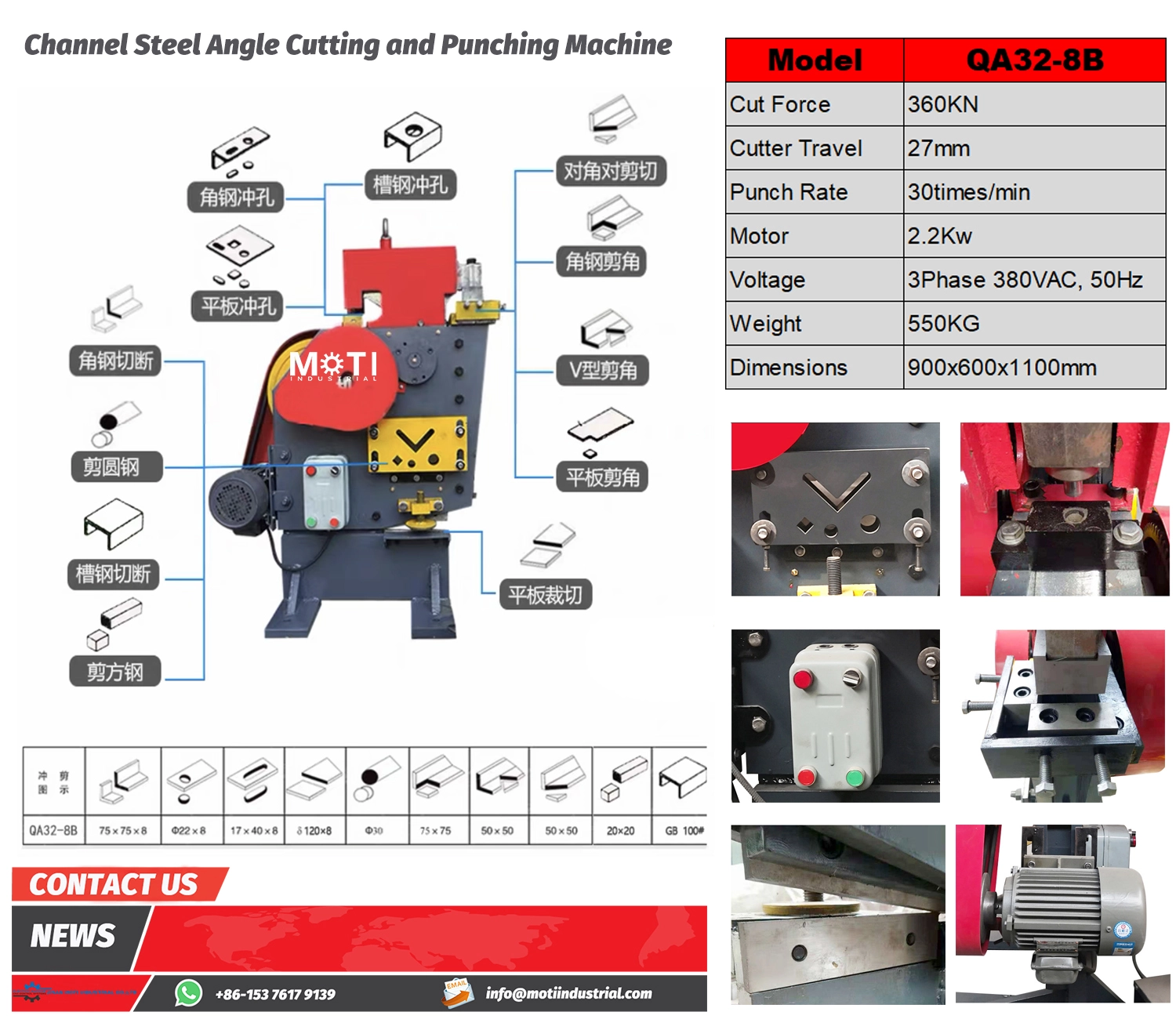

Multifunctional punching and shearing machine iron worker

Angle Steel Punching and Shearing Machine/Angle Iron Cutting Machine

Feature for Angle Steel Punch and shear Machine Iron Worker

#1. Steel structure processing

#2. Agricultural and animal husbandry machinery industry — thresher frame and trailer bucket parts processing

#3. Machinery for food industry — slaughtering equipment frame and parts processing

#4. Wind power equipment — processing of parts for stairs and pedals on wind power towers

#5. Mechanical processing — processing of embedded building parts/conveyor supports and other components that play a connecting role

#6. Railway truck/car, crane parts processing Channel steel, square steel, round steel, H steel, I-steel, and other steel products shear, punch, bend.

Introduction of Angle Steel Punch and shear Machine Iron Worker

The shearing machine which shearing sheet metal are the newly designed products of our factory and they are series products of machinery industry.

They are new in design,compact in structure,artistic in modeling,reliable in performance,small in size, light in weight, multi functional and quick in operation,

convenient in use and they are widely used in shearing sheet metal, shaped metal and punching shaped metal, holes and in die shearing,

It is really the skill ful equipment in shearing and punching shaped metal for the vast number of the customers in the industvies of machine making, buildingindustry, Hydropower industry and handicraft industry.

Multi-function punching and shearing machine is a mechanical cutting, shearing and punching processing equipment for metal materials. It utilizes overlapping two-stage levers, sliders, etc.,

To drive the slide plate with three kinds of shearing blades to move up and down, and the fixed blade mounted on the frame to complete the cutting and punching process.

The machine has a compact structure, small size, light weight and convenient operation.

Parameter of Angle Steel Punch and shear Machine Iron Worker

| Model | MOTI32-8B | MOTI32-12B |

| Punching diameter | 22*8mm | 31*12mm |

| Shear Angle | 75*75*8mm | 120*120*12mm |

| Shear round steel | 30mm | 40mm |

| Shear Square steel | 20*20mm | 35*35mm |

| Die cutting | L70*70*6mm | L100*100*12mm |

| Shear flat steel | 100*8mm | 320*12mm |

| Max pressure | 360KN | 900KN |

| Shear knife length | 200mm | 200mm |

| Cutting tool schedule | 27mm | 36mm |

| Travel times | 30times/min | 30times/min |

| Motor power | 2.2KW/380V | 4KW/380V |

| Total weight | 520kg | 1100kg |

| Size | 900*500*1100mm | 1100*600*1500mm |

| Custom-made special-shaped mold |