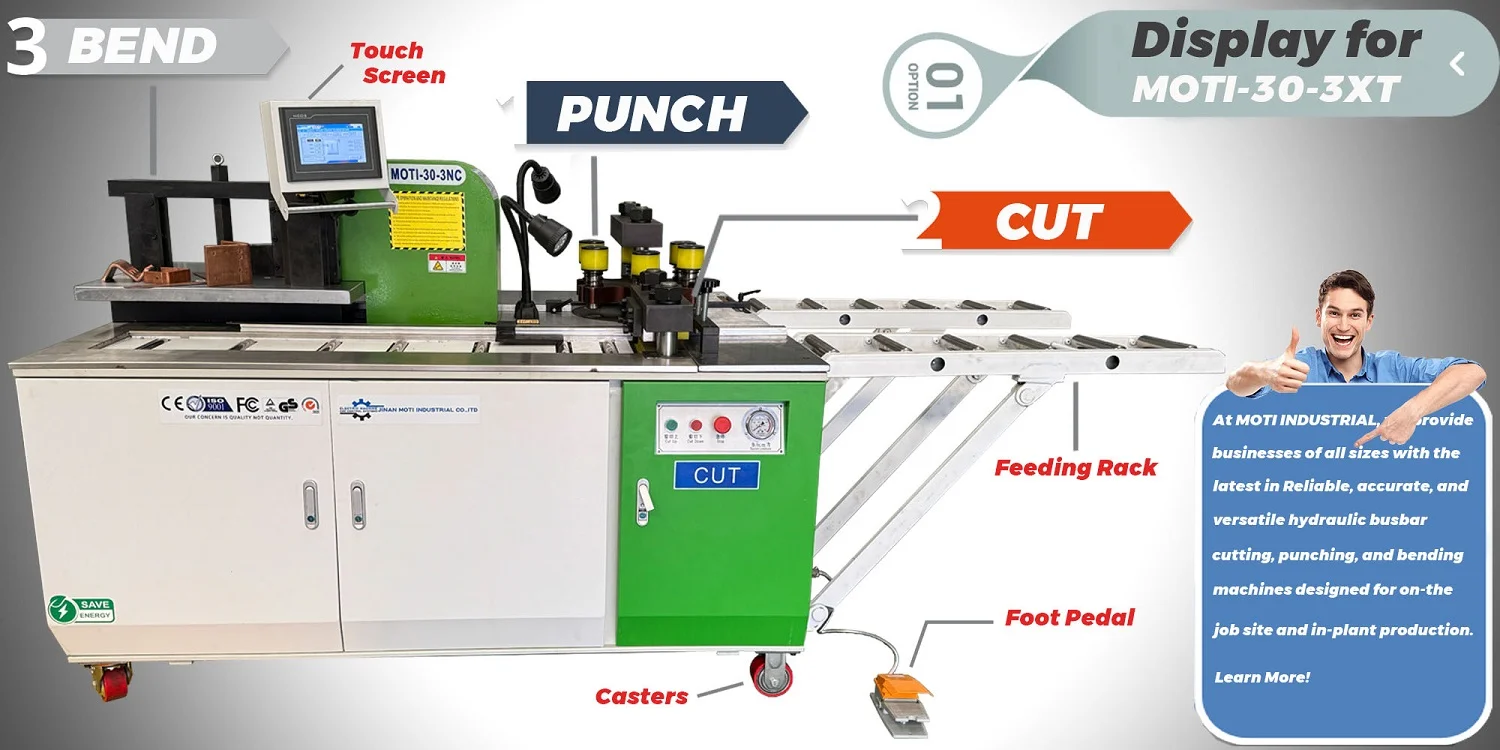

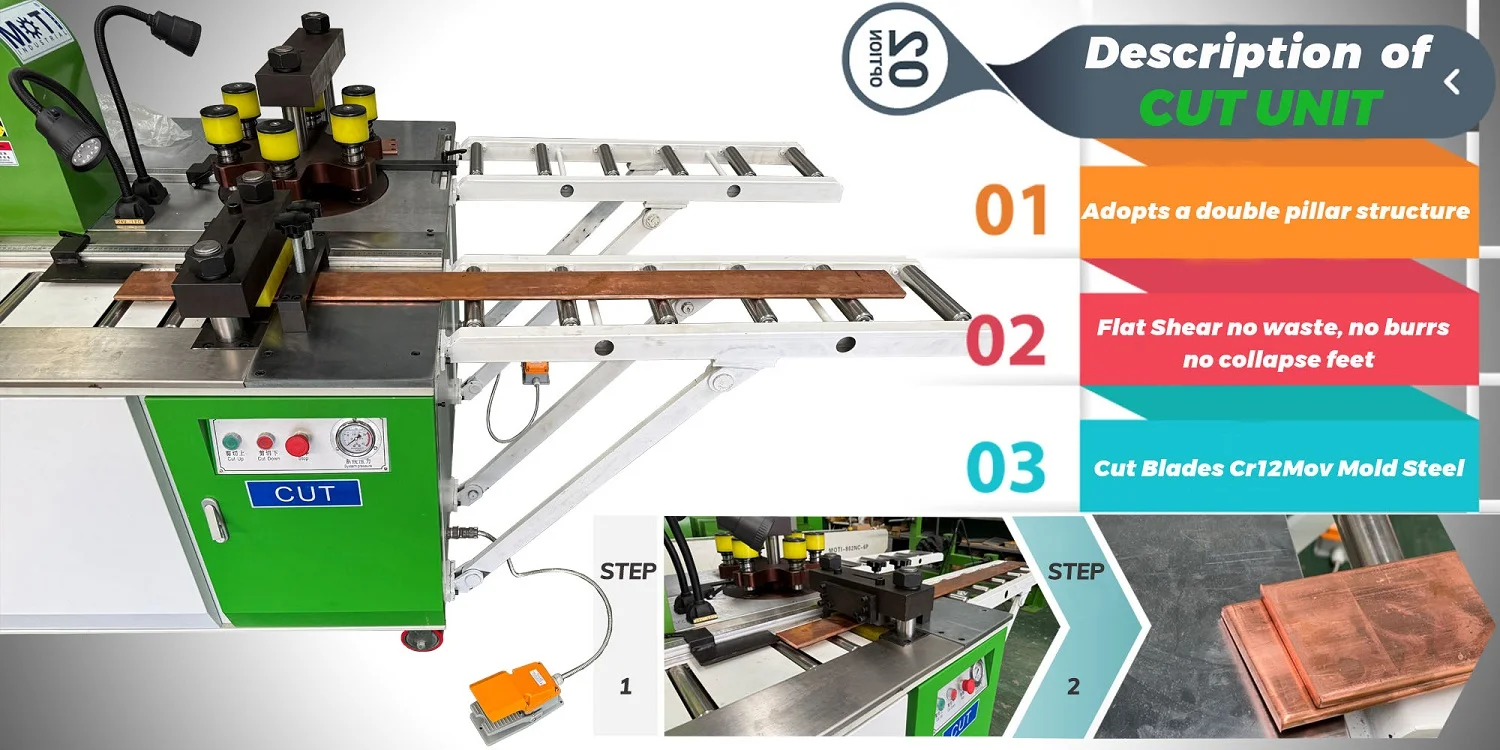

The shearing unit adopts a double pillar structure with a novel and unique design rendering reasonable force bearing, and thus effectively guarantees long-term use without deformation.

The flat shear has no waste, no burrs, no collapse feet

The original materials of the cutting blade adapt to the Cr12Mov mold steel.

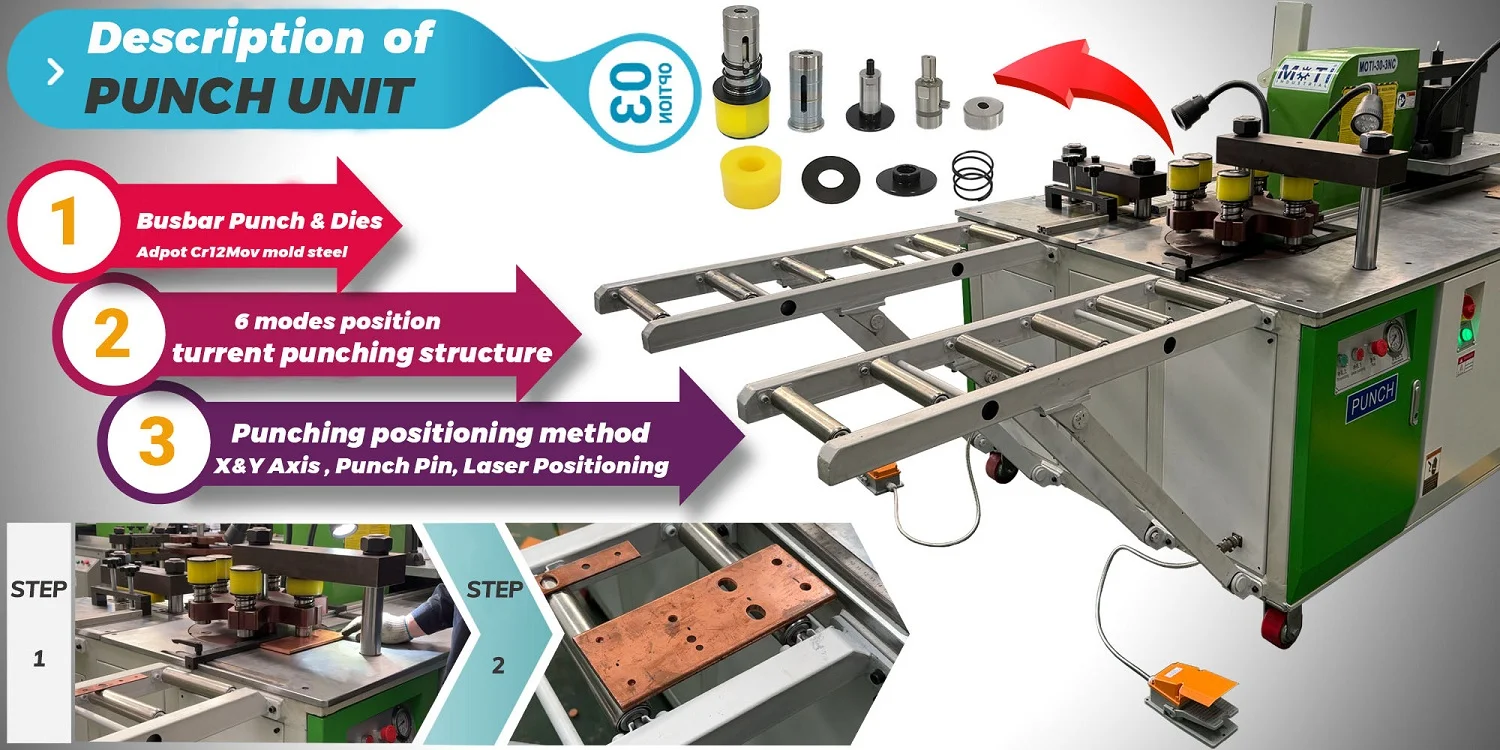

The punching unit adopt turret type, capable of storing six punching dies

The punching positioning method: 1. X&Y Axis positioning 2. Punch Pin Positioning 3. Laser Positioning

The orignal material of copper busbar punch and dies use the Cr12Mov mold steel

The bending unit uses the closed type of structure and CNC angle control mode, allowing easy operation and high accuracy;

This copper busbar machine adopts the design approach of the double-layer workbench, truly realizing the simultaneous working of three stations without mutual interference;

There are 3 sets of electric motors and hydraulic pumps engine system can ensure the cutting punching and bending of three units can do work at the same time;

The Germany SIEMENS PLC control is stable and reliable.