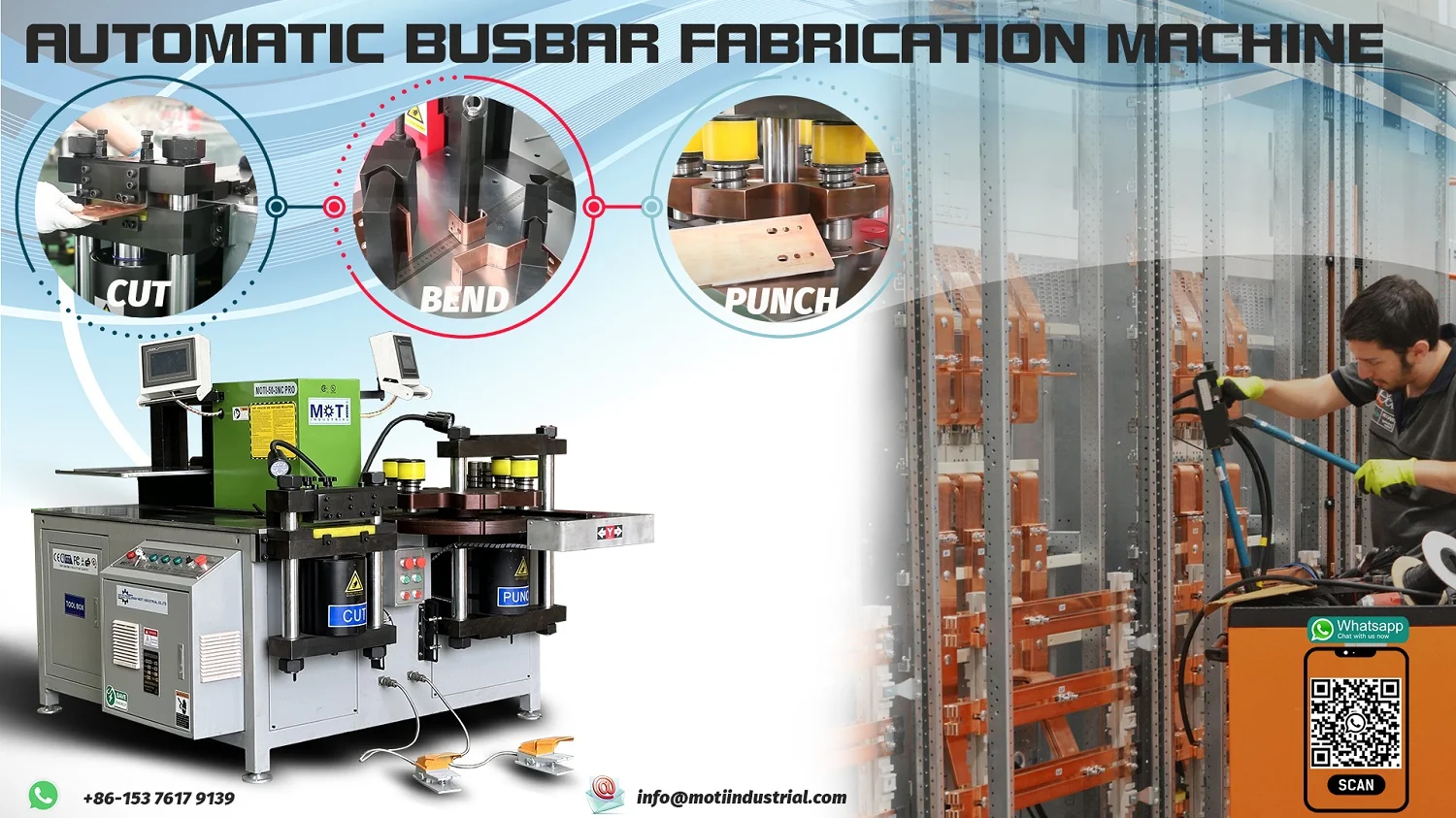

CNC Servo Copper Busbar Machine MOTI-30-3NC PRO to SPAIN

A CNC Busbar Processing Machine with Servo Automatic Positioning represents a significant advancement in busbar manufacturing technology, especially for industries requiring high precision and efficiency in producing busbars for electrical systems such as switchgear cabinets, transformers, and other high-voltage or low-voltage applications.

Key Features of a CNC Busbar Processing Machine with Servo Automatic Positioning:

Servo Motor Technology:

- The inclusion of servo motors allows for precise positioning and high-speed operation. These motors are highly responsive and capable of fine-tuning the machine’s movements, resulting in very accurate cuts, bends, and punches.

- Servo-driven positioning systems ensure that the busbars are consistently placed in the correct position for each operation, improving both the precision and reliability of the manufacturing process.

Automatic Positioning:

- The automatic positioning system eliminates the need for manual adjustment during setup, allowing for quicker changeovers between different busbar designs and configurations.

- The system automatically adjusts the position of the busbar material to ensure the machine can perform punches, cuts, and bends at the correct spots without manual intervention. This feature is particularly useful for high-volume production, as it increases speed while maintaining accuracy.

High Precision and Flexibility:

- The combination of CNC controls and servo positioning makes the machine extremely precise in terms of positioning, which is crucial when working with copper and aluminum busbars.

- With automated adjustments for different busbar sizes and configurations, the machine can easily accommodate a variety of shapes, improving production flexibility.

Multi-Functionality:

- Typically, these machines can punch, cut, and bend busbars of various sizes (e.g., up to 12x160 mm, or other configurations depending on the model), all within a single machine.

- These functions are often fully programmable, allowing users to store and repeat complex patterns and designs with minimal manual input.

Enhanced Cycle Time:

- The automatic positioning reduces the setup time between tasks, while the servo motors enable rapid movements, significantly improving cycle times and productivity.

- The system also allows for faster changeovers between different busbar sizes and designs, which is particularly useful in environments with high product variability.

Integrated Control Systems:

- The machine is typically equipped with a CNC controller that allows operators to input designs, monitor performance, and make real-time adjustments.

- The controller may feature user-friendly software that enables easy design entry, even for operators with minimal technical expertise. Some machines come with graphic interfaces to visualize the busbar shapes before production.

Material Handling and Safety Features:

- Advanced machines may include automatic material loading and unloading systems, further streamlining the production process.

- Built-in safety features, such as emergency stop buttons and protective shields, ensure safe operation of the machine.

Benefits for Manufacturers:

- Increased Accuracy: Servo automatic positioning ensures precise cutting, bending, and punching with minimal tolerance variations, leading to consistently high-quality busbars.

- Higher Efficiency: The ability to automatically adjust the position of the material for each operation reduces setup time and minimizes downtime, making the machine suitable for high-volume production.

- Flexibility: The machine can be easily reprogrammed to handle a range of busbar sizes and designs, providing manufacturers with the flexibility to respond quickly to customer demands.

- Reduced Labor Costs: Automation minimizes the need for manual adjustments, requiring fewer operators and reducing the risk of human error.

- Cost-Effective: The high-speed processing, coupled with minimal waste, leads to significant cost savings, especially in mass production environments.

Typical Applications:

- Electrical Switchgear: Producing busbars for medium and low-voltage electrical panels.

- Transformers: Fabricating busbars that connect various parts of electrical transformers.

- Power Distribution: Manufacturing busbars used in power distribution systems.

- Industrial Equipment: Custom busbars for large industrial machines and systems that require efficient power distribution.

In conclusion, a CNC Busbar Processing Machine with Servo Automatic Positioning is an advanced solution for manufacturers in the electrical industry, offering enhanced precision, flexibility, and productivity. These machines streamline the production of high-quality busbars while reducing operational costs, making them an essential tool for modern electrical manufacturing.