ELECTRIC HYDRAULIC PUMP

Designed by MOTI INDUSTRIAL. The electric pump and other hydraulic tools equipped with

lifting, pressing, bending, bending row, straightening, shearing, assembly, disassembly and many other jobs.

Product functions of Electric Hydraulic Pump

1. the hydraulic electromagnetic pump has simple operation, wide range of applications and other functions

2. High and low pressure output in two stages, large oil volume

3. low pressure plunger type, increase the effective pressure

4. automatic protection to ensure no leakage during use

5. pressure overload protection device to avoid damage to equipment due to overpressure

6. single oil circuit, electromagnetic wired remote control, suitable for all kinds of equipment such as cutting, piercing, pipe bending, jacking, etc.

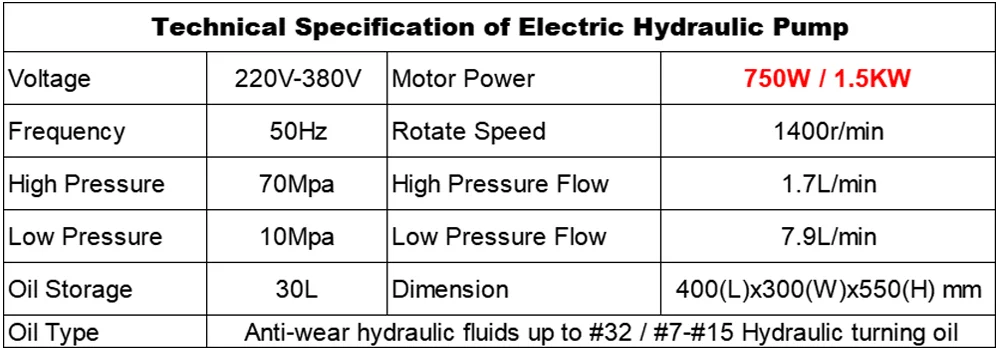

Technical Specifications of Electric Hydraulic Pump

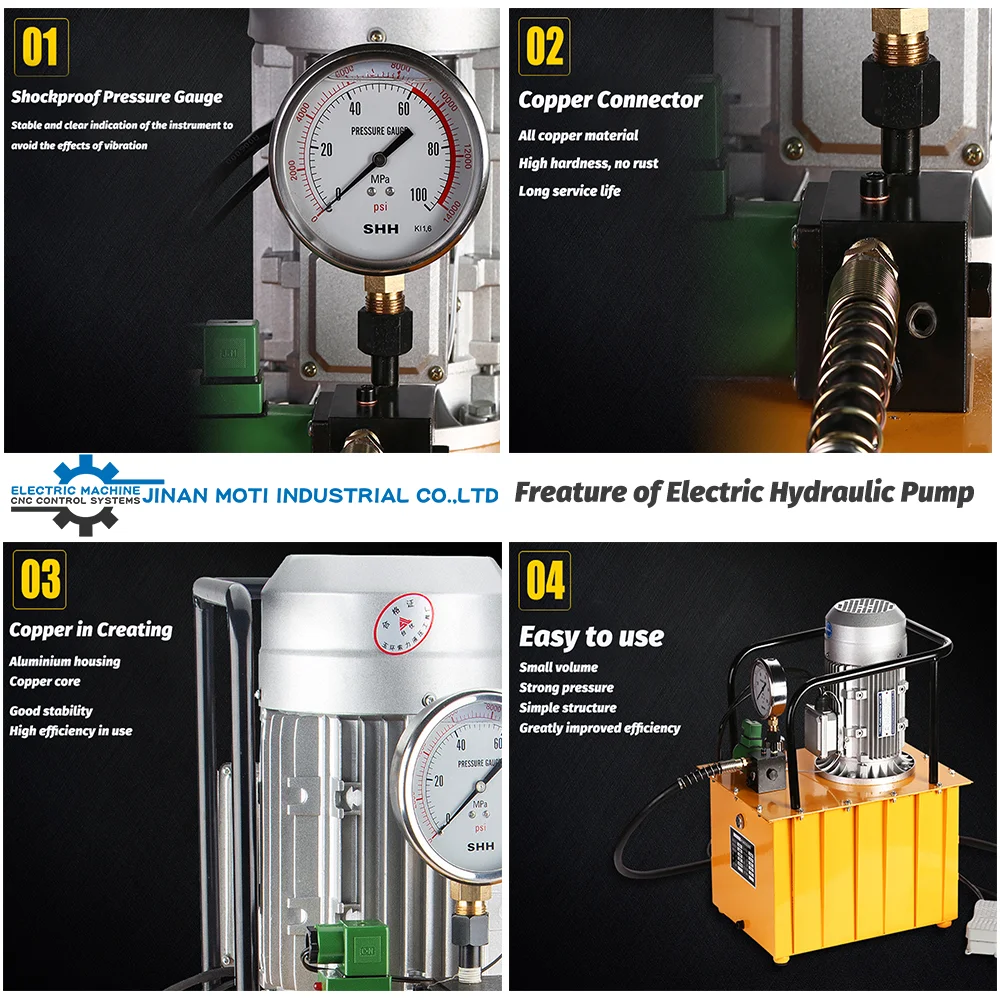

Features of electric hydraulic pump parts

Packed by wood box

How to use the electric hydraulic pump

When using, open the bleeder nut, open the switch on the oil collection block, plug in the power supply,

and set the quick connector on the quick head of the mating hydraulic apparatus, press the power switch, wait for the motor to rotate for 1-2 minutes,

close the switch and put it in the pressurised state, at this time the output hydraulic oil will carry out various work,

the output hydraulic oil will increase with the load and pressurise itself to carry out various work until 70Mpa,

after the work is finished After opening the switch to unload the hydraulic oil, remove the quick coupling sleeve,

screw the bleed nut, unplug the electric nai, and close the switch.

Common faults

1. Abnormal motor

Cause: Power supply not energized, poor contact with switch Solutions : Check the power switch

2. Abnormal pressure

Causes: (1) High pressure relief valve out of adjustment (2) Oil leakage; worn plunger

Solutions: (1) Adjust high pressure relief valve 70Mpa (2) Check and repair, replace the seal; replace the plunger

3. Insufficient flow rate

Cause: (1) Seal damage (2) incorrect hydraulic oil selection

Solutions: (1) Replace the seal (2) Use oil according to the instruction manual