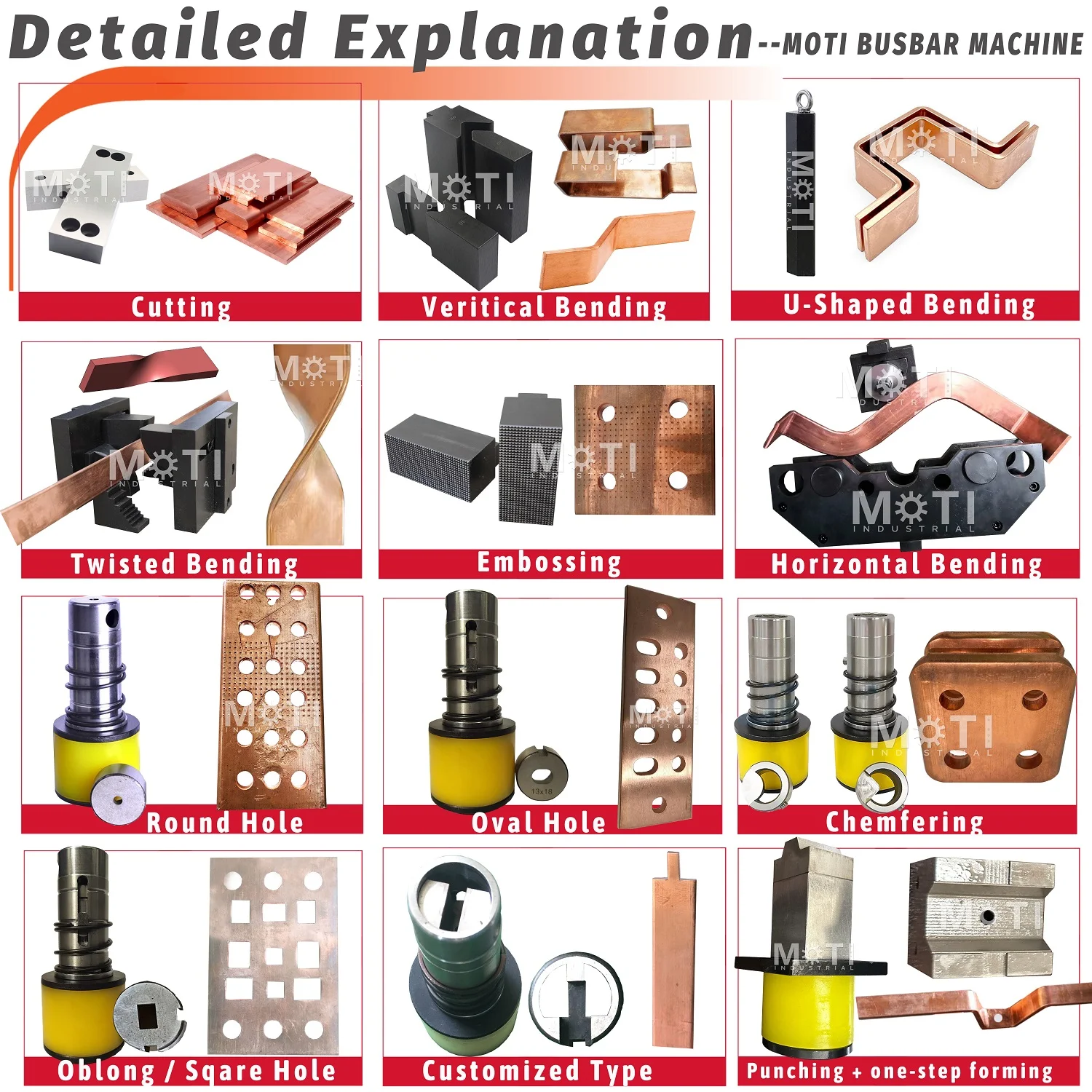

The Busbar Bending Punching Cutting Machine offered by MOTI INDUSTRIAL Group in China is a multifunctional tool used for bending, punching, and cutting copper and aluminum busbars used in switchboards, transformers, and other electrical applications.

16x250mm MOTI-50-3NC is a hydraulic copper busbar machine that can perform these three operations quickly and accurately, thereby reducing the production time and increasing the productivity of the electrical application.

The CNC Busbar Processing Machine MOTI-50-3NC has a sturdy construction, is easy to operate, and has a compact design that saves space and allows for easy transportation.

Overall, the MOTI INDUSTRIAL Group's Busbar Bending Punching Cutting Machine is a reliable and efficient solution for bending, punching, and cutting busbars and improving the productivity of electrical applications.

1 Cut Section of the CNC Busbar Cutting Punching and bending machine MOTI-50-3NC

#1.0 The copper busbar workpiece is flat and burr-free.

The busbar processing machine usually uses flat blade shearing. This method can make the surface of the workpiece flat after shearing without burrs.

For example, in the electrical complete set manufacturing industry such as high and low voltage switchgear and substation,

the surface flatness of the busbar is required to be high.

The use of busbar processing machine for shearing can meet this demand and ensure the quality of subsequent processing and use.

#2.0 No waste is generated.

The flat blade shearing method does not generate waste during the shearing process, which saves the cost of copper busbar materials to a certain extent and improves the utilization rate of materials.

It is of great significance for large-scale busbar processing and production.

#3.0 Structural design advantages: double-column integral structure.

The shearing unit of the busbar processing machine adopts a double-column integral structure. This design is novel and the force is reasonable.

It can effectively ensure that the shearing unit does not deform during long-term use, extend the service life of the equipment, and reduce problems such as reduced processing accuracy caused by equipment deformation.

2 Punching Section of CNC Busbar Processing Machine MOTI-50-3NC