How to Calibrate Busbar Bending Machine

We should calibrate the bending molds before bending operation.

So,how to do that?----The Installation Distance Calibration.

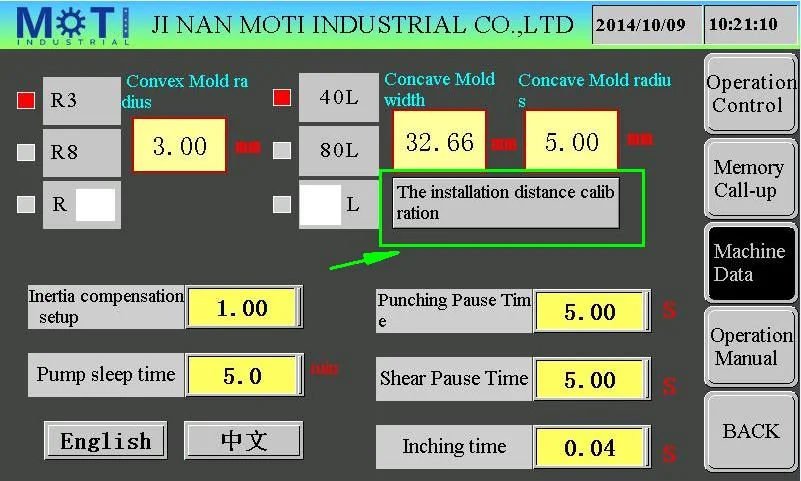

#1. Please find the below operation interface.

Select the R3 and 40L,fill in the data as the below image.

Then,click the button of The Installation Distance Calibration to enter the next step operation interface.

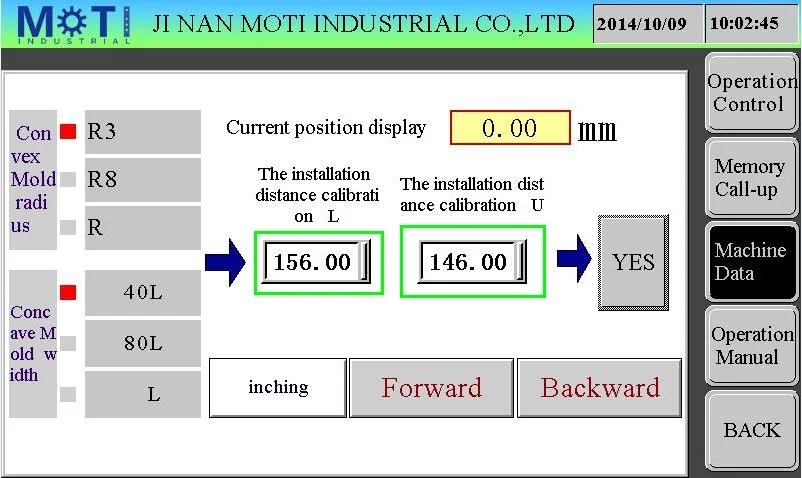

#2. Take the copper busbar with thickness of 10mm into the concave and the convex dies,

Touch the【Forward】button or step on foot switch to control the move of the die,

until the front end of die exactly contact the copper busbar.

(the copper busbar clamped by the concave and the convex die, but without deformation, inching fine adjustment is optional when the die come close to the copper busbar)

The installation distance of Model L ( or Model U) = the current position + 10mm

(So,why the current position should plus 10mm? Because,we use the copper busbar with thickness of 10mm to calibrate the bending molds,thus,

the current position should plus the copper busbar thickness)

Input installation distance, then click 【Yes】button and the calibration is done (shown as below).

(The below data from green circle is not constant (Fixed Value) ,please noted that)

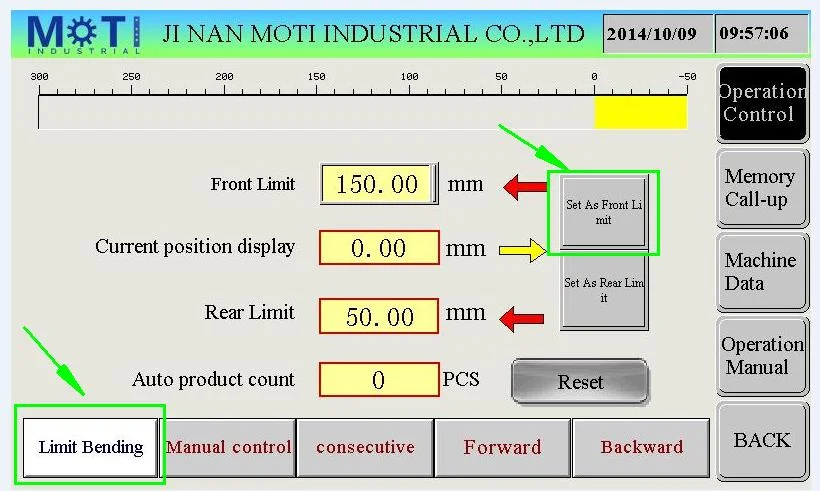

Then,touch the【Operation Control】button to enter the next step operation interface.

#3. Touch the【Limit Bending】button, make the " Current Position Display" to " Set As Front Limit"

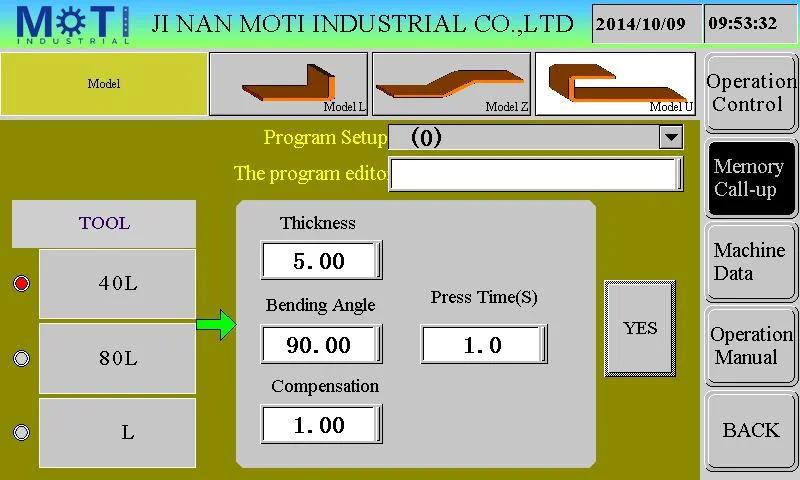

#4. Select your required "Model L", fill in the copper busbar thickness ( 10mm), Bending Angle (Your requried), Touch the "YES"

Attention:

1. Only one time Installation Distance Calibration is not suitable for different thicknesss of copper busbar.

In other words, this time you use the 10mm thickness copper busbar to finish Installation Distance Calibration,

if you use 5mm or 8mm other thickness copper busbar to bend, in the end you still can not get the accurate bending angle of copper busbar.

So, you need to do 5mm thickness copper busbar of Installation Distance Calibration.

You can use the different thickness of copper busbar to Installation Distance Calibration,then save the data into the machine.

(This fuction: the above picture: Program Setup,The program Editor)

2.

#1. If the bended copper busbar is less than 90 degrees, minus a bit of the value of the installation distance (-01mm, -0.2mm...);

#2. If the bended copper busbar is bigger than 90 degrees, plus a bit of the value of the installation distance(+01mm, +0.2mm...).

If you still can not solve this problem,send us yourself operation videos please.

We'll check and tell you the solutions.