CNC busbar bending & punching cutting machine manufacturers

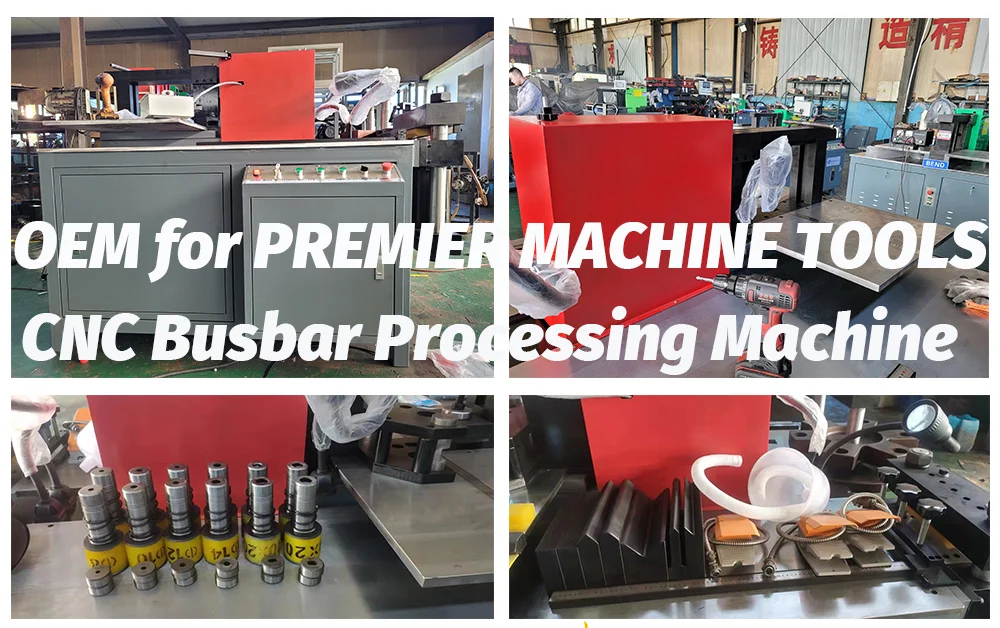

Our Indian dealer placed an order to us to customize 1 set of MOTI-50-3NC Busbar Processing Machine.

MOTI INDUSTRIAL Group is a professional CNC busbar bending & punching cutting machine manufacturers and suppliers in China, specialized in providing high quality OEM products.

Now, let's show you some featurers of the CNC Busbar Bending & Punching Cutting Machine.

1 Introduction of MOTI-50-3NC Busbar Processing Machine

(1) Capacity : 16mm x 250mm () Thickness x Width

(2) Bending Punching Cutting Three functions in one machine -- 3 in 1

The MOTI-50-3NC Busbar Processing Machine is equipped with punching cutting bending three units, and install 3 sets of electric motors and hydraulic pumps.

This hydraulic system can ensure three units can work at the same time,and will not influence each other.

(3) The structure for MOTI-50-3NC Busbar Processing Machine

The punching unit is turret structure,the bending unit is closed on the top,the bending Angle is with storage function.

The shearing position adopts a double pillar structure with flat shears, no waste, no burrs, and no collapse feet.

(4) SIEMENS CONTROL system

SIEMENS 40 PLC control system from German, which is with Automatic shutdown function,and can control the down time of cutting unit and punching unit,it is more stable and reliable than traditional relays.

The main function is processing different types of copper(brass) aluminum bus bar.

When it is working, worker just need to choose the unit,then machine will cutting and punching(holes,long holes square holes special holes),horizonal bending,vertical bending embossing flatting torsional Hemp flowers ect.

(5) More details about three working units

1.Punching unit is with nodular-cast-ironed and turrent typed turntable with 4/6/8 molds holes,which is a who one,

so that the holes for molds(the molds is processed by our processing center) with higher precision and the clearance of the molds and turntable is 0.00-0.03mm,improving the concentricity,

then the life of molds can be longer and need not change the molds so frequent.

By added punching position,the machine can locate x axis and y axis mechanical double direction location.

that makes workers need not to cross lines and make punching marks, then improving the operating efficiency and accuracy of punching.

2、Cutting unit is with double upright pillars and double blades cutting structure

the above blade and below blade are installated vertically parallelly ,make sure the cut smooth,no waste,no deformationfor longtime used.

3、Bending unit is with closed bendin,output point and force bearing force are connecting with beam of 50mm thickness,the mechanical strength is stronger than those open bendin.

4、Bending Angel is controlled by Numerical control system.Z bending can be processed through enter H (vertical height of above and below planes)and L(length of Hypotenuse)

2 If you want to check more detailed information of MOTI-50-3NC Busbar Processing Machine, check the below link,

https://www.motiindustrial.com/images/cnc_busbar_processing_machine_3_in_1_/288.html

3 More details about package and shipment for MOTI-50-3NC Busbar Processing Machine